Preparation method of anode composition, anode composition and lithium ion battery

A composition and lithium-ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as reduction, impact on cathode material performance, etc., and achieve the effect of improving material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

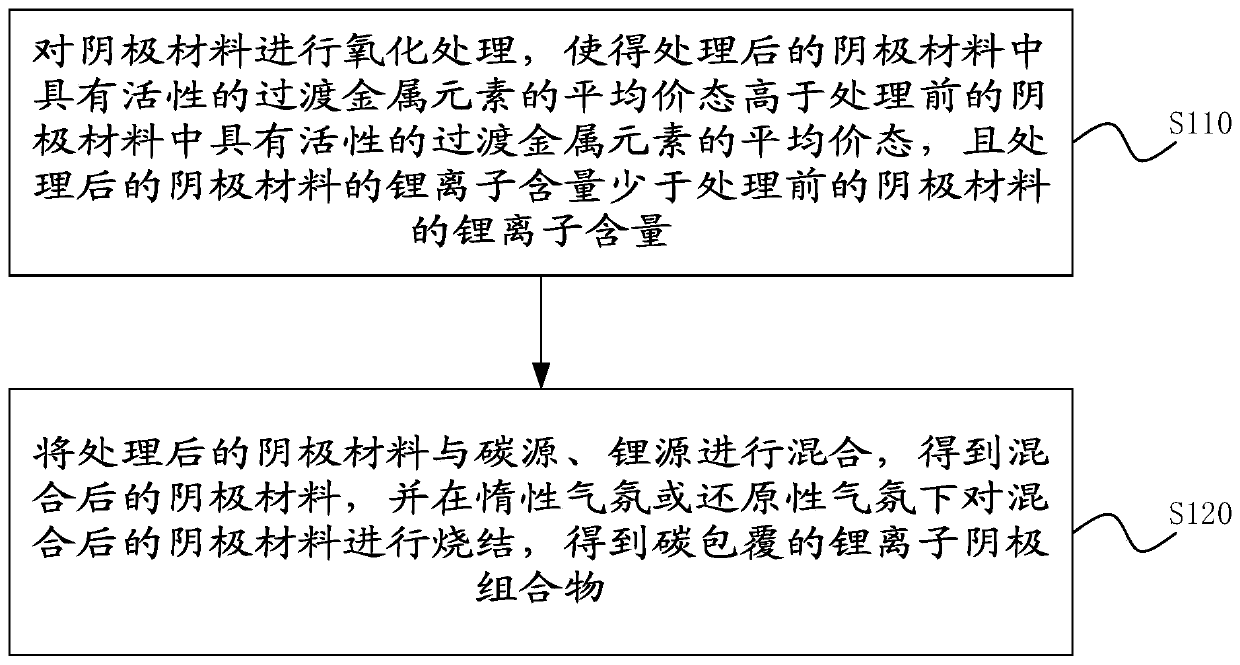

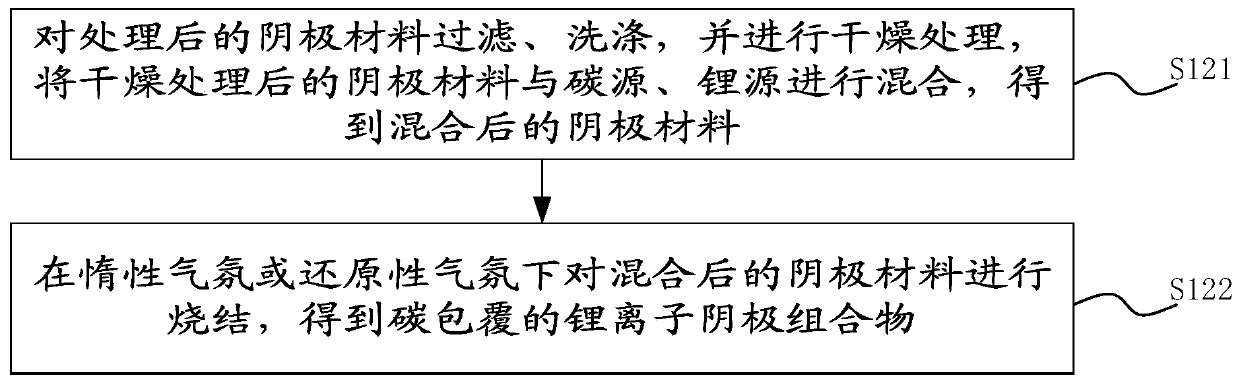

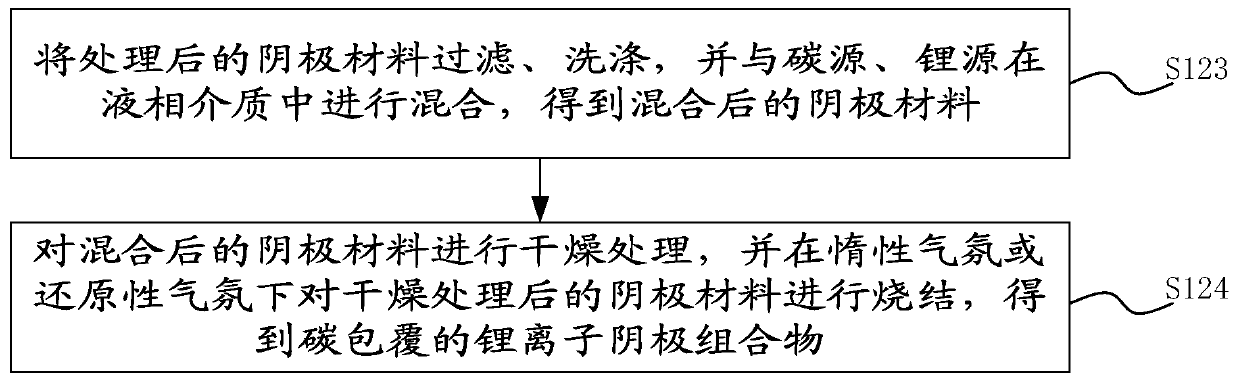

[0036] like figure 1 As shown, the embodiment of the present invention provides a preparation method of a cathode composition, comprising:

[0037] S110. Perform oxidation treatment on the cathode material, so that the average valence state of active transition metal elements in the cathode material after treatment is higher than the average valence state of active transition metal elements in the cathode material before treatment, and the cathode material after treatment has an average valence state of active transition metal elements. The lithium ion content of the material is less than the lithium ion content of the cathode material before treatment.

[0038] In some embodiments, the cathode material may be LiNi 1-x-y Co x Mn y O 2 , where 01-x-y Co x Al y O 2 , where 0x Mn 2-x O 4 Can also be used as cathode material, where 0≤x≤0.5. Alternatively, there is a cathode material that can use xLi 2 MnO 3 ·(1-x)LiXO 2 , where 00.6 Co 0.2 Mn 0.2 O 2 or Li 1-x Ni ...

Embodiment 1

[0082] Weigh 100 parts by mass of LiNi 0.6 Co 0.2 Mn 0.2 O 2 Cathode material, 6.15 parts by mass Na 2 S 2 O 8 (S 2 O 8 2- / SO 4 2- The standard reduction potential is 2.01V), added to 100 parts by mass of deionized water (solid content of 53%), stirred and reacted at normal temperature (25 ° C) for 6 hours, and then filtered, using 100 parts by mass of deionized water each time. water, and the filter cake was washed 3 times. It was then placed in a drying oven at 80°C for 12 hours. get Li 1-x Ni 0.6 Co 0.2 Mn 0.2 O 2 Sample (x is the proportion of lithium removed). Then according to Li per 100 parts by mass 1-x Ni 0.6 Co 0.2 Mn 0.2 O 2 Sample, weigh 7.0 parts by mass of sucrose and 2.3 parts by mass of LiOH·H 2 O, added to the ball mill for 4 hours, sieved, and the sieved material was packed in a corundum crucible, placed in a box furnace, sintered at 700°C for 4 hours under an inert atmosphere (nitrogen), cooled to room temperature, pulverized, Pass t...

Embodiment 2

[0097] Weigh 100 parts by mass of LiNi 0.8 Co 0.15 Al 0.05 O 2 Cathode material, 7.3 parts by mass KClO 4 (ClO 4- / ClO 3- The standard reduction potential is 1.2V), added to 50 parts by mass of deionized water (solid content of 68%), stirred and reacted at 40 ° C for 3 hours, and then filtered, using 100 parts by mass of deionized water each time, the The filter cake was washed 3 times. Take a filter cake sample, test the water content of the filter cake sample is about 8%, and then weigh 5.5 parts of asphalt and 4.7 parts of LiOH per 108.7 parts of the mass of the filter cake sample (corresponding to 100 parts of mass dewatering samples) ·H 2 O, was added to 40 parts by mass of ethanol (solid content was 73%), and the material was fully dispersed by ball milling to form a homogeneous mixture, dried in a vacuum drying oven at 60°C for 1 hour, pulverized and sieved. The sieve material is packed in a corundum crucible, placed in a box furnace, sintered at 650 ° C for 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com