A kind of preparation method of perovskite film and its application in perovskite solar cell

A solar cell and perovskite technology, which is applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as perovskite loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

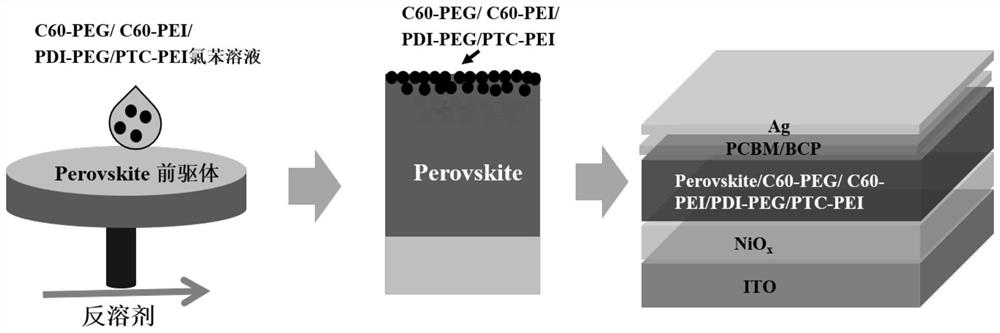

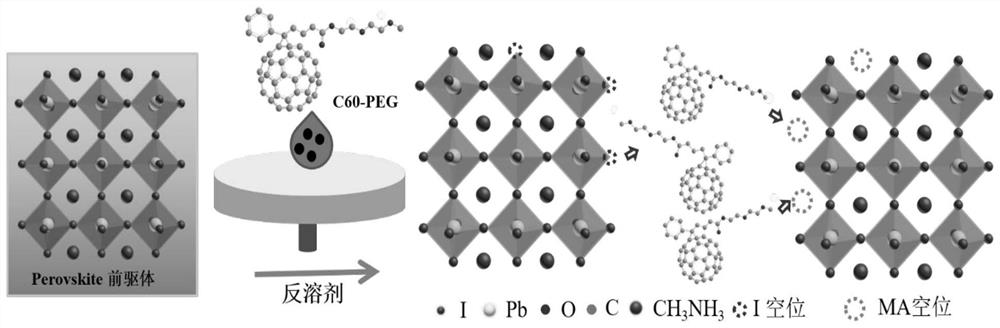

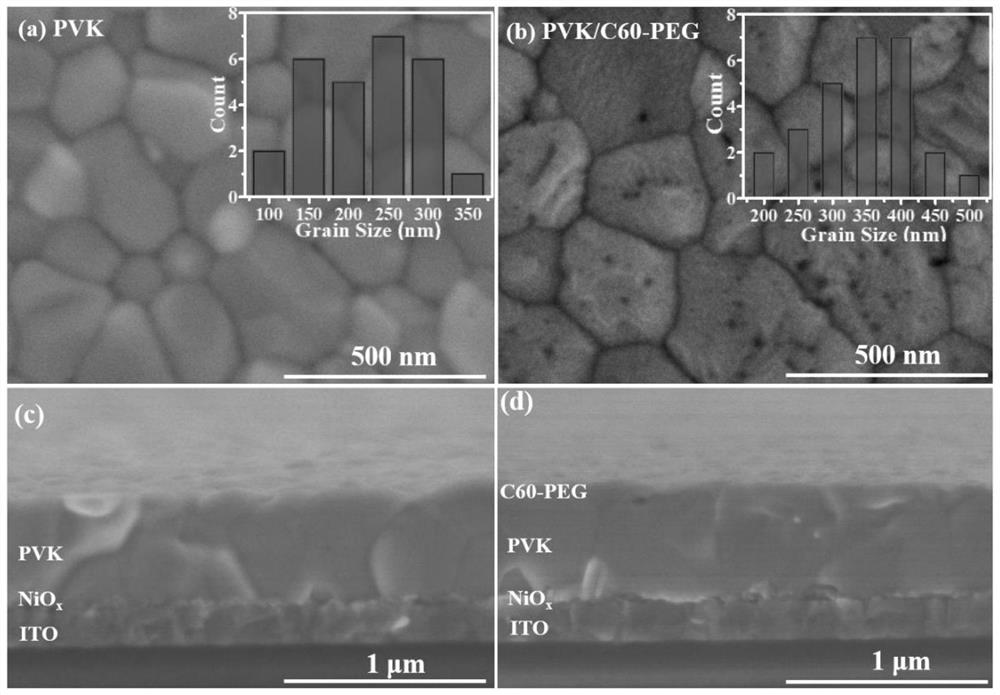

Method used

Image

Examples

preparation example Construction

[0032] (3) Preparation of polyethylene glycol perylene imide derivatives: Utilize N-methylpyrrolidone (NMP) as solvent, in dibromoperylene imide (PDI 2 Add a small amount of potassium carbonate (K 2 CO 3 ), heating to reflux, and column purification to obtain the product polyethylene glycol-modified perylene imide derivative (PDI-PEG). (n=35-255)

[0033]

[0034] (4) Preparation of polyethylene amine perylene imide derivatives: Perylenetetracarboxylic dianhydride (PTCDA) and polyethylene amine were reacted at 160 ° C for 4 h under the conditions of using imidazole as the reaction solvent and zinc acetate as the catalyst. Column purification yielded polyethyleneamine-modified peryleneimide derivatives (PTC-PEI) (n=25-115).

[0035]

Embodiment 1

[0036] Example 1: Preparation of lead-based perovskite solar cells with chlorobenzene solution anti-solvent.

[0037] Step 1: Clean the surface of ITO glass (1.5cm*1.5cm), and clean the surface with ultraviolet ozone for 10 minutes.

[0038] Step 2: Add 0.5mol Ni(NO 3 ) 2 ·6H 2 O was dispersed into 100mL deionized water, placed on a magnetic stirrer to dissolve, and after calibrating the pH meter with pH 4.01 and 7.13 calibration solutions, 10mol L -1 The pH was adjusted to 10 with NaOH solution. After stirring for 5 min, the obtained colloidal precipitate was divided into centrifuge tubes and washed twice with deionized water, followed by centrifugation, and the obtained precipitate was dried in an oven at 80° C. for 6 h. Put the obtained green powder into a muffle furnace for calcination at 270°C for 2 hours to obtain black powder NiO x Nanoparticles. NiO x Nanoparticles were dispersed in deionized water (20mg / mL), and NiO x nanoparticle dispersion. The NiO x The n...

Embodiment 2

[0042] Example 2: Preparation of lead-based perovskite solar cells using fullerene derivative [6,6]-phenyl-C61-butyric acid methyl ester (PCBM) anti-solvent.

[0043] In step 3 of Example 1, the chlorobenzene solution (2 mg / mL) of the fullerene derivative [6,6]-phenyl-C61-butyric acid methyl ester (PCBM) was substituted for the pure chlorobenzene solution to prepare perovskite film. All the other steps and methods are exactly the same as in the foregoing embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com