Polyhedral oligomeric silsesquioxane-polyethylene glycol polymer solid electrolyte material and preparation method thereof

A technology of polysilsesquioxane and solid electrolyte, which is applied in solid electrolyte, non-aqueous electrolyte, secondary battery, etc. It can solve problems such as difficulties in the commercial field, hinder ion conduction, and poor processability, and achieve the purpose of inhibiting lithium branches. Crystal growth, good mechanical properties, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

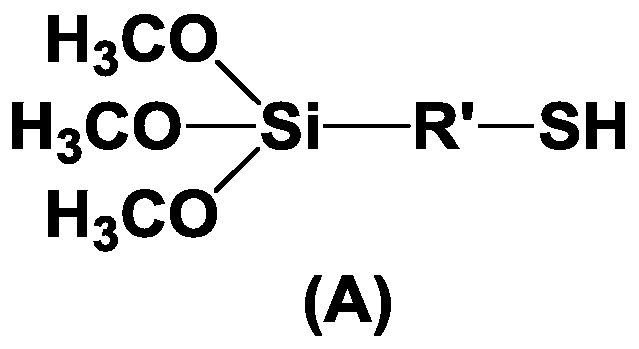

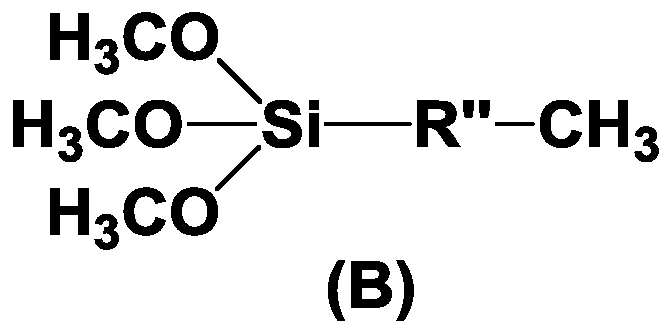

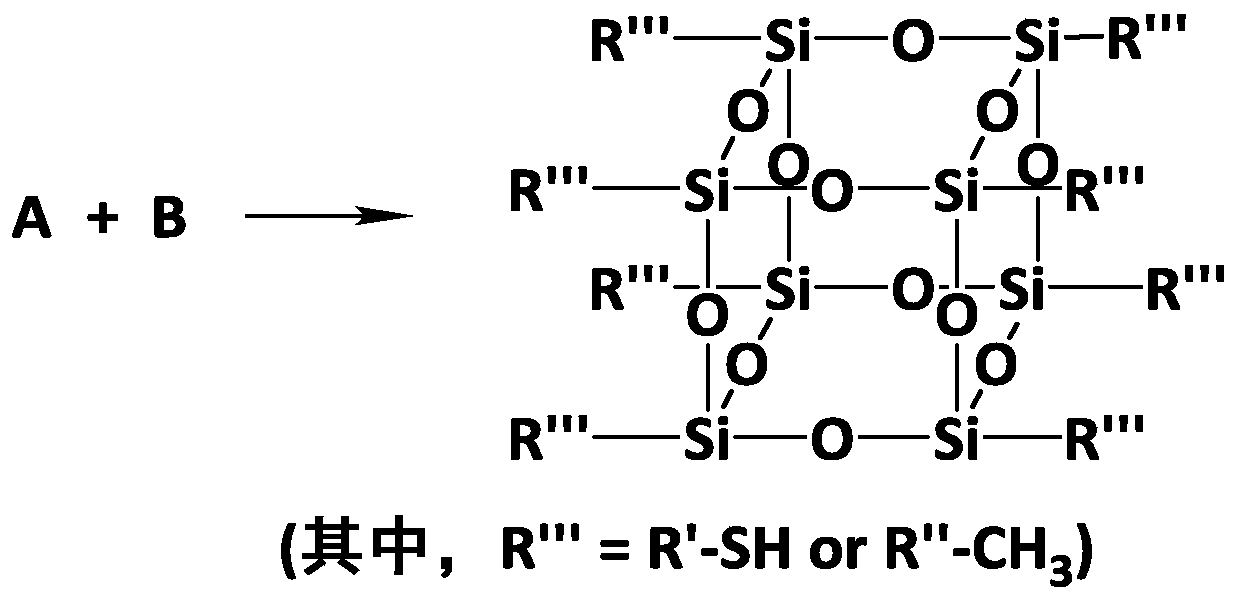

[0036] The preparation method of the cage polysilsesquioxane-polyethylene glycol polymer solid electrolyte material in the present invention is to graft the surface of the cage polysilsesquioxane with mercapto groups and polyethylene glycol end-capped with one-sided double bonds. The reaction raw materials including diol, add lithium salt and photoinitiator, configure according to the calculated ratio, stir evenly to obtain slurry, and cross-link and polymerize through ultraviolet light irradiation to obtain the polymer solid electrolyte material, which is used for lithium The preparation method of the cage type polysilsesquioxane-polyethylene glycol polymer solid electrolyte material of ion battery comprises the following steps:

[0037] (1) Dissolve 5~-60mL of trimethoxysilane and 10~100mL of concentrated hydrochloric acid with a mass fraction of 37% in 200~800mL of an organic solvent with a polarity of 5~7. Cage polysilsesquioxane grafted with mercapto groups;

[0038] (2)...

Embodiment 1

[0045] A cage polysilsesquioxane-polyethylene glycol polymer solid electrolyte material, specifically a cage polysilsesquioxane synthesized from (3-mercaptododecyl)trimethoxysilane and a polymer with a molecular weight of 200 Ethylene glycol methacrylate, the mass ratio of the feed is cage polysilsesquioxane:polyethylene glycol methacrylate is equal to 1:2; the added lithium salt is lithium bis-difluorosulfonimide, polyethylene The molar ratio of the ether oxygen group in the diol methacrylate to the lithium element in the lithium salt is 2:1; the photoinitiator benzophenone used, the amount of the photoinitiator added is the cage of the surface grafted mercapto group 0.1wt.% of the total mass of the blend of type polysilsesquioxane and polyethylene glycol methacrylate, and then polymerized by ultraviolet light irradiation.

[0046] The specific preparation method is:

[0047] Dissolve 20mL of (3-mercaptododecyl)trimethoxysilane and 20mL of concentrated hydrochloric acid with...

Embodiment 2

[0049] Cage polysilsesquioxane-polyethylene glycol polymer solid electrolyte material, specifically cage polysilsesquioxane synthesized from (3-mercaptopropyl) trimethoxysilane and polyethylene glycol with a molecular weight of 400 Alcohol methacrylate, the mass ratio of the feed is cage polysilsesquioxane: polyethylene glycol methacrylate is equal to 1:3; the added lithium salt is lithium bistrifluoromethanesulfonic acid imide, polyethylene The molar ratio of the ether oxygen group in the diol methacrylate and the lithium element in the lithium salt is 4:1; the photoinitiator propiophenone used, the photoinitiator addition amount is the cage poly The blend of silsesquioxane and polyethylene glycol methacrylate is 1 wt.% of the total mass, and then it is prepared by ultraviolet light irradiation polymerization.

[0050] The specific preparation method is:

[0051] Dissolve 10mL of (3-mercaptopropyl)trimethoxysilane and 40mL of concentrated hydrochloric acid with a mass fracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com