Preparation method of biomedical ordered porous as-cast zinc-based material

A biomedical, as-cast technology, applied in medical science, tissue regeneration, prostheses, etc., can solve the problems that the mechanical properties cannot be compared with as-cast metal products, the bionic structure cannot be realized, and the pore structure is difficult to quantitatively control, etc., and achieve excellent results. The effect of mechanical properties and service reliability, favorable for transportation and good structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the porous titanium-NaF composite preform specifically includes the following operations:

[0041] NaF slurry is composed of NaF particles, gelatin powder and supersaturated NaF aqueous solution, wherein NaF particles and gelatin are added in a mass ratio of 9:1. The mixture was placed in a stirrer and stirred at a speed of 55r / min for 30min to obtain NaF slurry;

[0042]As a preferred solution, the purity of the NaF particles is ≥99%, the particle size is 20-100 μm, and it will not cause corrosion to the zinc-based material when it is used as a preform material;

[0043] Use a uniaxial compression device to pressurize the NaF slurry to 4MPa to infiltrate the open-pore structure of porous titanium. The whole process should last at least 1 hour to ensure that the NaF slurry is completely filled;

[0044] The above composite material was heated up to 300°C at a rate of 3°C / min, sintered at a constant temperature for 5 hours, and then cooled to r...

Embodiment 1

[0058] This embodiment relates to a method for preparing an ordered porous cast zinc alloy for bone repair. The method specifically includes the following steps:

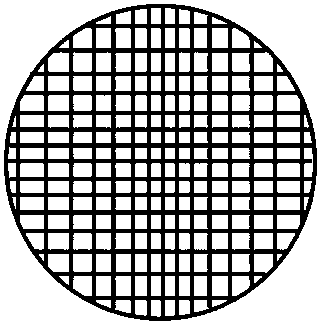

[0059] Step 1, design a porous material model with gradient pore structure by MIMICS, and its cross-sectional information is as follows figure 1 shown. Spherical titanium powder with a particle size of 35-45 μm is used as a raw material, and a porous titanium preform with a gradient pore structure is printed by SLM 250HL. During the preparation process, laser power: 20W; scanning speed: 300mm / s; scanning distance: 0.4-0.6mm ; Powder coating thickness: 10μm.

[0060] Step 2: Select NaF particles with stable chemical properties, gelatin and supersaturated NaF solution to stir slowly in a mixer for 30 minutes to obtain NaF slurry, use a compression device to fully infiltrate porous titanium, and obtain porous titanium after constant temperature sintering- NaF composite preform.

[0061] Step 3: Put the porous titani...

Embodiment 2

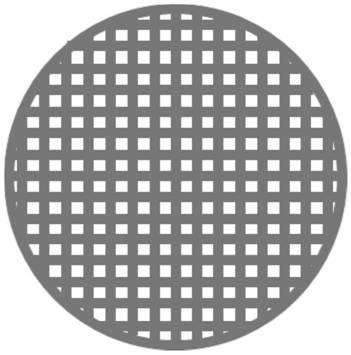

[0065] Step 1, use SLM 250HL to print a porous titanium preform with a pore size of 500 μm and a porosity ranging from 60% to 80%, such as figure 2 shown. Spherical titanium powder with a particle size of 30-40 μm is used as raw material, laser power during preparation: 35W; scanning speed: 500mm / s; scanning distance: 0.5mm; powder coating thickness: 20μm.

[0066] Step 2: Select chemically stable NaF particles, gelatin and supersaturated NaF aqueous solution to stir slowly in a mixer for 30 minutes to obtain NaF slurry, use a compression device to fully infiltrate porous titanium, and obtain porous titanium after constant temperature sintering- NaF composite preform.

[0067] Step 3: Put the porous titanium-NaF composite prefabricated body in a hydrogen fluoride vapor phase corrosion machine to remove the porous titanium, replace the acid mist every 24 hours, take out the prefabricated body after it is completely removed, dilute the residual material with water vapor, repea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com