Early strengthening polycarboxylate superplasticizer for C30 concrete

A technology of polycarboxylic acid and water reducing agent, which is applied in the field of building materials and concrete admixtures, can solve problems such as troubles and losses, and achieve the effects of not easy to fall off, good workability, and good water reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

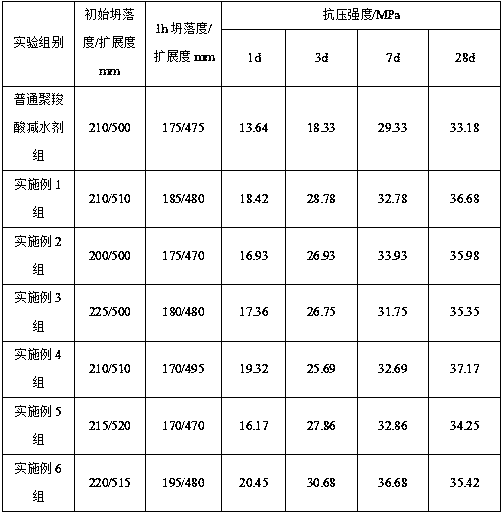

Examples

Embodiment 1

[0038] C30 early-strength polycarboxylate superplasticizer for concrete, comprising the following components in parts by weight:

[0039]342 parts of 4000 molecular weight polyether macromonomer, 24 parts of acrylic acid, 8 parts of N-methylmaleimide, 5 parts of 27.5% industrial grade hydrogen peroxide, 4.5 parts of sodium vinyl sulfonate, and a mass ratio of 3:1 2.5 parts of acryloyloxyethyl phosphate and ethylene glycol methacrylate phosphate, 0.4 parts of sodium dithionite, 1.4 parts of thioglycolic acid, 12 parts of sodium hydroxide,

[0040] The remainder is water, the total mass is 1000 parts, the mass fraction of the finished product after preparation is 40%, and the acid-ether ratio is 3.9.

[0041] The specific preparation process of early-strength polycarboxylate superplasticizer for C30 concrete is as follows:

[0042] 1. Add 342 parts of 4000 molecular weight polyoxyethylene amine ether and 4000 molecular weight allyl polyoxyethylene ether in a mass ratio of 1:6, ...

Embodiment 2

[0047] C30 early-strength polycarboxylate superplasticizer for concrete, comprising the following components in parts by weight:

[0048] 350 parts of 4000 molecular weight polyether macromonomer, 27 parts of acrylic acid, 4 parts of N-ethylmaleimide, 4.5 parts of 27.5% industrial grade hydrogen peroxide, 3.5 parts of sodium acrylsulfonate, methacryloyloxyethyl phosphoric acid 2 parts of esters, 0.4 parts of sodium formaldehyde sulfoxylate, 1.6 parts of the composition of mercaptoacetic acid and mercaptopropionic acid with a mass ratio of 1:2, 12 parts of potassium hydroxide, the remainder is water, and the total mass is 1000 parts, prepared The mass fraction of the finished product is 40%, and the acid-ether ratio is 4.3.

[0049] The specific preparation process of early-strength polycarboxylate superplasticizer for C30 concrete is as follows:

[0050] 1. A mixture of 350 parts of 4000 molecular weight polyoxyethylene amine ether and 4000 molecular weight methallyl polyoxye...

Embodiment 3

[0055] C30 early-strength polycarboxylate superplasticizer for concrete, comprising the following components in parts by weight:

[0056] 346 parts of 4200 molecular weight polyether macromonomer, 24 parts of acrylic acid, 5 parts of 1,4-divinyl-2-azepanone, 4 parts of 27.5% industrial grade hydrogen peroxide, 6 parts of sodium methacrylate, and 3 parts of diol methacrylate phosphate, 0.5 part of ascorbic acid, 1.6 parts of mercaptoethanol, 7 parts of sodium carbonate, the rest is water, the total mass is 1000 parts, the mass fraction of the finished product after preparation is 40%, and the acid-ether ratio is 4.0 .

[0057] The specific preparation process of early-strength polycarboxylate superplasticizer for C30 concrete is as follows:

[0058] 1. A mixture of 346 parts of 4200 molecular weight polyoxyethylene amine ether and 4200 molecular weight isopentenol polyoxyethylene ether in a mass ratio of 1:6, 5 parts of 1,4-divinyl-2-azepane Add ketone and 170 parts of water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com