Convection assembly deposition method-based lead sulfide colloid quantum-dot solar cell and fabrication method thereof

A technology of colloidal quantum dots and solar cells, which is used in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of wasting quantum dot materials and complicated preparation processes, and achieves improved interface contact, improved morphology, and uniform film. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

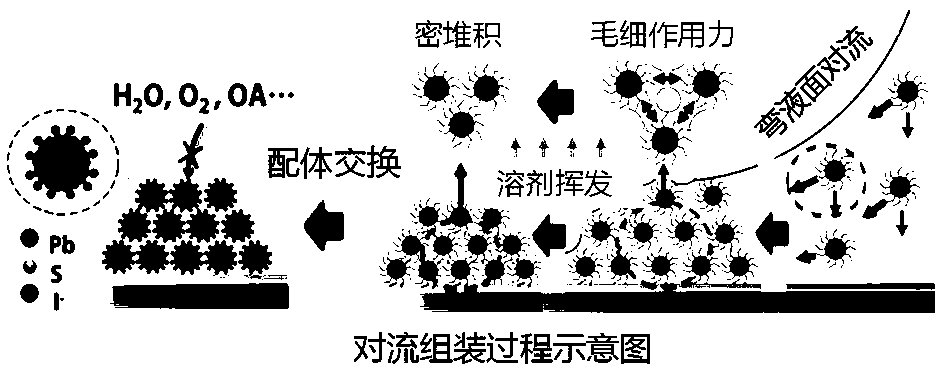

[0040] In this example, a colloidal quantum dot solar cell was prepared by a convective assembly method.

[0041] (1) Preparation of zinc oxide electron transport layer:

[0042] The ITO conductive glass was ultrasonically cleaned sequentially by deionized water, detergent, isopropanol, and acetone, and then the zinc oxide electron transport layer was prepared. The invention adopts two different types of zinc oxide electron transport layers, one of which is a planar structure electron transport layer based on zinc oxide nanocrystals, and the other is an ordered zinc oxide nanowire array electron transport layer.

[0043] a) Preparation of ZnO nanocrystals with planar structure:

[0044] Zinc acetate dihydrate (1.1 g) was transferred to a three-necked flask and dissolved in methanol solvent (76 ml), then the solution was heated to 60 °C under nitrogen atmosphere; potassium hydroxide (0.57 g) was dissolved in methanol (24 ml) and poured into a separatory funnel, then dropwise ...

Embodiment 2

[0056] In this embodiment, the photoelectric performance of the solar cell based on the zinc oxide nanocrystal planar structure electron transport layer is tested.

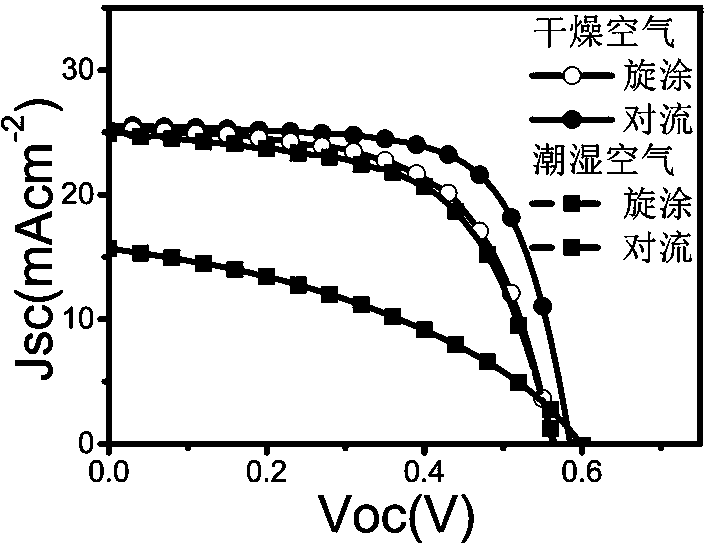

[0057]Under AM1.5 simulated light source (calibrated with NREL-certified standard silicon cells), at 100mW / cm 2 The power of the quantum dot solar cell prepared in Example 1 I-V The curves are compared and tested, and the results are as follows figure 2 and shown in Table 1.

[0058] See attached figure 2 , is measured under the AM1.5 solar simulator for the planar quantum dot device prepared by spin coating method and convective assembly deposition method in the present invention under dry or humid air conditions (relative humidity is about 10% or 60% respectively) The current-voltage curve diagram.

[0059] Table 1 shows the photovoltaic performance parameters of quantum dot solar cells obtained under different humidity conditions by convective assembly deposition method and spin coating method measured u...

Embodiment 3

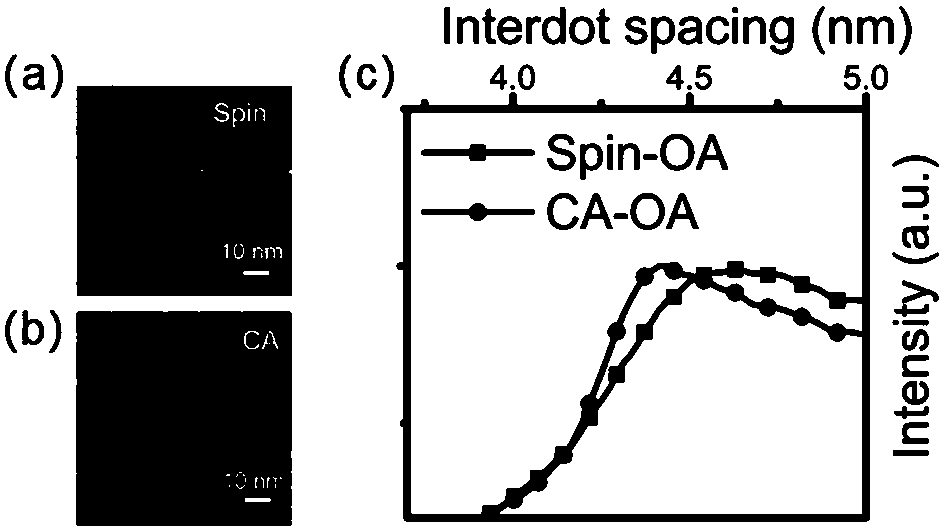

[0067] In this embodiment, a bulk heterojunction quantum dot solar cell based on a zinc oxide nanowire array is tested.

[0068] Under AM1.5 simulated light source, at 100mW / cm 2 The power of the quantum dot solar cell based on the zinc oxide nanowire array prepared in Example 1 I-V The curves are compared and tested, and the results are as follows Figure 5 and shown in Table 2.

[0069] See attached Figure 5 , is the current-voltage curve measured under the AM1.5 solar simulator for the preparation of bulk heterojunction quantum dot solar cells based on zinc oxide nanowire arrays in the present invention. From Figure 5 It can be seen from Figure a in the figure that the photoelectric conversion efficiency of the bulk heterojunction quantum dot solar cell device obtained by the convection assembly method in the method of the present invention is significantly higher than that of the quantum dot solar cell obtained by the spin coating method. Among them, the efficiency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com