An ion sensor for visually detecting thiocyanate based on color change, its preparation method and application

An ion sensor, thiocyanate technology, applied in the measurement of color/spectral properties, analysis by chemical reaction of materials, material analysis by observing the effect on chemical indicators, etc., can solve the problem of long detection time and complex preparation. Process detection methods, secondary pollution and other problems, to achieve the effects of low production cost, good anti-interference, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

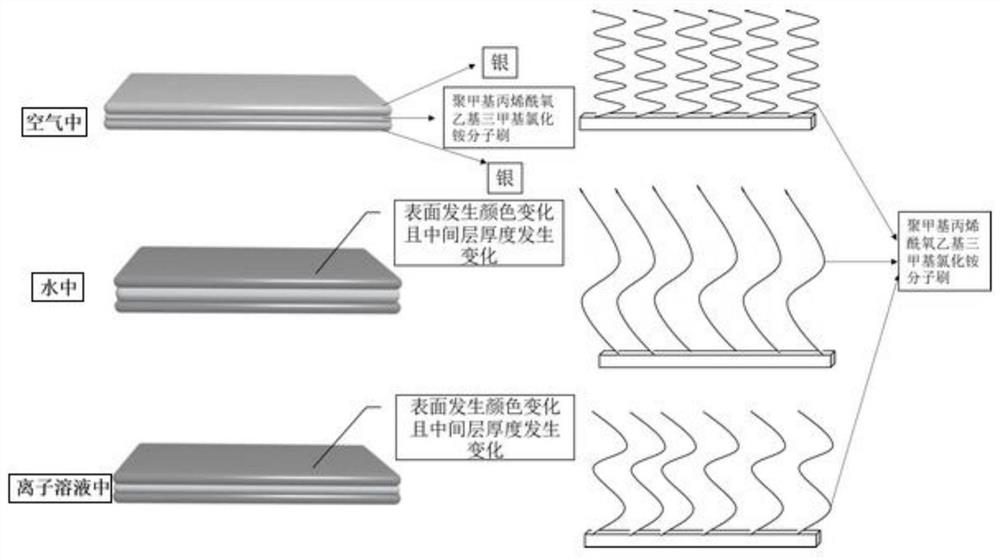

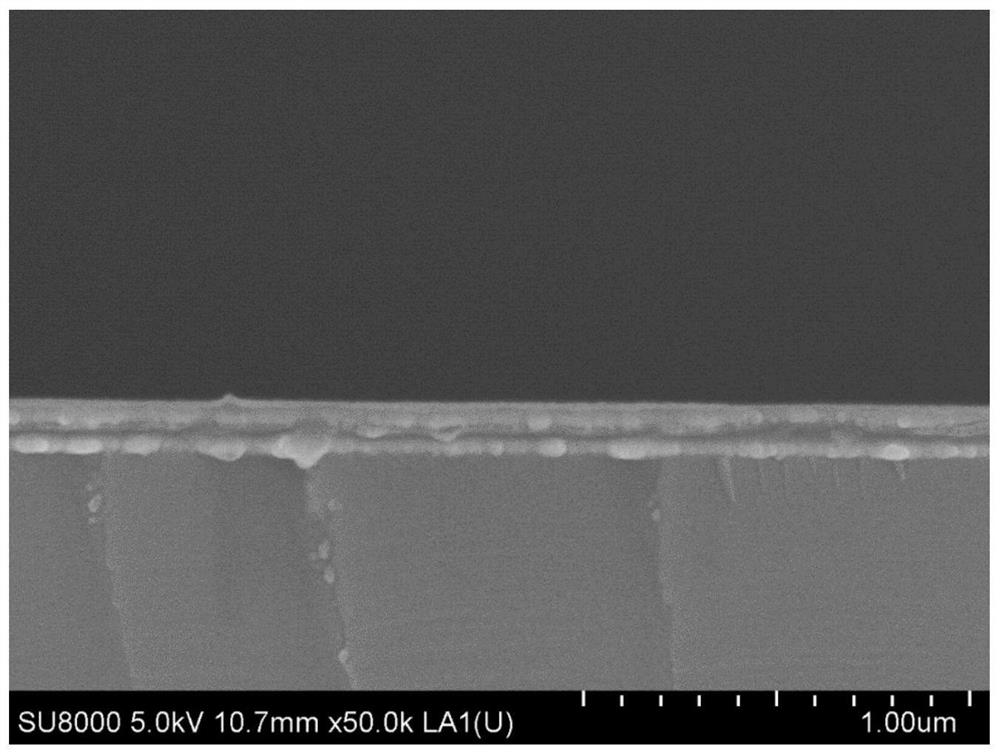

[0042] The preparation of the ion sensor based on the plasmon resonance metal layer 2 of the continuous metal layer is carried out according to the following process steps:

[0043] (1) A continuous silver layer (Ag layer) with a thickness of 24nm is evaporated on the glass substrate by vacuum evaporation method (Vacuum evaporator);

[0044] (2) grafting initiator 2-(2-bromoisobutyryloxy) undecyl mercaptan on the deposited silver layer;

[0045] (3) Add 1.0 g monomeric methacryloyloxyethyltrimethylammonium chloride solution (75 wt%) and 160 μL ligand pentamethyldiethylenetriamine to the test tube, then add methanol and deionized 3.7mL each of water, and argon for 30min;

[0046] (4) A copper plate is set on the glass substrate, and the glass substrate is put into a test tube with ligand and monomer, and the copper plate is used as a catalyst, and reacted for 20min at room temperature to form PMETAC molecules on the silver layer Brush and take it out; soak the glass substrate...

Embodiment 2

[0050] The preparation of the ion sensor based on the plasmon resonance metal layer 2 of the triangular structure is carried out according to the following process steps:

[0051] (1) A continuous silver layer (Ag layer) with a thickness of 30nm is deposited on the glass substrate by vacuum evaporation method (Vacuum evaporator);

[0052] (2) grafting initiator 2-(2-bromoisobutyryloxy) undecyl mercaptan on the deposited silver layer;

[0053] (3) Add 1.2 g monomeric methacryloyloxyethyltrimethylammonium chloride solution (75 wt%) and 160 μL ligand pentamethyldiethylenetriamine to the test tube, then add methanol and deionized Each 4mL of water, blown with argon for 30min;

[0054] (4) A copper plate is set on the glass substrate, the glass substrate is placed in a test tube with ligand and monomer, and the copper plate is used as a catalyst to react for 30min at room temperature to form PMETAC molecules on the silver layer Brush and take it out; soak the glass substrate in a...

Embodiment 3

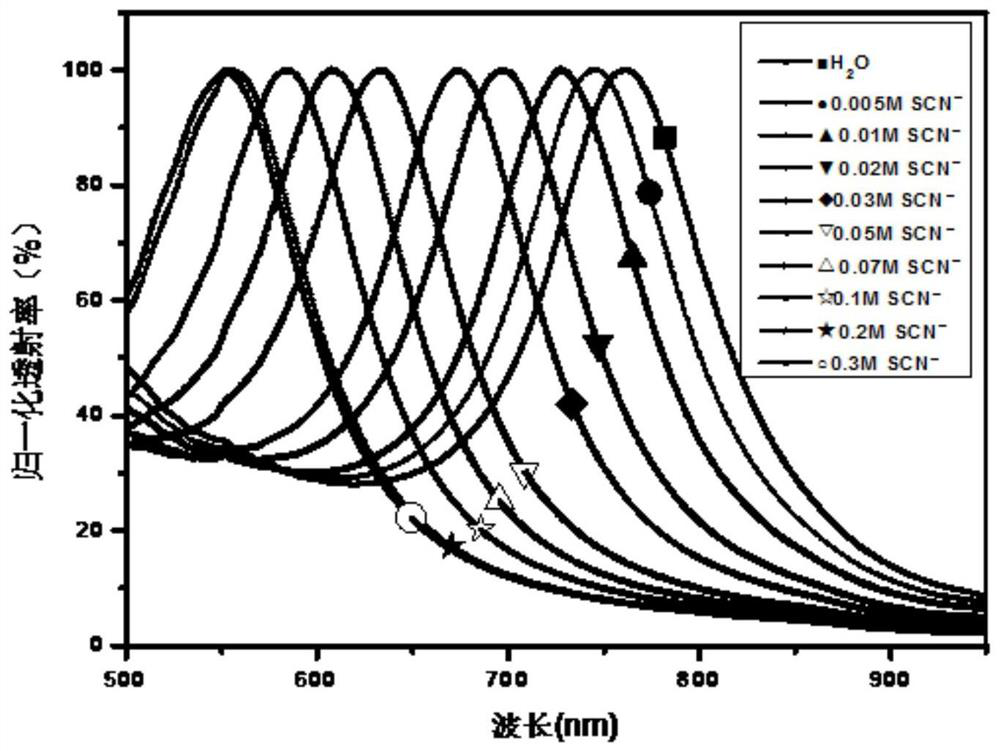

[0058] The test of the working transmission spectrogram of the ion sensor of embodiment 1 is carried out according to the following process steps:

[0059] (1) Prepare deionized water and configure different concentrations of thiocyanate solutions, the concentrations are 0.005M, 0.01M, 0.02M, 0.03M, 0.05M 0.07M, 0.1M, 0.2M, 0.3M.

[0060] (2) Soak the ion sensor in deionized water until the surface color of the ion sensor does not change, then take out the ion sensor.

[0061] (3) Soak the ion sensor soaked in deionized water in sequence in different concentrations of thiocyanate solution, the soaking sequence is from low concentration to high concentration; the soaking time is until the surface color of the ion sensor no longer changes.

[0062] (4) Use deionized water to gently rinse the ion sensor soaked in the thiocyanate solution, then soak the ion sensor in deionized water to make it swell to the maximum, and use a fiber optic spectrometer to test its transmission spectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com