Manganese pyrophosphate polyanionic lithium battery negative electrode material and preparation method thereof

A manganese pyrophosphate poly and anionic technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of unfavorable large-scale production, high equipment requirements, high energy consumption, and achieve single-phase and crystalline The effect of good performance, high product purity and high discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]The specific operation steps of the present embodiment are as follows: a concentration of 0.005mol / L manganese acetate ethanol solution is slowly added dropwise to a concentration of 0.0025mol / L pyrophosphoric acid ethanol solution; Stirring and reacting at a stirring speed of 60 rpm for 30 minutes; centrifuging the obtained precipitate, washing the obtained solid material with alcohol, and drying in an oven at 100° C. for 8 hours to obtain a manganese pyrophosphate polyanion lithium battery negative electrode material.

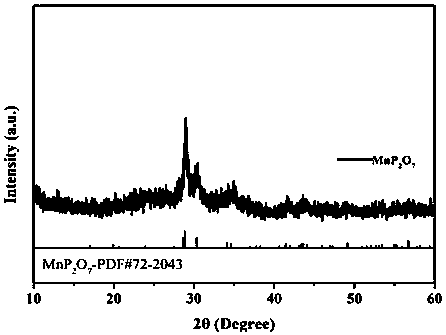

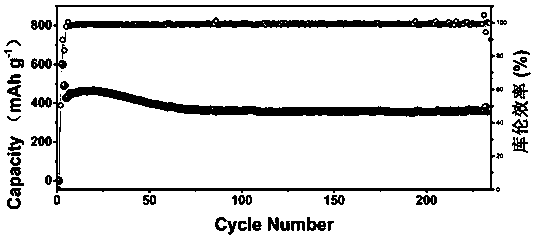

[0040] see figure 1 and figure 2 It can be seen that the manganese pyrophosphate polyanion lithium battery negative electrode material prepared in Example 1 has good single-phase and crystallinity, stable structure, and stable electrochemical performance.

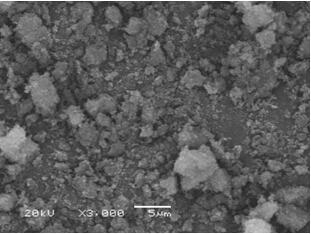

[0041] see image 3 , Figure 4 and Figure 5 , the manganese pyrophosphate polyanion lithium battery negative electrode material prepared in this example has a massive structure and is composed...

Embodiment 2

[0043] The specific operation steps of this embodiment are as follows: Slowly add the manganese acetate ethanol solution with a concentration of 0.02 mol / L into the ethanol solution with a concentration of 0.01 mol / L pyrophosphoric acid. Manganese acetate and pyrophosphoric acid were reacted with stirring at a stirring speed of 60 rpm for 30 minutes at a molar ratio of 1:1. The obtained mixed solution is centrifuged, washed with alcohol, and dried in an oven to obtain a block-shaped manganese pyrophosphate polyanion lithium battery negative electrode material.

[0044] see Figure 6-8 It can be seen that the manganese pyrophosphate polyanion lithium battery negative electrode material prepared in Example 2 has good single-phase and crystallinity, stable structure, and stable electrochemical performance.

[0045] Further, the obtained massive manganese pyrophosphate polyanion lithium battery negative electrode material was dried, that is, dried at 100°C for 8 hours, and then s...

Embodiment 3

[0047] The specific operation steps of this embodiment are as follows: Slowly add the manganese acetate ethanol solution with a concentration of 0.02 mol / L into the ethanol solution with a concentration of 0.01 mol / L pyrophosphoric acid. Then add 0.14191g graphene oxide (added by 5% of the mass of the product), manganese acetate and pyrophosphoric acid in a molar ratio of 1:1, stir and react at a stirring speed of 60 rpm for 30 minutes, and carry out the mixed solution obtained centrifuging, washing with alcohol, and drying in an oven to obtain a block-shaped manganese pyrophosphate polyanion lithium battery negative electrode material.

[0048] see Figures 9 to 11 It can be seen that the manganese pyrophosphate polyanion lithium battery negative electrode material prepared in Example 3 has good single-phase and crystallinity, stable structure, and stable electrochemical performance.

[0049] Further, the obtained massive manganese pyrophosphate polyanion lithium battery neg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com