Binary-doping single-crystal ternary positive electrode material and preparation method thereof

A positive electrode material, binary doping technology, applied in the field of lithium-ion batteries, can solve the problems of battery cycle stability and safety to be improved, the inability to form single crystal ternary positive electrode materials, capacity and stability, etc., reaching a high level Stable, no capacity decay, less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

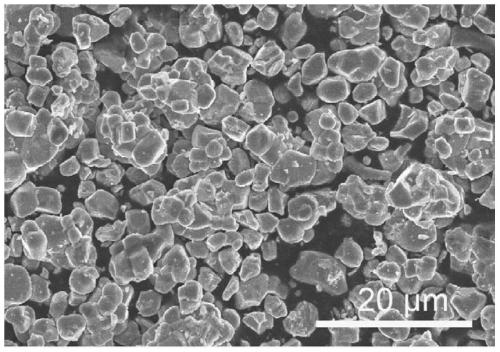

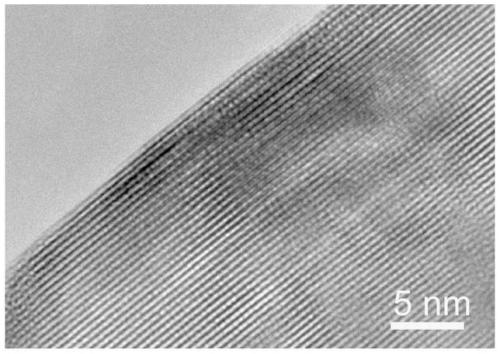

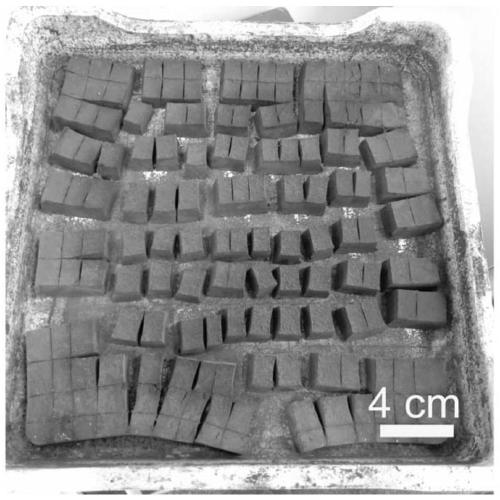

[0039] Ni 0.8 co 0.1 mn 0.1 (OH) 2 The ternary positive electrode precursor, the first dopant aluminum acetate, and the second dopant titanium oxalate are mixed uniformly by a ball mill, and the solid powder is obtained by spray drying, wherein the molar ratio of the ternary positive electrode precursor, aluminum acetate, and titanium oxalate is 1 :0.02:0.001; the above-mentioned obtained solid powder, lithium hydroxide monohydrate and the lithium salt mixture of lithium carbonate, and the first solid additive sodium citrate are mixed uniformly and then sintered, wherein the lithium mole of lithium hydroxide monohydrate accounts for the mixture The molar ratio of lithium is 0.95, and the molar ratio of lithium salt, ternary positive electrode precursor and first solid additive is 1.03:1:0.3. The sintering procedure is specifically to place the mixture in an oxygen atmosphere furnace with an oxygen volume ratio of 95%, at 5 °C min -1 The heating rate is increased to 500°C a...

Embodiment 2

[0041] The binary doped single crystal ternary lithium battery positive electrode material was prepared according to the same operating conditions and steps as in Example 1, except that the first dopant was replaced by aluminum hydroxide.

Embodiment 3

[0043] The binary doped single crystal ternary lithium battery cathode material was prepared according to the same operating conditions and steps as in Example 1, except that the first dopant was replaced by magnesium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com