Wettable cathode material for aluminum electrolytic cell as well as preparation method and application thereof

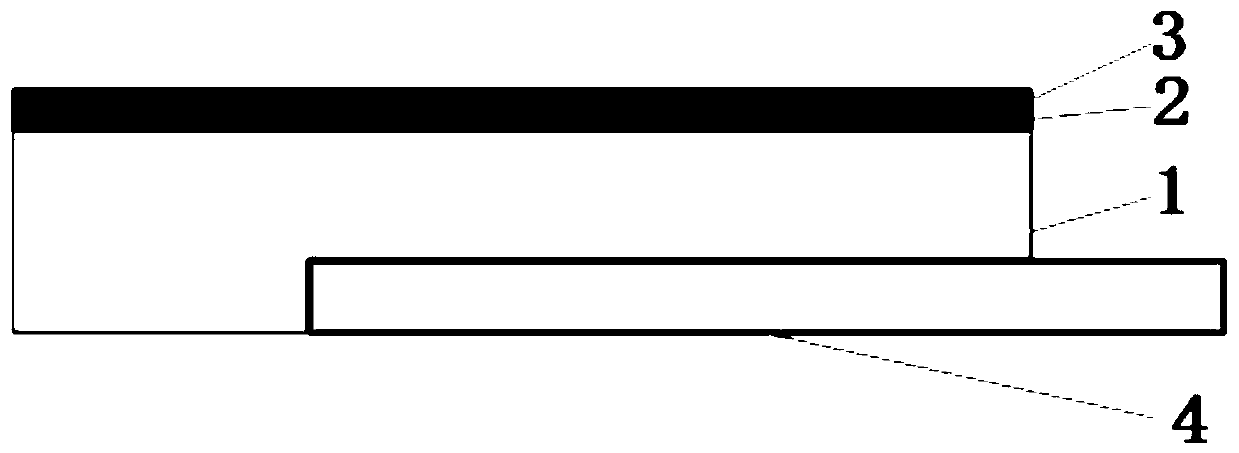

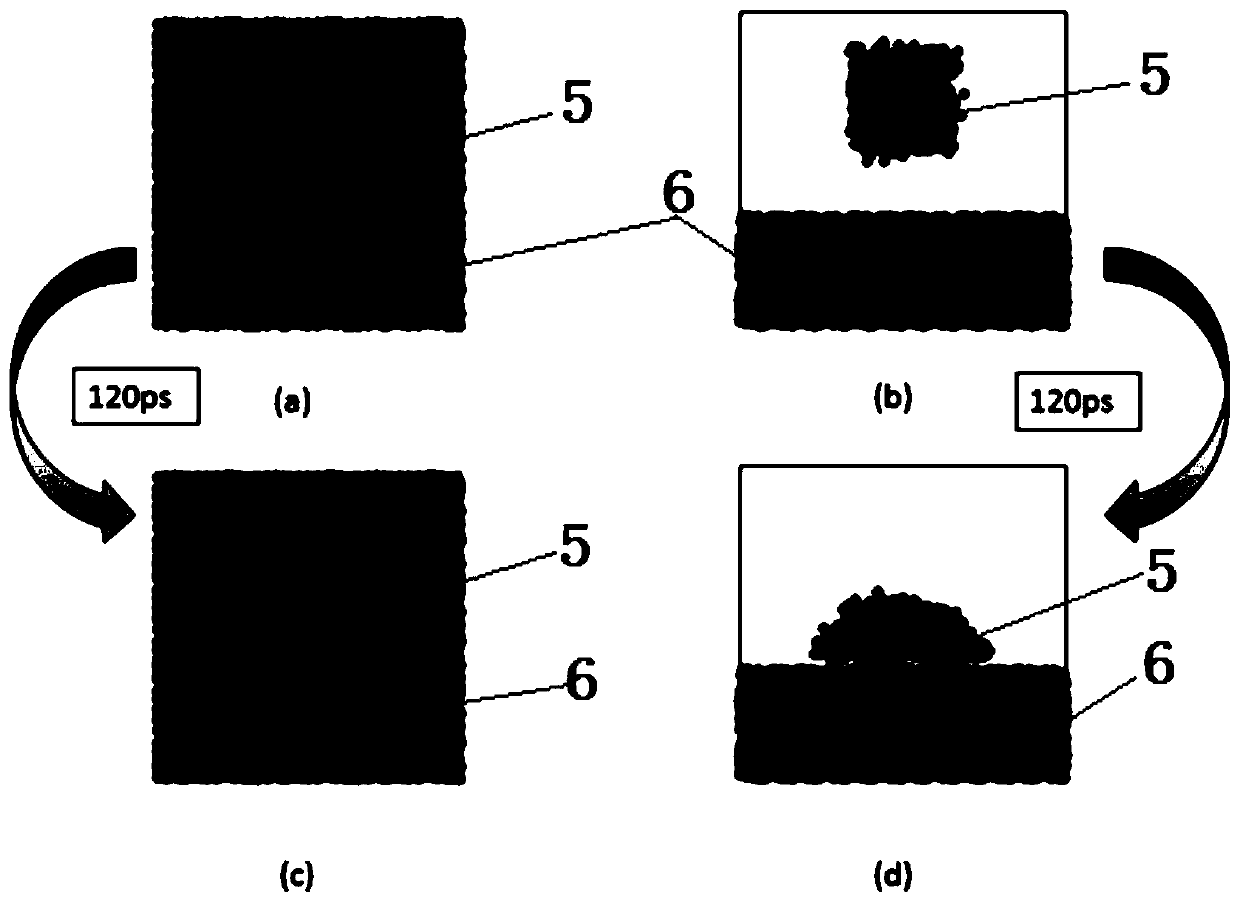

A technology of aluminum electrolytic cells and cathode materials, which is applied to the device for coating liquid on the surface, the pretreatment surface, and coatings, etc., which can solve the problems of uneven coating thickness, shedding, and the reduction of cathode corrosion resistance, and achieve strong Erosion resistance of high temperature molten salt, high tensile mechanical strength, smooth surface without cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation process of wettable cathode material for aluminum electrolytic cell is as follows:

[0044] A. Prepare materials according to the following ingredients: 30g of graphene powder, 35g of epoxy resin, and 35g of ethylene glycol, to obtain raw materials with a total mass of 100g, put ethylene glycol into a liquid container, add epoxy resin, and stir evenly to obtain a liquid Material: Slowly pour the graphene powder into the liquid material, and stir while adding the graphene powder until the graphene powder and the liquid material are evenly mixed to obtain a glue;

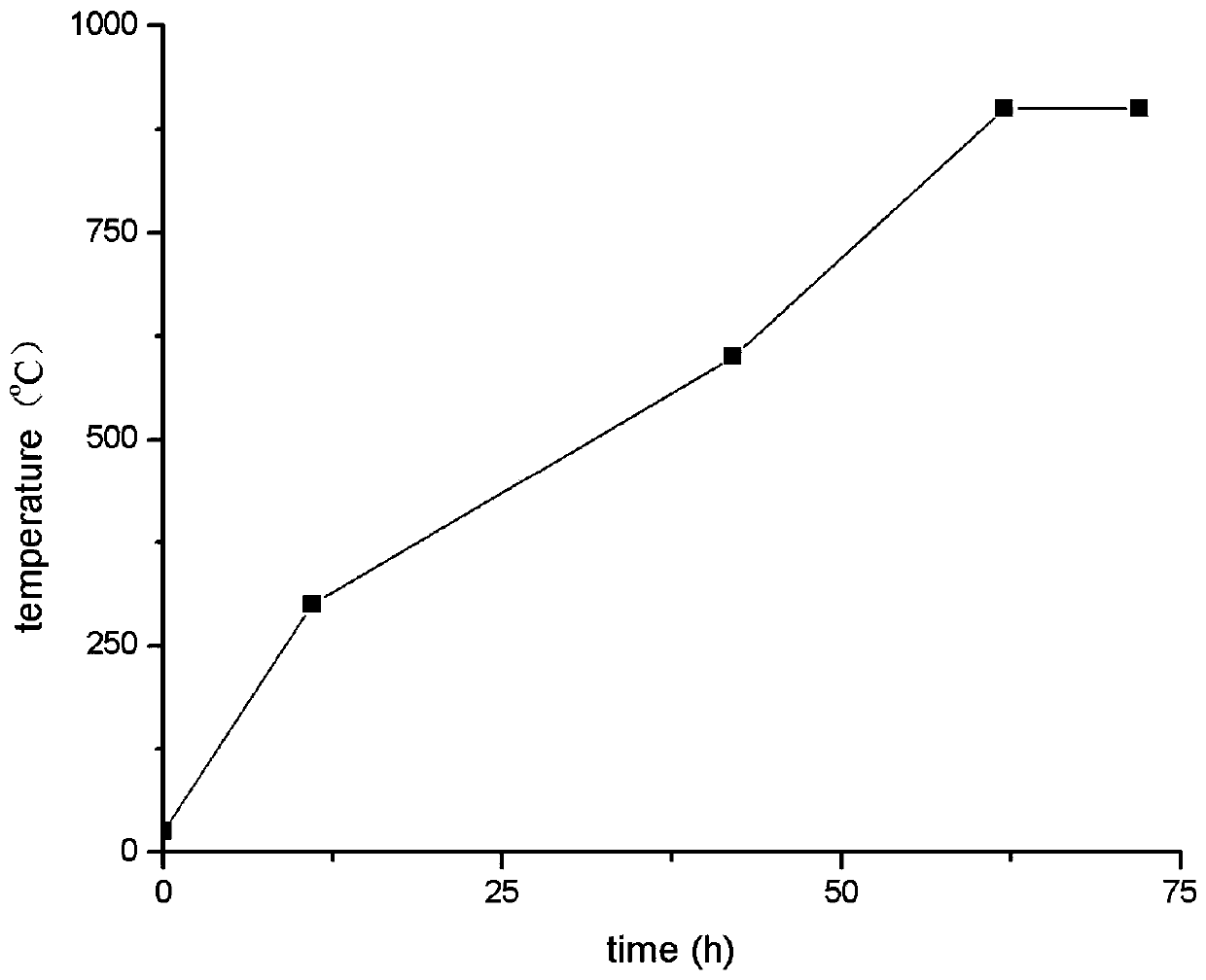

[0045] B. The glue solution obtained in step A is coated with a layer of glue solution film with a thickness of 25um on the carbon block by spin coating, and then cured at room temperature for 12 hours. Under an inert atmosphere (argon), use such as figure 2 According to the carbonization heating curve shown, heat treatment is carried out, and then after cooling at room temperature, a layer of ...

Embodiment 2

[0048] The preparation process of wettable cathode material for aluminum electrolytic cell is as follows:

[0049] A, prepare materials according to the following ingredients: 35g of graphene powder, 30g of epoxy resin, 35g of ethylene glycol, to obtain a raw material with a total mass of 100g, put ethylene glycol into a liquid container, add epoxy resin, stir evenly, and obtain a liquid Material: Slowly pour the graphene powder into the liquid material, and stir while adding the graphene powder until the graphene powder and the liquid material are evenly mixed to obtain a glue;

[0050] B, the glue solution that step A is obtained is plated the glue solution film that one deck thickness is 22um on the charcoal block by spin coating method, then carry out 12 hours room temperature curing, then adopt such as figure 2 Carry out carbonization treatment according to the carbonization heating system shown. After cooling at room temperature, a layer of glue solution film with a thi...

Embodiment 3

[0052] The preparation process of wettable cathode material for aluminum electrolytic cell is as follows:

[0053] A. Prepare materials according to the following ingredients: 40g of graphene powder, 30g of epoxy resin, and 30g of ethylene glycol to obtain a raw material with a total mass of 100g, put ethylene glycol into a liquid container, add epoxy resin, and stir evenly to obtain a liquid Material: Slowly pour the graphene powder into the liquid material, and stir while adding the graphene powder until the graphene powder and the liquid material are evenly mixed to obtain a glue;

[0054] B, the glue solution obtained in step A adopts the spin coating method to plate a layer of glue solution film with a thickness of 20um on the carbon block substrate, and then carry out 12 hours of room temperature curing. Under an inert atmosphere, use such as figure 2 Carry out carbonization treatment according to the carbonization heating system shown, and after cooling at room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com