A germanate infrared-transmitting glass and its preparation method

An infrared-transmitting, germanate technology, which is applied in glass manufacturing equipment, glass forming, manufacturing tools, etc., can solve the problems of difficult processing and forming, difficult forming of spinel, limited application range and service life, etc. The effect of market application prospect, good mask processing performance and excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

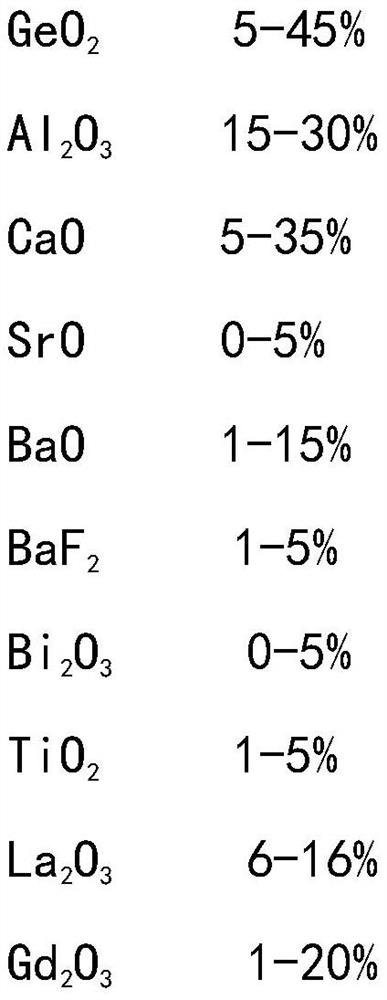

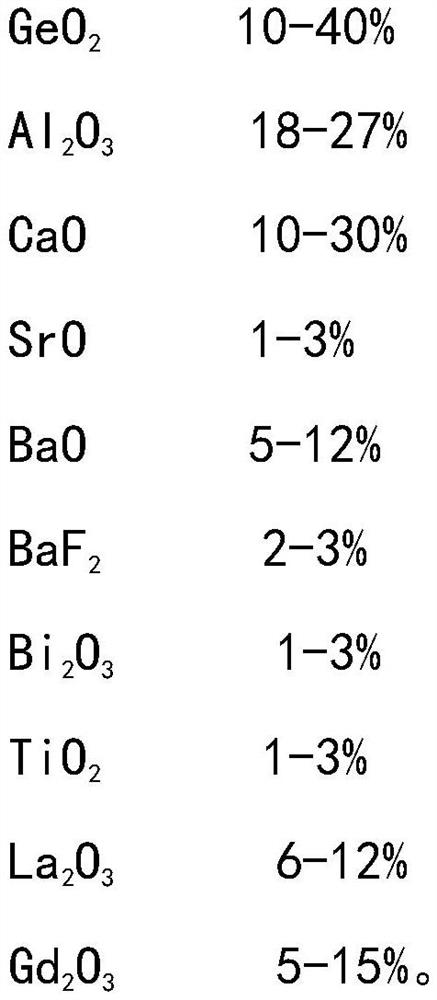

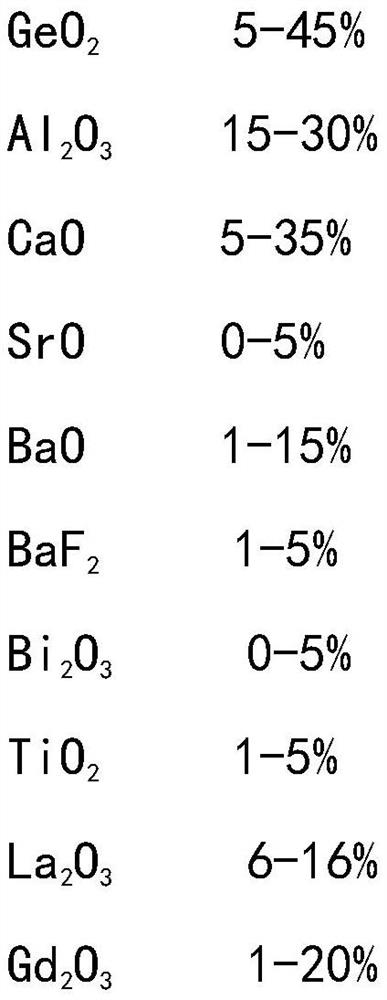

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a preparation method of germanate infrared-transmitting glass, comprising the following steps:

[0068] Step 1, glass batching: Before batching, the glass raw materials are subjected to high-temperature burning and dehydration treatment. Water vapor is the main component of the gas in the glass. It is based on [OH] - The form exists in the glass, which has an absorption band at 2.9 μm, and another gas CO in the glass 2 There is an absorption band at 2.7μm, strictly control the moisture and hydroxyl content of the raw materials, then mix the high-purity raw materials according to the designed components, and convert the corresponding raw material weights according to the weight percentage of each component, and then weigh each raw material , where Al 2 o 3 Introduced by alumina powder, without using hydroxide material, BaO is introduced by Ba(NO 3 ) 2 introduce;

[0069] Step 2, glass melting: Grind and mix the glass batch materia...

Embodiment 1

[0075]

[0076] First, select glass raw materials according to the glass composition of Example 1 in Table 1, raw material requirements, alumina powder (high purity, 150 μm sieve is less than 1%, 45 μm sieve is 30%), germanium oxide (400 μm sieve 10% or less, 63μm undersize is 10% or less), calcium carbonate (analytical pure, average particle size 250μm), strontium carbonate (analytical pure, purity ≥ 99.0%), barium nitrate (analytical pure, purity ≥ 99.0%) , barium fluoride (analytically pure, purity ≥ 99.0%), titanium oxide (analytical pure), bismuth oxide (analytical pure), lanthanum trioxide (5N), gadolinium oxide (5N), and the main raw materials in the glass raw materials Carry out high-temperature burning and dehydration treatment to reduce the moisture and hydroxyl content of glass raw materials, and strictly control the moisture and hydroxyl content of raw materials; then mix high-purity raw materials according to the glass chemical composition in Table 1, and then w...

Embodiment 2

[0078]

[0079] The actual composition of the glass refers to Example 2 in Table 1, uses the same raw materials and raw material requirements as in Example 1, and adopts a melting process system that melts at 1550 ° C for 2 hours and the same test conditions as in Example 1. Table 1 shows The basic performance of the sample. The transmittance of a glass sample with a thickness of 2 mm in the wavelength range of 1 μm to 5 μm is > 85%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com