Whitening and freckle removing mask liquid and preparation method thereof

A technology of whitening and freckle-removing facial mask liquid, which is applied in the field of whitening and freckle-removing facial mask liquid and its preparation. It can solve the problems of complex skin problems that cannot be treated and improved, increased skin melanin, unstable efficacy, etc., and achieve the purpose of inhibiting the disorder of epidermal cell function, Reduces the production of melanin and alleviates the effects of the emergency response mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

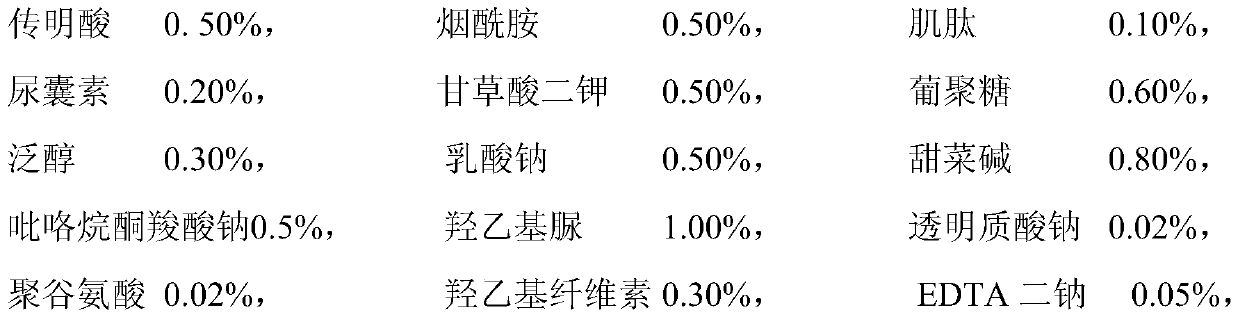

[0025] Weigh each component according to the following weight percentages:

[0026]

[0027]

[0028] Weigh each component by weight percentage, put deionized water into the vacuum emulsification pot, heat up to 95°C for 20 minutes, cool to 75°C, put EDTA disodium into the deionized water under stirring, mix hydroxyethyl cellulose, Add sodium hyaluronate, polyglutamic acid and butanediol after mixing, keep the temperature at 60-75°C, stir until dissolved evenly; cool down to 45-50°C, add glycerin, tranexamic acid, nicotinamide, allantoin, Dipotassium glycyrrhizinate, dextran, panthenol, betaine, stir until dissolved evenly; cool down to 35-45°C, add carnosine, sodium lactate, sodium pyrrolidone carboxylate, hydroxyethyl urea, hydroxyphenylpropanamide benzoic acid, Phenoxyethanol, hexanediol, and methylparaben were stirred until uniformly dissolved; vacuumed to -0.06MPa, stirred for 20 minutes; vacuum was removed, and the material was discharged. Various index tests were...

Embodiment 2

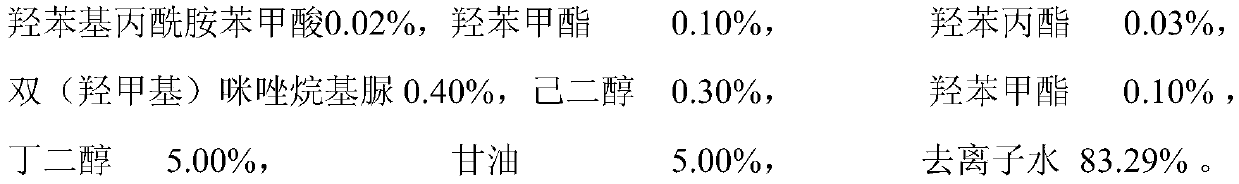

[0030] Weigh each component according to the following weight percentages:

[0031]

[0032] Weigh each component by weight percentage, put deionized water into the vacuum emulsification pot, heat up to 95°C for 20 minutes, then cool to 75°C, put EDTA disodium into the deionized water under stirring, add carbomer, hyaluronic acid Add sodium bicarbonate, polyglutamic acid and methyl propylene glycol after mixing, keep the temperature at 60-75°C, stir until dissolved evenly; cool down to 45-50°C, add glycerin, tranexamic acid, nicotinamide, allantoin, glycyrrhizic acid Dipotassium, dextran, panthenol, betaine, stir until dissolved evenly; cool down to 35-45°C, add carnosine, sodium lactate, sodium pyrrolidone carboxylate, hydroxyethyl urea, hydroxyphenylpropanamide benzoic acid, phenoxy Ethanol, p-hydroxyacetophenone, and hexanediol, stirred until dissolved evenly; vacuumed to -0.06MPa, dissolved arginine in the process water, sucked into the vacuum emulsification pot, stirre...

Embodiment 3

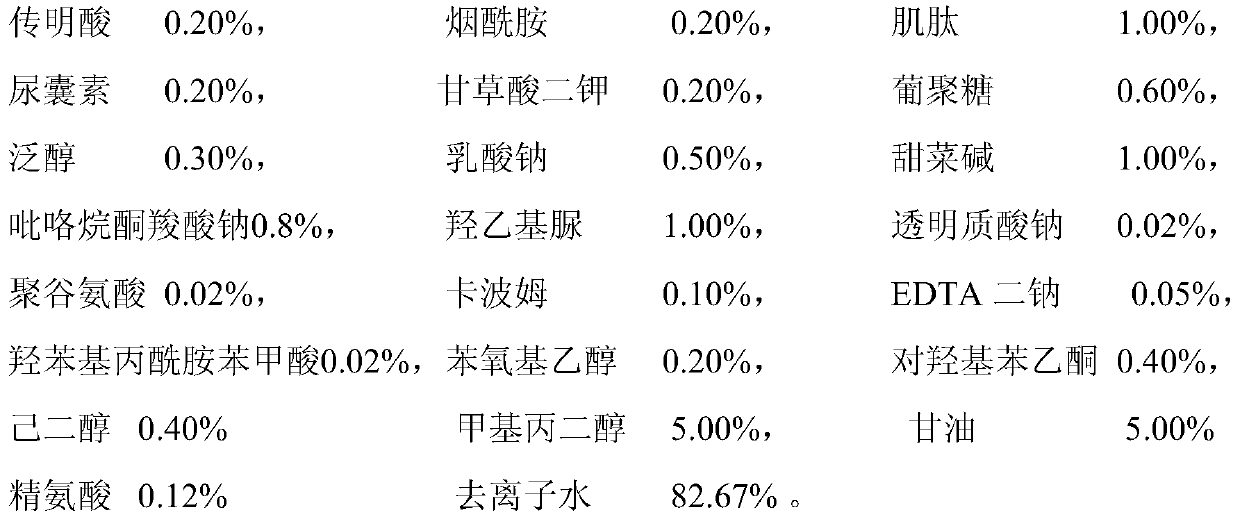

[0034] Weigh each component according to the following weight percentages:

[0035]

[0036]Weigh each component by weight percentage, put deionized water into the vacuum emulsification pot, heat up to 95°C for 20 minutes, cool to 75°C, put EDTA disodium into the deionized water under stirring, mix hydroxyethyl cellulose, Add xanthan gum, sodium hyaluronate, polyglutamic acid and propylene glycol after mixing, keep the temperature at 60-75°C, stir until dissolved evenly; cool down to 45-50°C, add glycerin, methylparaben, tranexamic acid, Niacinamide, allantoin, dipotassium glycyrrhizinate, dextran, panthenol, betaine, stir until dissolved evenly; cool down to 35-45°C, add carnosine, sodium lactate, sodium pyrrolidone carboxylate, hydroxyethylurea, hydroxy Phenylpropionamide benzoic acid, phenoxyethanol, pentylene glycol, and hexanediol, stirred until uniformly dissolved; vacuumed to -0.06MPa, stirred for 30 minutes; vacuum removed, and discharged. Various index tests were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com