Pickering emulsion polymerization based imidazole antifungal drug molecular imprinted functionalized microsphere, and amplification preparation method and application thereof

A Pickering emulsion and antifungal technology, which is applied to the preparation of microspheres, microcapsule preparations, etc., can solve problems such as being unfavorable for high-quality large-scale production, and achieve the effects of simple and reliable preparation method, simple equipment and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

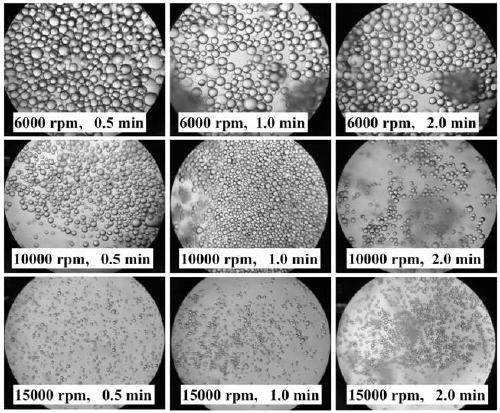

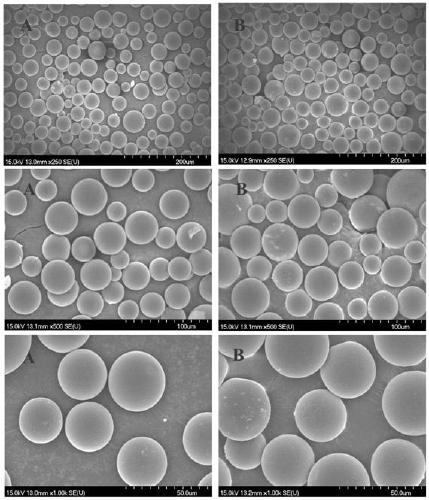

[0028] Example 1 Optimization of Preparation Conditions and Morphological Characterization of Pickering Emulsion Polymerized Molecularly Imprinted Microspheres

[0029] (1) 3.855g (15mmol) substituted template molecule [1-(2,4-dichlorophenyl)-2-(1-H-imidazole)ethanol)], 5.3mL (60mmol) functional monomer (methyl Acrylic acid), 57.0mL (300mmol) crosslinking agent (ethylene glycol dimethacrylate), and 600mg initiator (azobisisobutyronitrile) were dissolved in 56.0mL porogen (toluene), and ultrasonically mixed for 5 -15min to obtain a pre-polymerization solution.

[0030] (2) Ultrasonic dispersion of 450 mg of silica nanoparticles in 150.0 mL of Triton X-100 aqueous solution with a mass concentration of 0.2% to obtain an aqueous phase dispersion.

[0031] (3) Mix the above-mentioned pre-polymerization solution and the aqueous phase dispersion liquid, disperse the polymer Pickering emulsion by using a high-speed shear emulsifier, and seal it under a nitrogen atmosphere.

[0032] ...

Embodiment 2

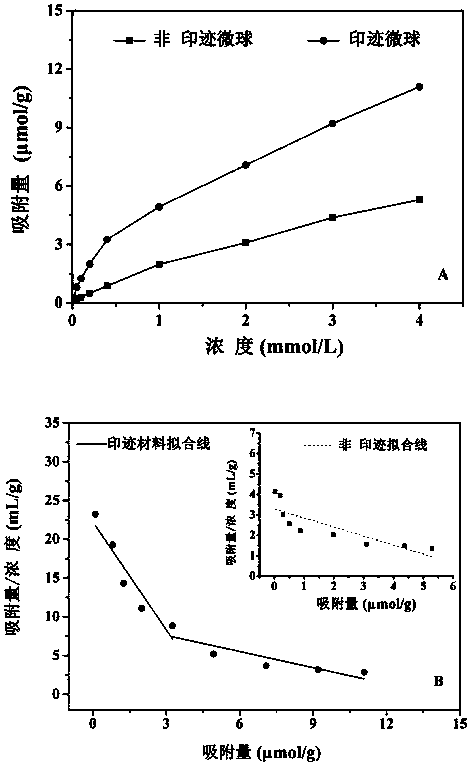

[0037] Example 2 Evaluation of Adsorption Performance of Pickering Emulsion Imprinted Polymer Microspheres on Imidazole Antifungal Drugs (1) Adsorption Isotherm Curve and Scatchard Analysis

[0038] Use acetonitrile as solvent to prepare a series of standard solutions of Campanola, with a concentration range of 0.005-4.0mM; weigh 20mg of imprinted or non-imprinted microspheres into a 10mL volumetric flask, add 2mL of standard solutions of different concentrations, seal and shake at 150rpm (25°C) 24h to reach adsorption equilibrium. After filtration, the supernatant was taken for liquid chromatography determination. The calculation formulas of adsorption capacity and adsorption equilibrium constant are:

[0039]

[0040] product; m (g) is the mass of imprinted or non-imprinted microspheres used; Q and Q max (μmol g -1 ) are the adsorption amounts of campanola in equilibrium and saturated adsorption, respectively. Using the above calculated data to make adsorption isother...

Embodiment 3

[0043] Example 3 Pickering emulsion imprinted microspheres are used for matrix solid phase dispersion extraction purification of imidazole antifungals in fish meat

[0044] The fish used in the experiment were collected from the local market. The bones and skin of the fish were removed, and the fish meat was mashed with a tissue grinder and stored at -20°C. Weigh 250 mg imprinted microsphere material and place it in a glass mortar, weigh 200 mg fish sample and place it on top of the material, add an appropriate volume of imidazole antifungal drug standard sample to the fish sample, and place it in a dark place at room temperature for 60 min. The control group was treated in the same way as above, except that the imprinted material was replaced with non-imprinted material. After standing still, add 200 μL of water into the glass mortar, mix and grind for 5 minutes to form a uniform mixture of the material and the fish sample. The homogeneous mixture was transferred to a 3 mL s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com