Allogeneic demineralized bone material used for nose job filling and preparation method thereof

A bone material and demineralization technology, applied in nose implants, medical science, prostheses, etc., can solve the problems of high degree of costal cartilage calcification, limited material sources, difficult to shape, etc., and achieve good biocompatibility , The production process is simple and the effect is not easy to shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

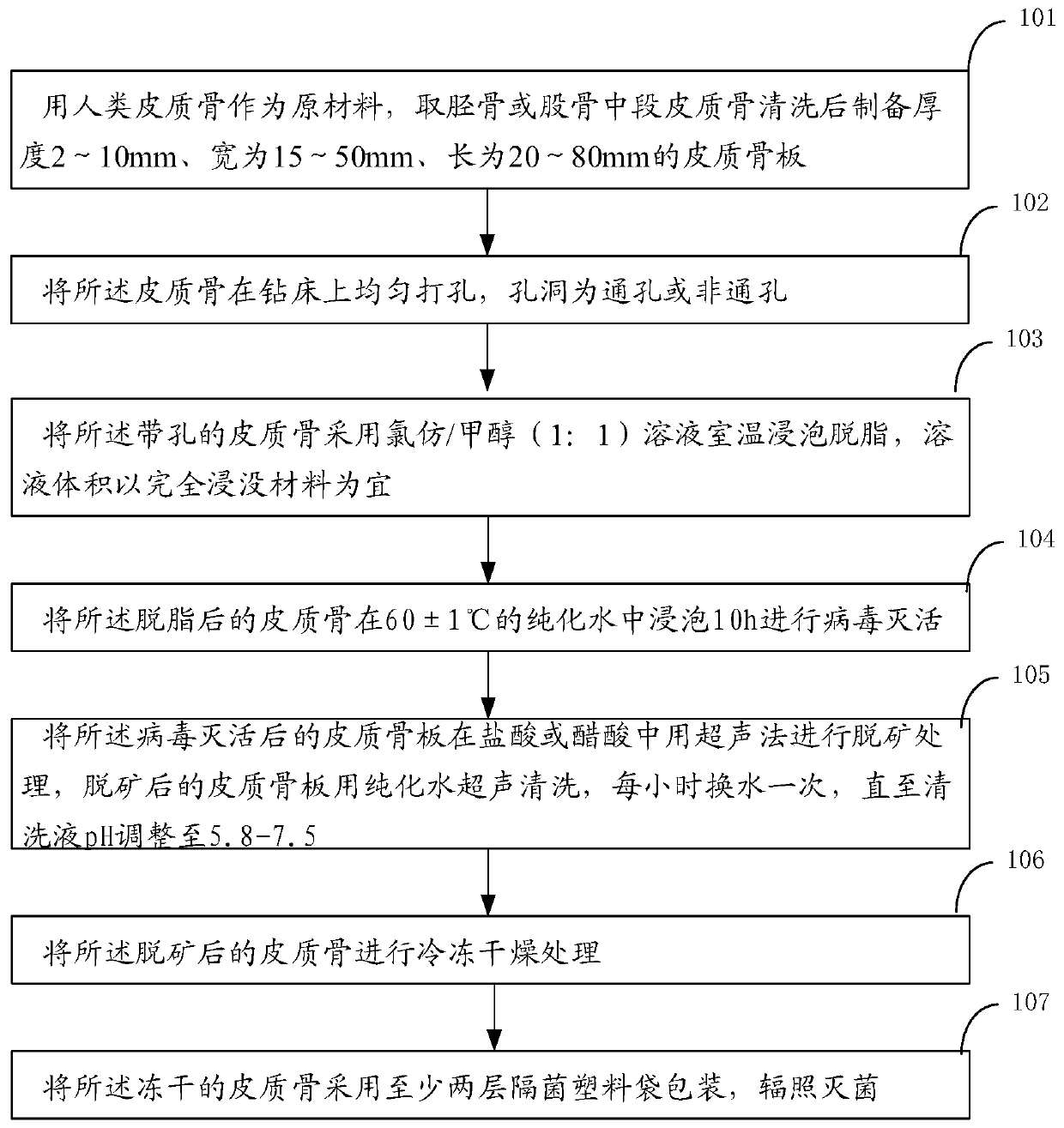

[0033] A method for preparing the same demineralized bone material used for rhinoplasty filling, comprising the following steps:

[0034] Step 101: Using human cortical bone as a raw material, take the middle tibia or femur cortical bone and wash it to prepare a cortical bone plate with a thickness of 2-10 mm, a width of 15-50 mm, and a length of 20-80 mm.

[0035] Step 102: Drilling the cortical bone evenly on a drill, and the holes are through holes or non-through holes.

[0036] Preferably, the hole diameter of the cortical bone is 0.2-2 mm, and the hole density is 20-50 holes / cm 2 .

[0037] Step 103: Soak the perforated cortical bone in chloroform / methanol (1:1) solution at room temperature to degrease.

[0038] Soaking and degreasing specifically includes: soaking in a mixed solution of chloroform / methanol with a volume ratio of 1:1 at room temperature for at least 24 hours during degreasing.

[0039] Step 104: Soak the defatted cortical bone in purified water at 60±1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com