honeycomb porphyrin cop and g-c 3 no 4 Synthesis of Composite Materials and Its Application in Photocatalytic Degradation of Dyes

A composite material, g-c3n4 technology, applied in the field of new inorganic composite materials, can solve the problems of limitation, low specific surface area, and high synthesis cost of porphyrin COP, and achieve the effects of low cost, increased absorption range, and new synthesis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] g-C 3 N 4 Preparation of melamine: put 15g of melamine in an alumina crucible, cover the lid, put it into a muffle furnace, heat at a rate of 10°C / min, and heat for 1 hour at 550°C under the protection of nitrogen to obtain a light yellow powder g-C 3 N 4 7.8g.

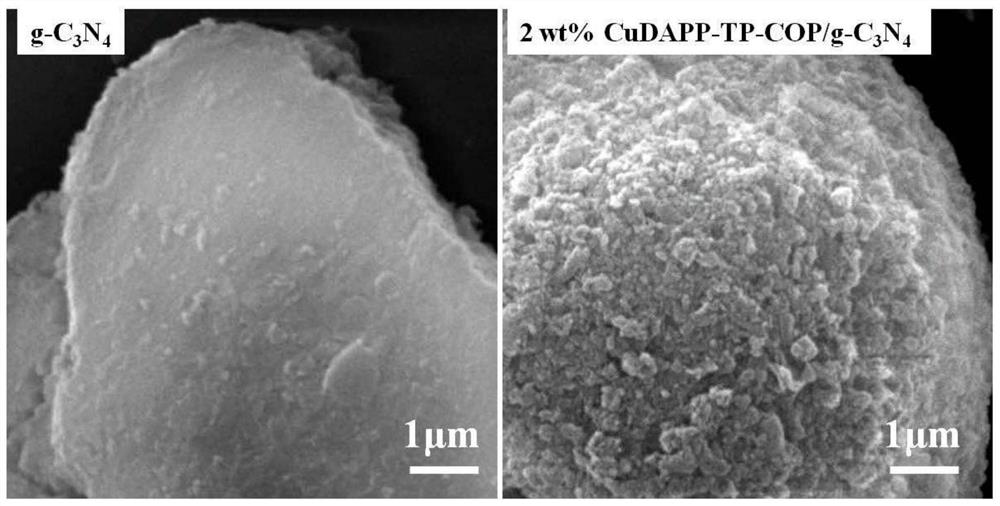

[0032] 2wt% CuDAPP-TP-COP / g-C 3 N 4 Preparation: Weigh g-C 3 N 4 200mg, trialdehyde pyroglucinol 2mg, then add two drops of o-dichlorobenzene and n-butanol (volume ratio 1:1) mixed solution and 1 drop of 6M acetic acid solution, grind for 0.5h, then add 4mg 5,15-di( 4-aminobenzene)-10,20-diphenylporphyrin copper, then add two drops of a mixed solution of o-dichlorobenzene and n-butanol (1:1) and 1 drop of 6M acetic acid solution, continue grinding for 2 hours, and finally use three Chloromethane, methanol wash, filter and dry to get 2wt% CuDAPP-TP-COP / g-C 3 N 4 ; Prepare 1wt% CuDAPP-TP-COP / g-C by the same method 3 N 4 , 3wt% CuDAPP-TP-COP / g-C 3 N 4 , 4wt% CuDAPP-TP-COP / g-C 3 N 4 and CuDAPP-TP-...

Embodiment 2

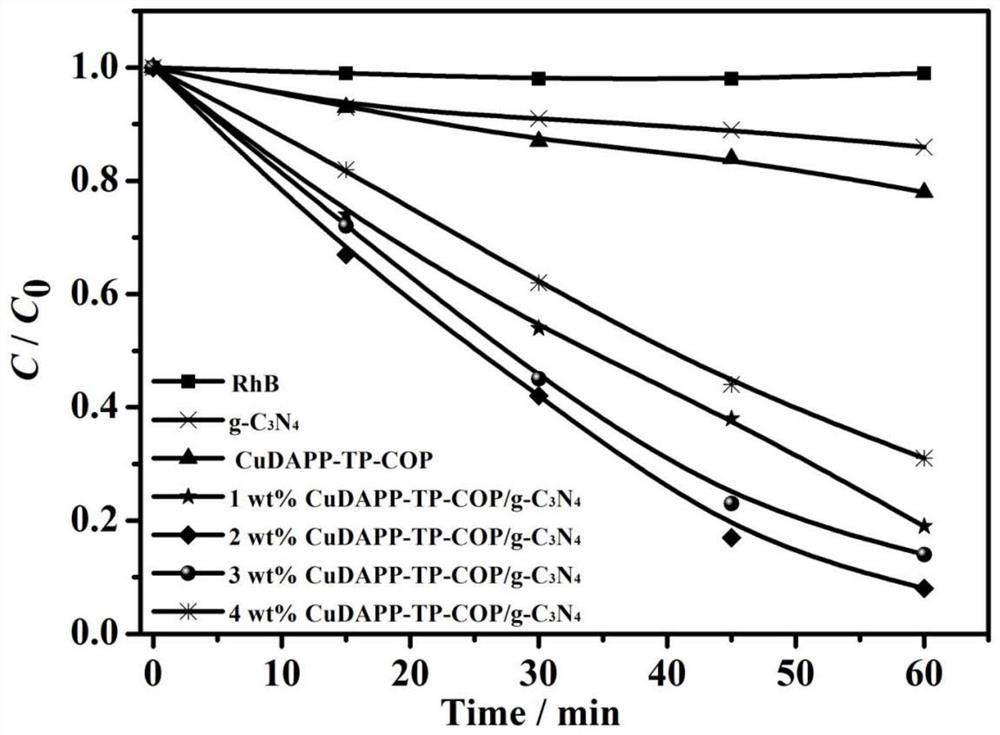

[0035] Photocatalytic degradation experiment: In order to further explore the synthesis of CuDAPP-TP-COP / g-C 3 N 4 The performance of the composite material, a series of experiments were designed to verify the efficiency of its catalytic degradation of Rhodamine B.

[0036] Take 20mg catalyst (CuDAPP-TP-COP, g-C 3 N 4 , 1wt% CuDAPP-TP-COP / g-C 3 N 4 , 2wt% CuDAPP-TP-COP / g-C 3 N 4 , 3wt% CuDAPP-TP-COP / g-C 3 N 4 , 4wt% CuDAPP-TP-COP / g-C 3 N 4 ), then add 50mL 10mg / L RhB aqueous solution. After stirring for 1 hour without light to reach adsorption equilibrium, the RhB aqueous solution was irradiated with a 400nm filter xenon lamp light source, and the reaction solution was taken every 15 minutes, centrifuged, and the supernatant was taken to measure its absorbance.

[0037] Such as figure 2 Shown, combined with 1%, 2%, 3%, 4% CuDAPP-TP-COP / g-C 3 N 4 Material degradability and pure g-C 3 N 4 Compared with significantly improved, pure g-C 3 N 4 The degradation eff...

Embodiment 3

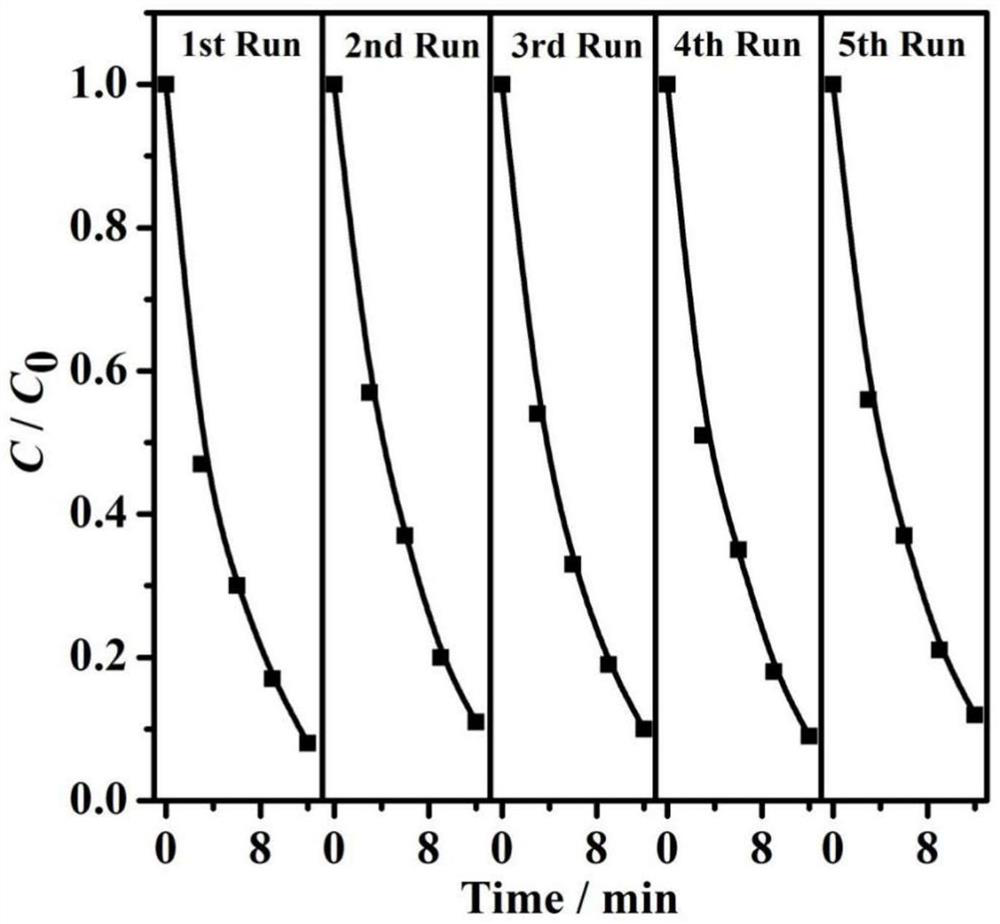

[0039] pH condition screening: take 20mg 2wt% CuDAPP-TP-COP / g-C 3 N 4 , then add 50mL (10 mg / L) RhB aqueous solution, adjust the pH of the solution to 3, 5, 7 with 1mol / L hydrochloric acid solution, and ultrasonically ensure that the catalyst is completely dispersed. After dark adsorption for 1 hour to reach adsorption equilibrium, the RhB aqueous solution was irradiated with a 400nm filter xenon lamp light source, and the reaction solution was taken every 3 minutes, centrifuged, and the supernatant was taken to measure its absorbance. 2wt% CuDAPP-TP-COP / g-C in pH 5 solution 3 N 4 It showed the best catalytic performance, and the catalytic efficiency reached 100% in 12 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com