Preparation method of carbon cloth-based ferric cobaltate/molybdenum disulfide graded structure electrode material

A carbon cloth-based cobalt acid and molybdenum disulfide technology, which is applied in the field of preparing carbon cloth-based iron cobaltate/molybdenum disulfide hierarchical structure electrode materials, can solve the problem of high theoretical capacitance of molybdenum disulfide and ineffective utilization of active sites , easy to reunite and other problems, to achieve the effect of ensuring cycle stability, less destructive, and improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

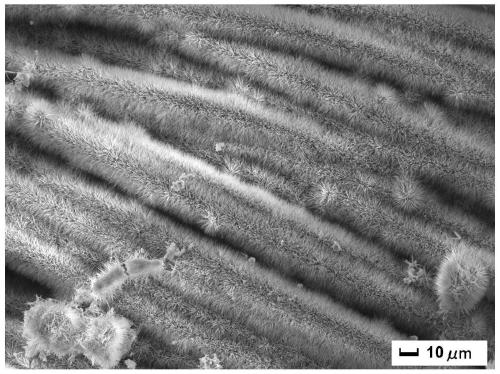

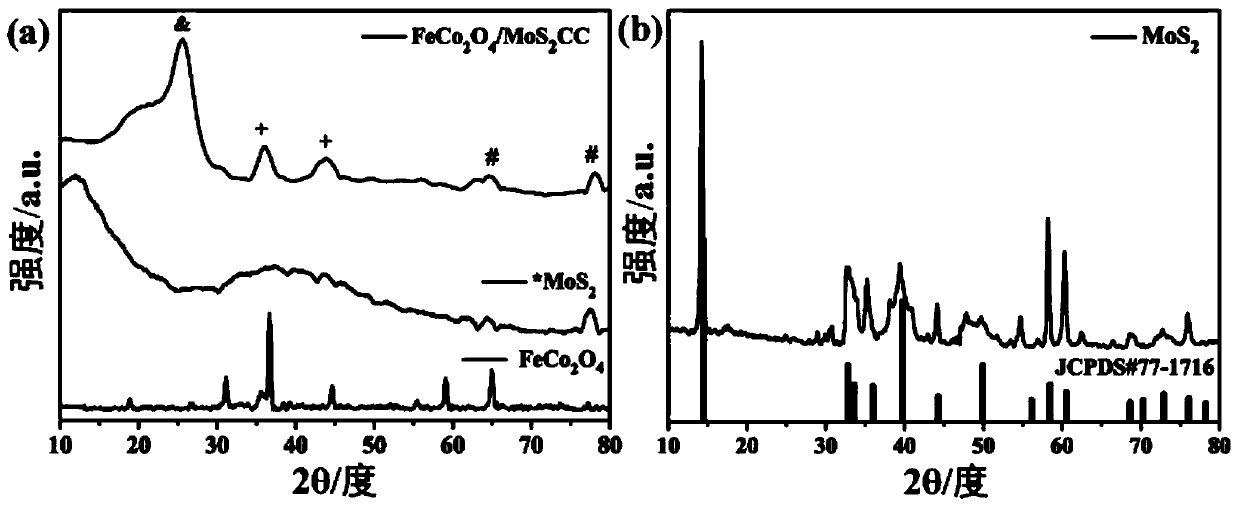

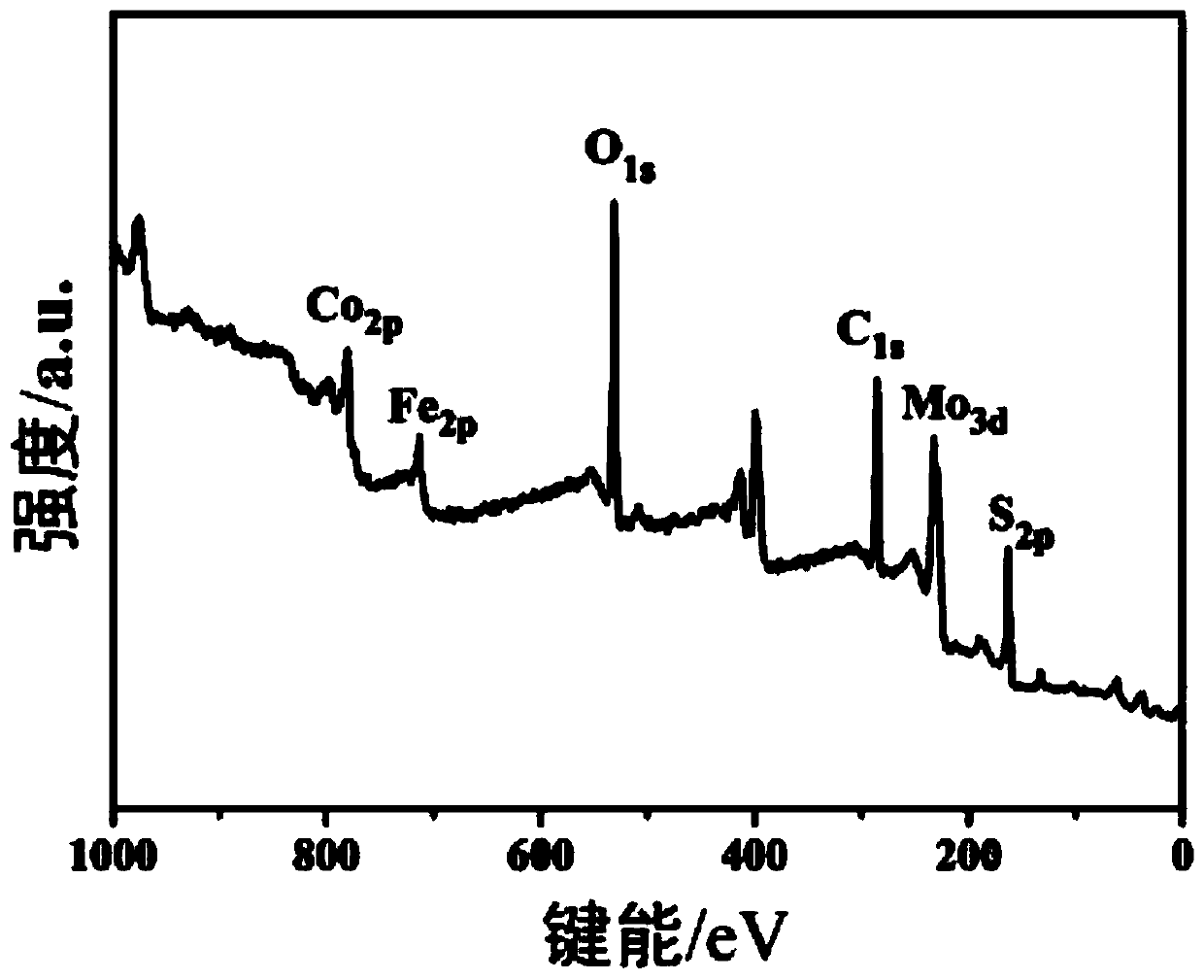

[0035] Step 1. Preparation of carbon cloth-based iron cobaltate nanorod arrays:

[0036] Firstly, the carbon cloth is cut, the length and width are 3×1 cm, the carbon cloth is ultrasonically washed in acetone, 30% hydrochloric acid, deionized water and ethanol solution, and dried to obtain a dry carbon cloth; then take Add 1 mol of cobalt nitrate, 0.5 mol of ferric nitrate, 0.15 mol of ammonium fluoride, and 0.2 mol of urea powder into 40 mL of distilled water, sonicate for 10 min, stir with a magnetic stirrer for 20 min, and mix evenly to obtain ferric cobaltate The precursor solution was transferred to a stainless steel reaction kettle, and continued to heat up to 120°C for 12 hours, then cooled to room temperature, and the product was taken out, washed several times, dried in vacuum, and then put into a tube furnace for calcination at 400°C. The calcination speed was 3°C / min, keep warm for 1h to obtain carbon cloth-based iron cobaltate nanorod arrays;

[0037] Step 2, prep...

Embodiment 2

[0040] Step 1. Preparation of carbon cloth-based iron cobaltate nanorod arrays:

[0041] Firstly, the carbon cloth is cut, the length and width are 3×1 cm, the carbon cloth is ultrasonically washed in acetone, 30% hydrochloric acid, deionized water and ethanol solution, and dried to obtain a dry carbon cloth; then take Add 0.5 mol of cobalt nitrate, 0.25 mol of ferric nitrate, 0.12 mol of ammonium fluoride, and 0.15 mol of urea powder into 120 mL of distilled water, sonicate for 10 minutes, and stir with a magnetic stirrer for 20 minutes to mix evenly to obtain cobalt acid The iron precursor solution was transferred to a stainless steel reactor, and continued to heat up to 100°C for 24 hours, then cooled to room temperature, and the product was taken out, washed several times and dried in vacuum, then put into a tube furnace for calcination at 450°C, the calcination speed At 4°C / min, keep warm for 2 hours to obtain carbon cloth-based iron cobaltate nanorod arrays;

[0042] Step...

Embodiment 3

[0045] Step 1. Preparation of carbon cloth-based iron cobaltate nanorod arrays:

[0046] Firstly, the carbon cloth is cut, the length and width are 3×1 cm, the carbon cloth is ultrasonically washed in acetone, 30% hydrochloric acid, deionized water and ethanol solution, and dried to obtain a dry carbon cloth; then take Add 0.05 mol of cobalt nitrate, 0.025 mol of ferric nitrate, 0.1 mol of ammonium fluoride, and 0.1 mol of urea powder into 20 mL of distilled water, sonicate for 10 min, stir with a magnetic stirrer for 20 min, and mix well to obtain cobalt acid The iron precursor solution was transferred to a stainless steel reactor, and continued to heat up to 180°C for 24 hours, then cooled to room temperature, and the product was taken out, washed several times and dried in vacuum, then put into a tube furnace for calcination at 500°C, the calcination speed At 5°C / min, keep warm for 1h to obtain carbon cloth-based iron cobaltate nanorod arrays;

[0047] Step 2. Preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com