Fast bright quenching oil

A quenching oil, bright technology, applied in the direction of quenching agent, heat treatment equipment, manufacturing tools, etc., can solve the problem of uneven hardness, quenching crack, high viscosity, achieve good chemical stability and tolerance, excellent cooling ability, preparation simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

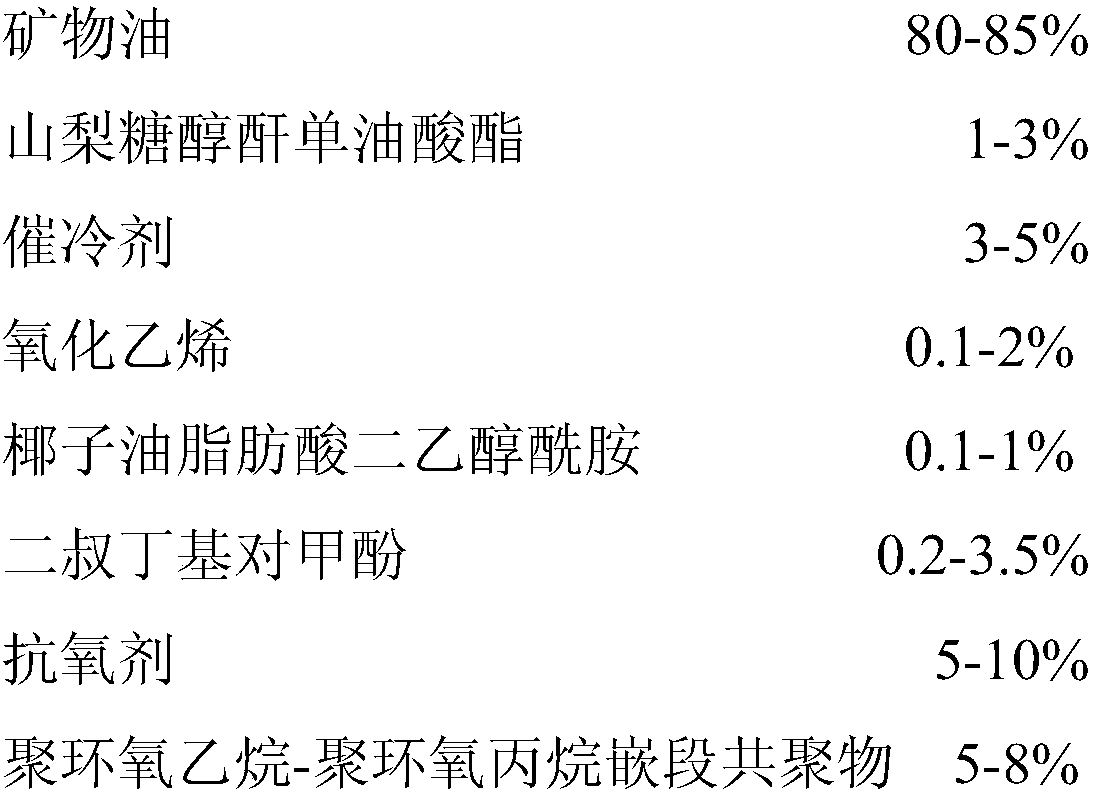

Method used

Image

Examples

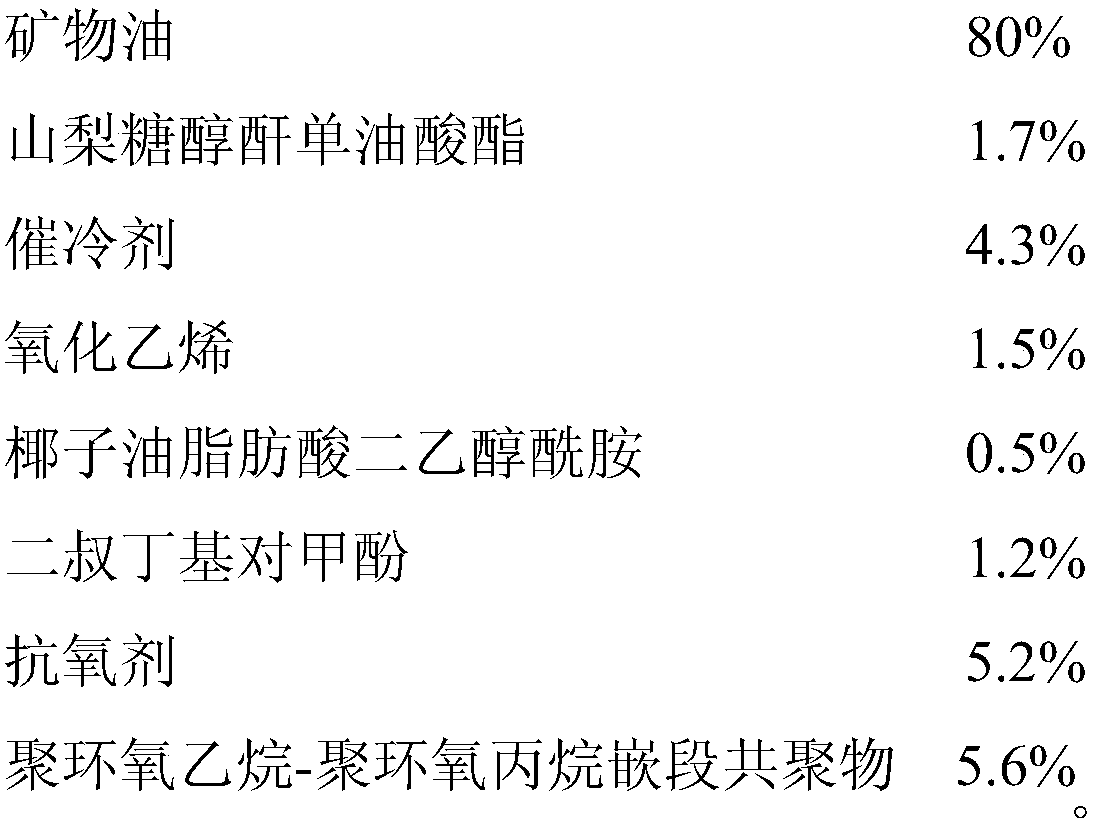

Embodiment 1

[0024] Preparation of antioxidants:

[0025] (1) Put diphenylamine into a four-neck round-bottomed flask, slowly drop diisobutene into it, diphenylamine and diisobutene are in a molar ratio of 1:3.2, control the reaction temperature at 135°C, react for 6 hours, and depressurize after the reaction The excess diisobutene in the distillation place is recycled;

[0026] (2) After the reaction product is lowered to room temperature, add ether to dissolve, stir evenly and then separate layers; wash the organic layer with water, distill the ether out under normal pressure, and dry the distilled product in a drying oven to obtain an antioxidant.

[0027] Preparation of fast bright quenching oil:

[0028] S1. 80kg of mineral oil is added to the reaction kettle, heated to 65°C, and 0.5kg of coconut oil fatty acid diethanolamide and 4.3kg of refrigerant are added under stirring, and the refrigerant is composed of barium petroleum sulfonate, polyisobutylene, The ethylene-propylene copol...

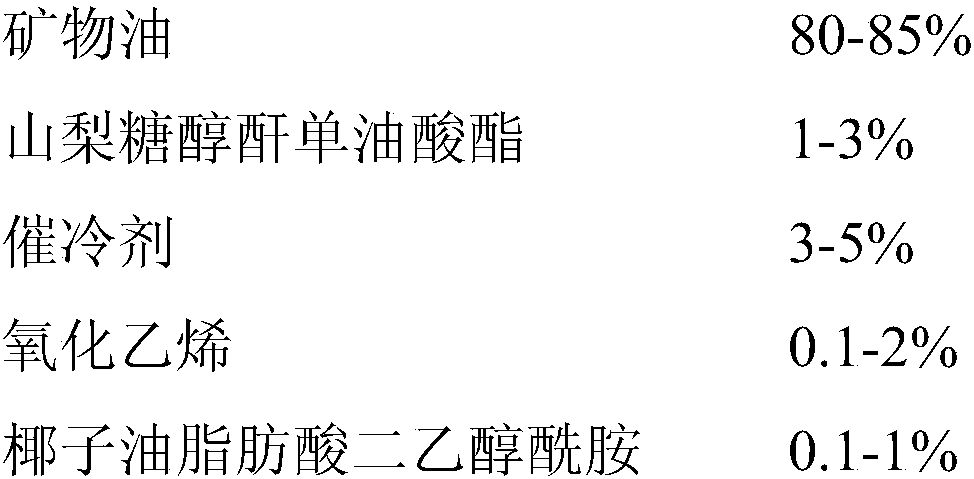

Embodiment 2

[0032] Antioxidant preparation:

[0033] (1) Put diphenylamine into a four-necked round-bottomed flask, slowly drop diisobutene into it, diphenylamine and diisobutene are in a molar ratio of 1:3.2, control the reaction temperature at 140°C, react for 5 hours, and depressurize after the reaction The excess diisobutene in the distillation place is recycled;

[0034] (2) After the reaction product is lowered to room temperature, add ether to dissolve, stir evenly and then separate layers; wash the organic layer with water, distill the ether out under normal pressure, and dry the distilled product in a drying oven to obtain an antioxidant.

[0035] Preparation of fast bright quenching oil:

[0036] S1. Add 83kg of mineral oil into the reactor, heat it to 75°C, add 1kg of coconut oil fatty acid diethanolamide and 3kg of refrigerant under stirring, and the refrigerant is composed of barium petroleum sulfonate, polyisobutylene, ethylene- The propylene copolymer is composed accordin...

Embodiment 3

[0040] Preparation of antioxidants:

[0041] (1) Put diphenylamine into a four-neck round-bottomed flask, slowly drop diisobutene into it, diphenylamine and diisobutene are in a molar ratio of 1:3.2, control the reaction temperature at 135°C, react for 6 hours, and depressurize after the reaction The excess diisobutene in the distillation place is recycled;

[0042] (2) After the reaction product is lowered to room temperature, add ether to dissolve, stir evenly and then separate layers; wash the organic layer with water, distill the ether out under normal pressure, and dry the distilled product in a drying oven to obtain an antioxidant.

[0043] Preparation of fast bright quenching oil:

[0044] S1. Put 80kg of mineral oil into the reaction kettle, heat it to 60-80°C, add 0.8kg of coconut oil fatty acid diethanolamide and 4.2kg of refrigerant under stirring state, and the refrigerant is composed of barium petroleum sulfonate, poly Isobutylene and ethylene-propylene copolyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com