A kind of denitrification accelerator and its application

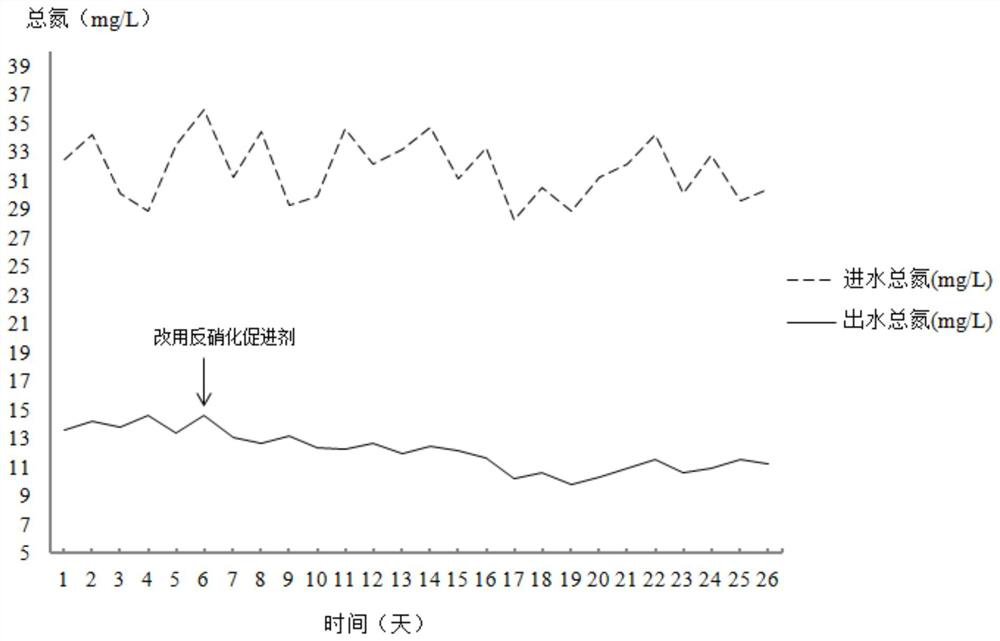

An accelerator, denitrification technology, applied in anaerobic digestion treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of unstable biological denitrification effect, low denitrification efficiency, and large dosage. , to achieve the effect of strengthening the microbial diversity of the system, saving the investment of civil construction funds, and improving the impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The present embodiment provides a denitrification accelerator, which includes the following components:

[0094] (1) Glycerol 750kg

[0095] (2) Mineral elements 10kg, including Co(NO 3 ) 2 ·6H 2 O 3.95kg (cobalt 0.8kg), ZnCO 3 4.6kg (zinc 2.4kg), Mn(NO 3 ) 2 ·H 2 O 1.37kg (manganese 0.3kg), MgCO 3 ·3H 2 O 11.36kg (magnesium 2kg), NiNO 3 ·6H 2 O7.43kg (nickel 1.5kg), Na 2 MoO 4 2H 2 O 1.26kg (molybdenum 0.5kg), Fe 2 (SO 4 ) 3 17.85kg (iron 2.5kg)

[0096] (3) 10kg of organic acids, including 5kg of citric acid, 1.5kg of acetic acid, and 3.5kg of nucleotides

[0097] (4) 12kg of biological enzymes, including 4kg of protease, 3kg of cellulase, and 5kg of lipase

[0098] (5) Organic salt 25kg, including sodium gluconate 12kg, sodium citrate 13kg

[0099] (6) Carbohydrate 1.5kg, including chitosan 1.5kg

[0100] (7) Anionic surfactant 2kg

[0101] (8) Algae matter 1.5kg

[0102] Mix the above raw materials, add water to a total weight of 1000kg, stir...

Embodiment 2

[0104] The present embodiment provides a denitrification accelerator, which includes the following components:

[0105] (1) Glycerol 800kg

[0106] (2) Mineral elements 10kg, including Co(NO 3 ) 2 ·6H 2 O 3.95kg (cobalt 0.8kg), ZnCO 3 4.6kg (zinc 2.4kg), Mn(NO 3 ) 2 ·H 2 O 1.37kg (manganese 0.3kg), MgCO 3 ·3H 2 O 11.36kg (magnesium 2kg), NiNO 3 ·6H 2 O7.43kg (nickel 1.5k), Na 2 MoO 4 2H 2 O 1.26kg (molybdenum 0.5kg), Fe 2 (SO 4 ) 3 17.85kg (iron 2.5kg)

[0107] (3) 10kg of organic acids, including 5kg of citric acid, 1.5kg of acetic acid, and 3.5kg of nucleotides

[0108] (4) 10kg of biological enzymes, including 3kg of protease, 3kg of cellulase, and 4kg of lipase

[0109] (5) Organic salt 15kg, including sodium gluconate 6kg, sodium citrate 9kg

[0110] (6) Carbohydrate 1.5kg, including chitosan 1.5kg

[0111] (7) Anionic surfactant 2kg

[0112] (8) Algae matter 1.5kg

[0113] Mix the above raw materials, add water to a total weight of 1000kg, stir in...

Embodiment 3

[0115] The difference from Example 1 is that iron is not included in the mineral elements, the mass of manganese in the mineral elements is 0.28kg, and the mass of zinc is 2.22kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com