A kind of transition metal chalcogenide thin layer material and its preparation method and application

A technology of transition metal chalcogenide and thin-layer materials, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc. Good uniformity and other problems, to achieve the effect of good shape, simple and easy preparation process, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

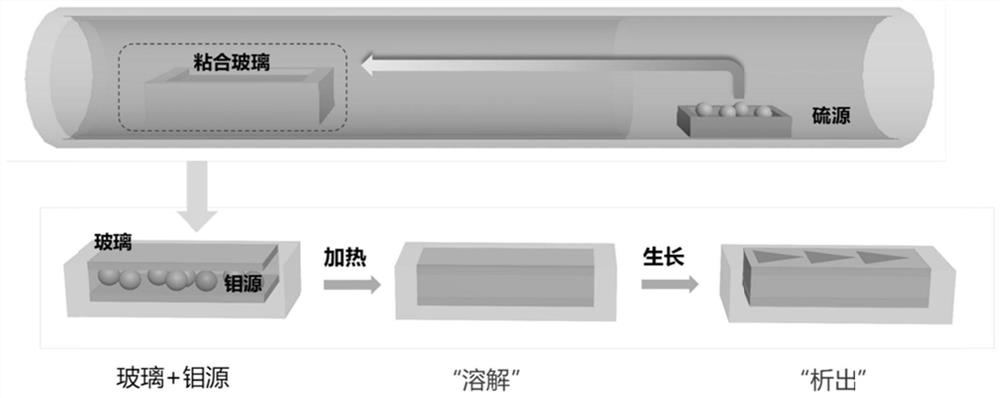

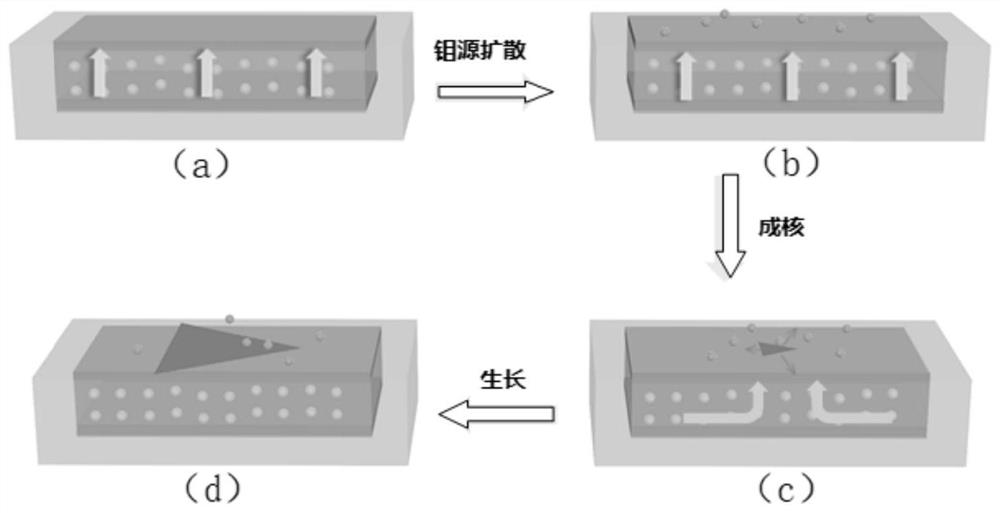

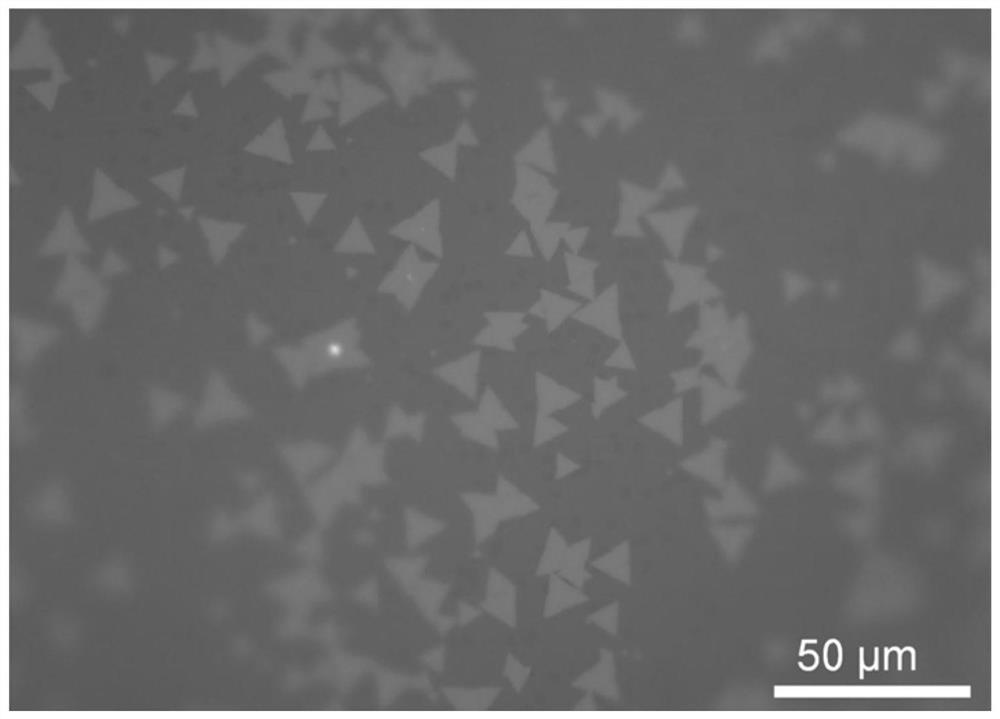

[0047] This embodiment provides a large-area, highly uniform molybdenum disulfide thin-layer material and its preparation method. The schematic diagram of the preparation method is as follows figure 1 As shown, it specifically includes the following steps:

[0048] (1) Spread 0.94mg of sodium molybdate (molybdenum source) evenly on the surface of the soda-lime glass substrate whose length, width and thickness are 25mm×10mm×2mm. 1. A soda-lime glass substrate with a thickness of 0.15mm; heat treatment was carried out in a muffle furnace at 700°C for 30 minutes, and the heating rate was 20°C / min; after heat treatment, the two glass substrates were fused and bonded together;

[0049] (2) The glass substrate bonded in step (1) is placed in the second heating zone of the tube furnace as the substrate and the molybdenum source simultaneously, and the sulfur powder (sulfur source) is placed in the upstream of the second heating zone in the tube furnace In the first heating zone, the...

Embodiment 2

[0054] This embodiment provides a large-area, highly uniform molybdenum disulfide thin-layer material and a preparation method thereof, the preparation method comprising the following steps:

[0055] (1) Spread 1.88mg of sodium molybdate evenly on the surface of a potassium glass substrate with a length, width, and thickness of 5mm×10mm×3mm. Soda-lime glass substrate; heat treatment in a muffle furnace at 720°C for 30 minutes, with a heating rate of 30°C / min; after heat treatment, the two glass substrates are fused and bonded together;

[0056] (2) The glass substrate bonded in step (1) is placed in the second heating zone of the tube furnace as the substrate and the molybdenum source simultaneously, and the sulfur powder (sulfur source) is placed in the upstream of the second heating zone in the tube furnace The first heating zone, the quality of sulfur powder used is 300mg;

[0057] (3) In the tube furnace described in step (2), feed argon gas at a rate of 80 mL / min, and ma...

Embodiment 3

[0060] This embodiment provides a large-area, highly uniform tungsten disulfide thin layer material and its preparation method, the preparation method comprising the following steps:

[0061] (1) Spread 0.94mg of sodium tungstate (tungsten source) evenly on the surface of a soda-lime glass substrate with a length, width, and thickness of 25mm×10mm×2mm. 1. A soda-lime glass substrate with a thickness of 0.15mm; heat treatment in a muffle furnace at 680°C for 30 minutes, with a heating rate of 25°C / min; after heat treatment, the two glass substrates are fused and bonded together;

[0062] (2) The glass bonded in step (1) is placed in the second heating zone of the tube furnace as the substrate and the tungsten source at the same time, and the sulfur powder (sulfur source) is placed in the second heating zone upstream of the tube furnace. In the first heating zone, the mass of sulfur powder used is 150mg;

[0063] (3) feed argon at a rate of 80mL / min in the tube furnace describe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com