Nitrogen-doped spherical porous carbon, its preparation method and its application

A technology of porous carbon and nitrogen doping, applied in the field of coal chemical industry, can solve the problem of low yield of carbon materials, and achieve the effect of wide sources, high nitrogen content, and high pelleting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

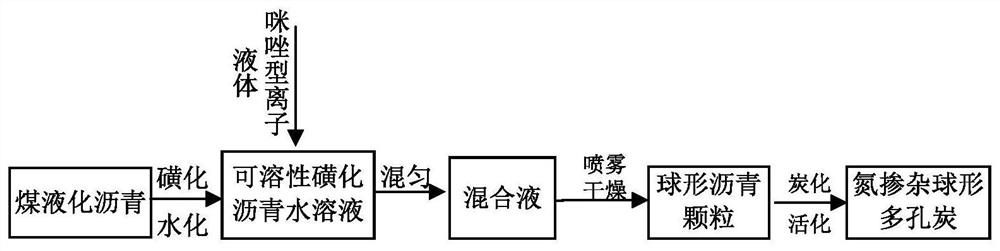

[0022] As described in the background art, in a conventional ionic liquid imidazolium cation Preparation of Nitrogen-doped carbon present low yield and low specific surface area of the porous carbon problems method. In order to solve the above problems, the present application provides a method for producing a nitrogen-doped spherical porous carbon, the production method comprising: a coal liquefaction process and bitumen sulfonated sequentially hydration treatment to obtain a soluble sulfonated asphalt; the soluble sulfo asphalt, water and a cationic ion-imidazol-liquid mixing to obtain a mixture, an imidazolium cation is the imidazolium cation ionic liquid bromine or chloride salt; the mixture was spray-dried to obtain spherical granules pitch; and in a nitrogen or inert gas under the protection of the spherical particles pitch carbonization and activation sequence to give spherical porous carbon doped with nitrogen.

[0023] The above preparation method, using relatively inex...

Embodiment 1

[0040] The 1500g particle diameter is less than 0.2 mm, and the ash is 0.001%, the softening point is 110 ° C, the coolification value of 50%, after 98% concentrated sulfonation, then dissolved by ion water, centrifugation is not soluble. The solid solids were obtained, and the soluble sulfonated asphalt was evaporated.

[0041] The soluble sulfonated asphalt was dissolved in a certain amount of deionized water, prepared a concentration of 20% sulfonated asphalt aqueous solution A. In the sulfonated asphalt aqueous solution A, 952 g of 1-acetonitrile-3-butylimazole cationic chloride ([CMBIM] CL) was added in accordance with mass ratio 1: 1 (ionic liquid: soluble sulfonated asphalt), and after stirring, dissolved, Get a mixed solution B.

[0042] By pump pressing, the mixed solution B is pressed into the spray drying tower in the feed temperature of 80 ° C, the feed pressure is 20 MPa, and the 528g spherical degree is collected from the bottom of the tower, and the particle size is...

Embodiment 2

[0045] The 1800g particle diameter is less than 0.2 mm, and the ash is 0.009%, the softening point is 131 ° C, the coal liquidification bitumen having a cocuplex value is 52.6%, and after 98% concentrated sulfonation, it is dissolved by ion water, and the centrifugation is dissolved. The solid solids were obtained, and the soluble sulfonated asphalt was evaporated.

[0046] The soluble sulfonated asphalt was dissolved in a certain amount of deionized water, prepared a sulfonated asphalt aqueous solution A having a concentration of 17%. In the sulfonated asphalt aqueous solution A, 345 g of 1-vinyl-3-acetonitrile primary immeolam cationic bromide salt ([CMVIM] BR) was added in accordance with mass ratio 1: 3 (ionic liquid: soluble sulfonated asphalt), and after stirring, dissolve, Get a mixed solution B.

[0047] By pumping pressure delivery, the mixed solution B is pressed into the spray drying tower in the feed temperature, the mixed solution B is pressed into the spray drying to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com