Preparation method of MoSe2 in-plane homogeneous p-n junction

An n-type, field-effect transistor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as long time consumption, weak interaction force, and hindering TMDCs doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a MoSe 2 A method for preparing an in-plane homogeneous p-n junction, comprising the steps of:

[0034] (1) Provide MoSe 2 Field Effect Transistor;

[0035] (2) along the perpendicular to the MoSe 2 The direction of the field effect transistor electrode protects part of the channel close to the source or drain, and the partially protected MoSe 2 Field Effect Transistor;

[0036] (3) The partially protected MoSe 2 Field-effect transistors undergo UV-ozone treatment to obtain MoSe 2 In-plane homogeneous p-n junction.

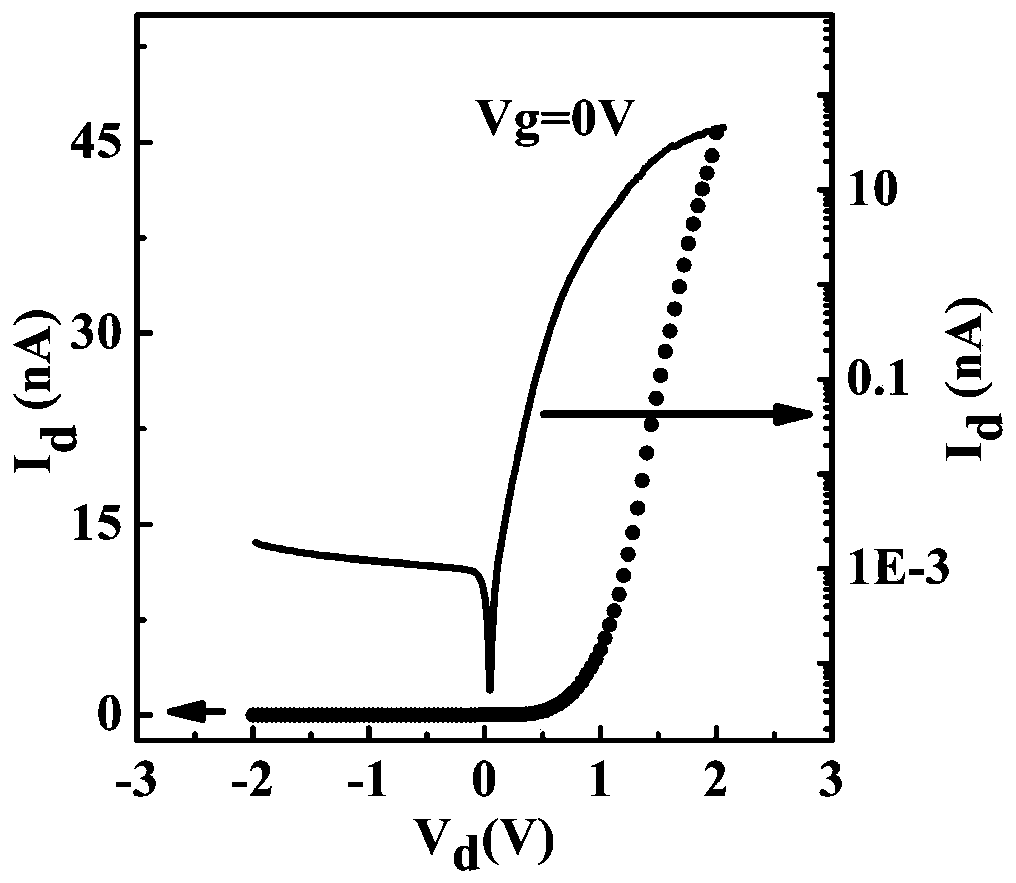

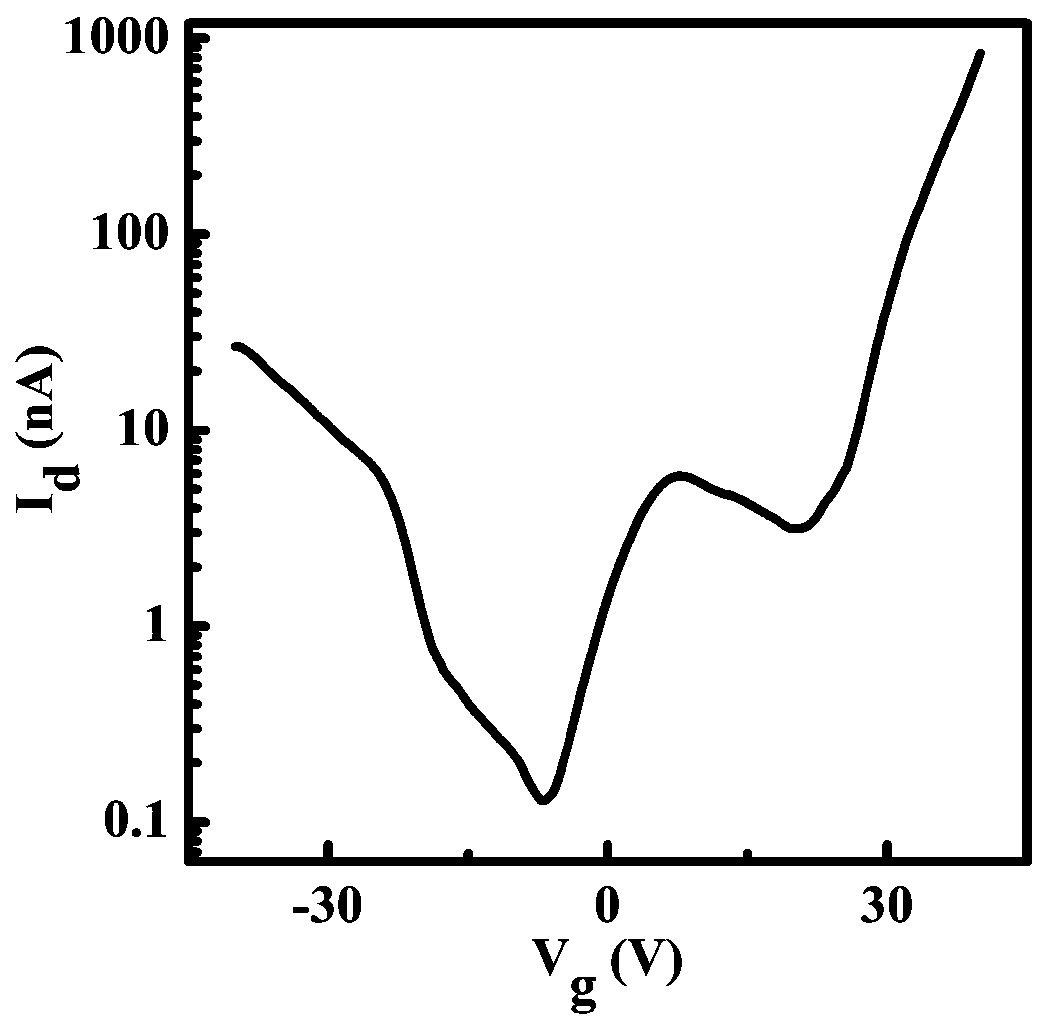

[0037] The present invention uses MoSe 2 A part of the field effect transistor channel is protected, and then treated with ultraviolet ozone, and the exposed channel is under the strong oxidation of ultraviolet ozone, MoSe 2 MoO with high work function will be formed on the surface x , resulting in electrons from MoSe with lower work function 2 Transfer to MoO x , so the exposed MoSe 2 It shows hole conduction, whi...

Embodiment 1

[0073] Select n-type SiO with 300nm thick oxide layer 2 / Si as the substrate, wash the substrate in an ultrasonic oscillator with deionized water, acetone, and isopropanol in sequence, then dry the substrate with a nitrogen gun, and place it on a hot plate at 90 °C for later use;

[0074] A little bulk MoSe 2 Placed on the blue film tape, folded in half repeatedly 6 times until the MoSe 2 Uniformly distributed on the tape, MoSe will stick 2 The tape aligns the SiO 2 / Si substrate is pasted on, after repeated extrusion with a beaker, the tape is peeled off, MoSe with different layers 2 Randomly distributed on SiO 2 / Si, in n-type SiO 2 / Si substrate to get MoSe 2 layers; few-layer MoSe can be discerned using an optical microscope that can coordinate 2, and then further determine the number of layers by Raman spectroscopy, which is 5 to 6 layers;

[0075] In the MoSe 2 Spin-coat PMMA glue (molecular weight: 950K) on the layer at a speed of 4000r / min. After spin-coating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com