Polyoxometalate-graphene nano composite material and preparation method and application thereof

A technology of polyoxometalate and nanocomposite materials, which is applied in the direction of active material electrodes, electrical components, electrochemical generators, etc., can solve the problems of low cycle stability, small specific capacity, complex process, etc., and achieve simplified preparation steps , good specific capacity, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

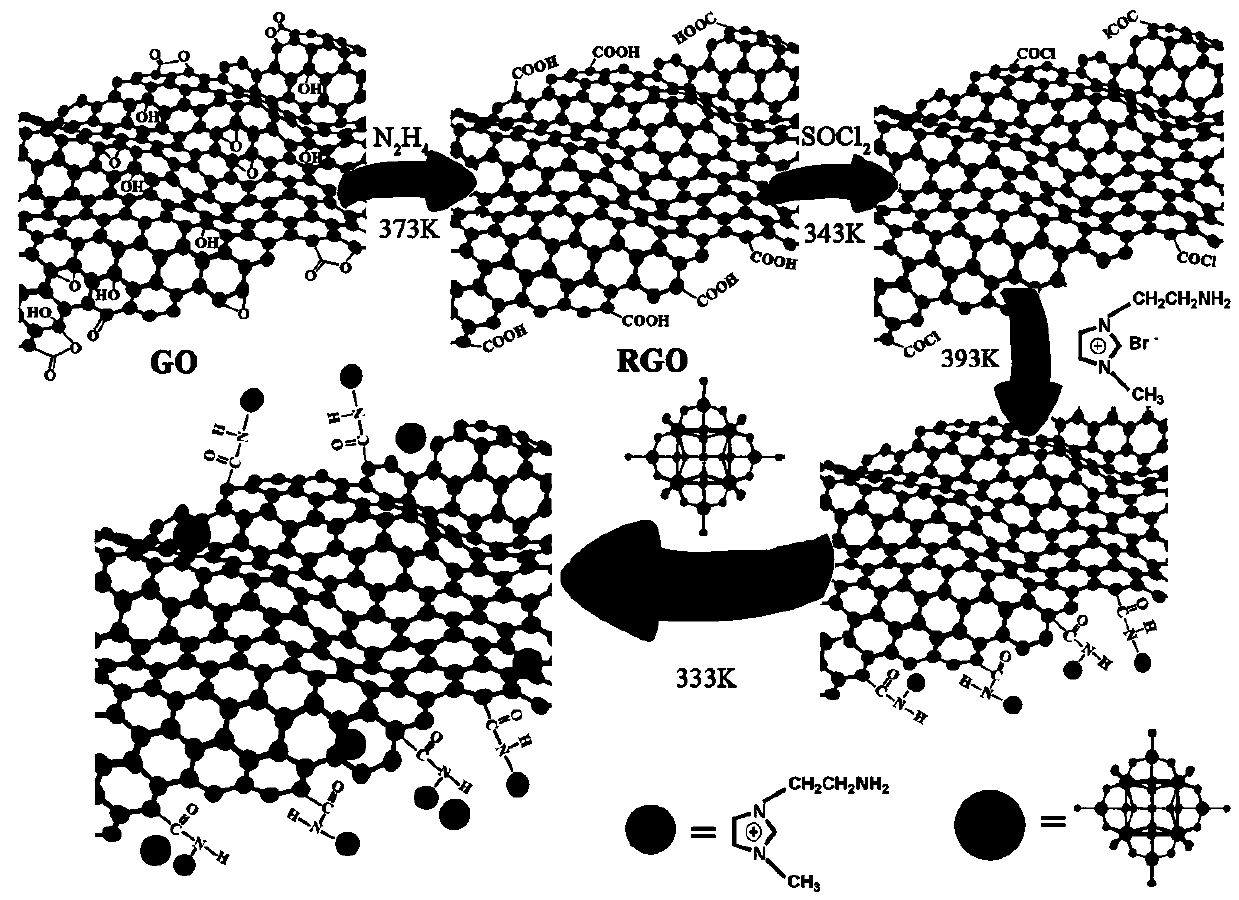

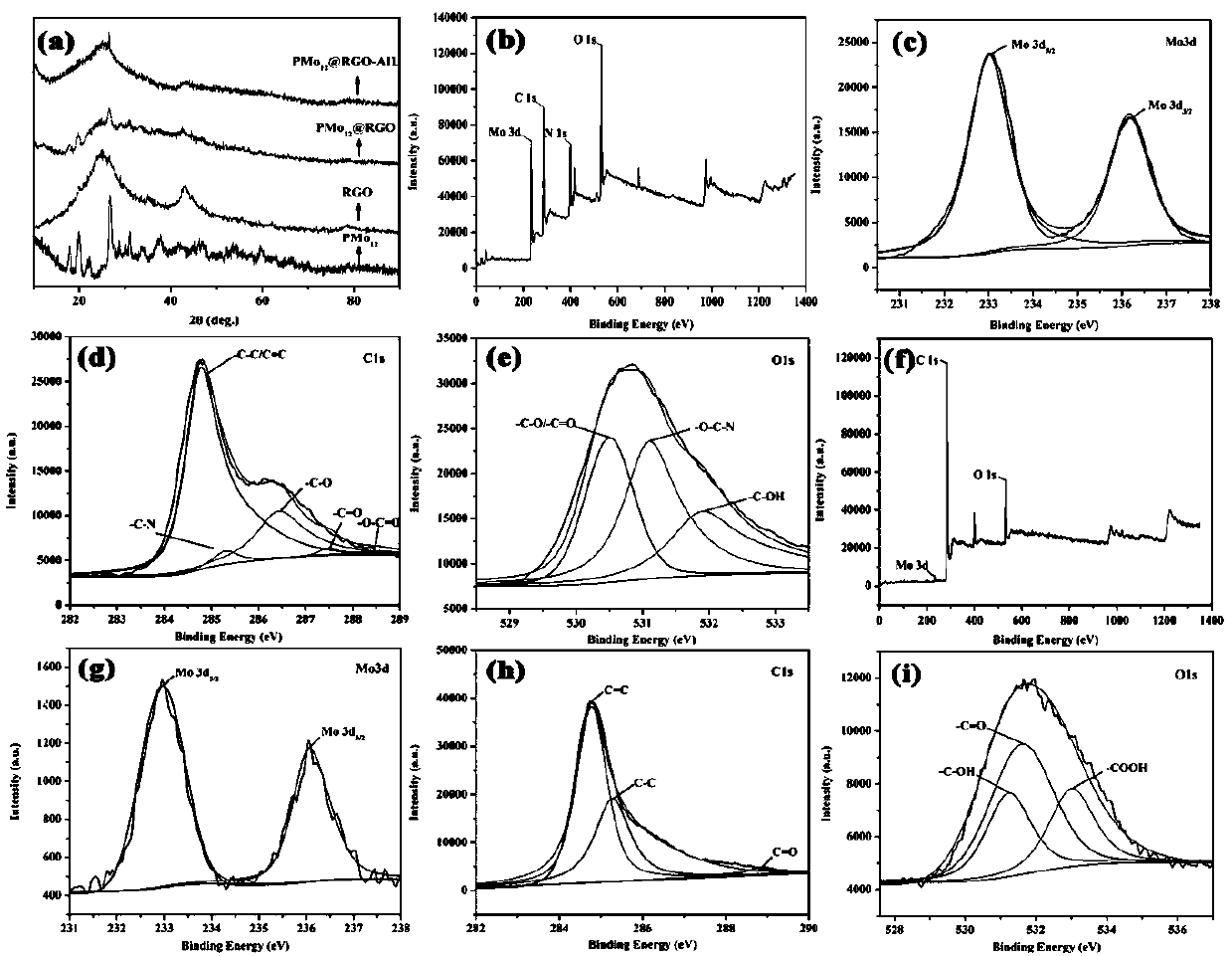

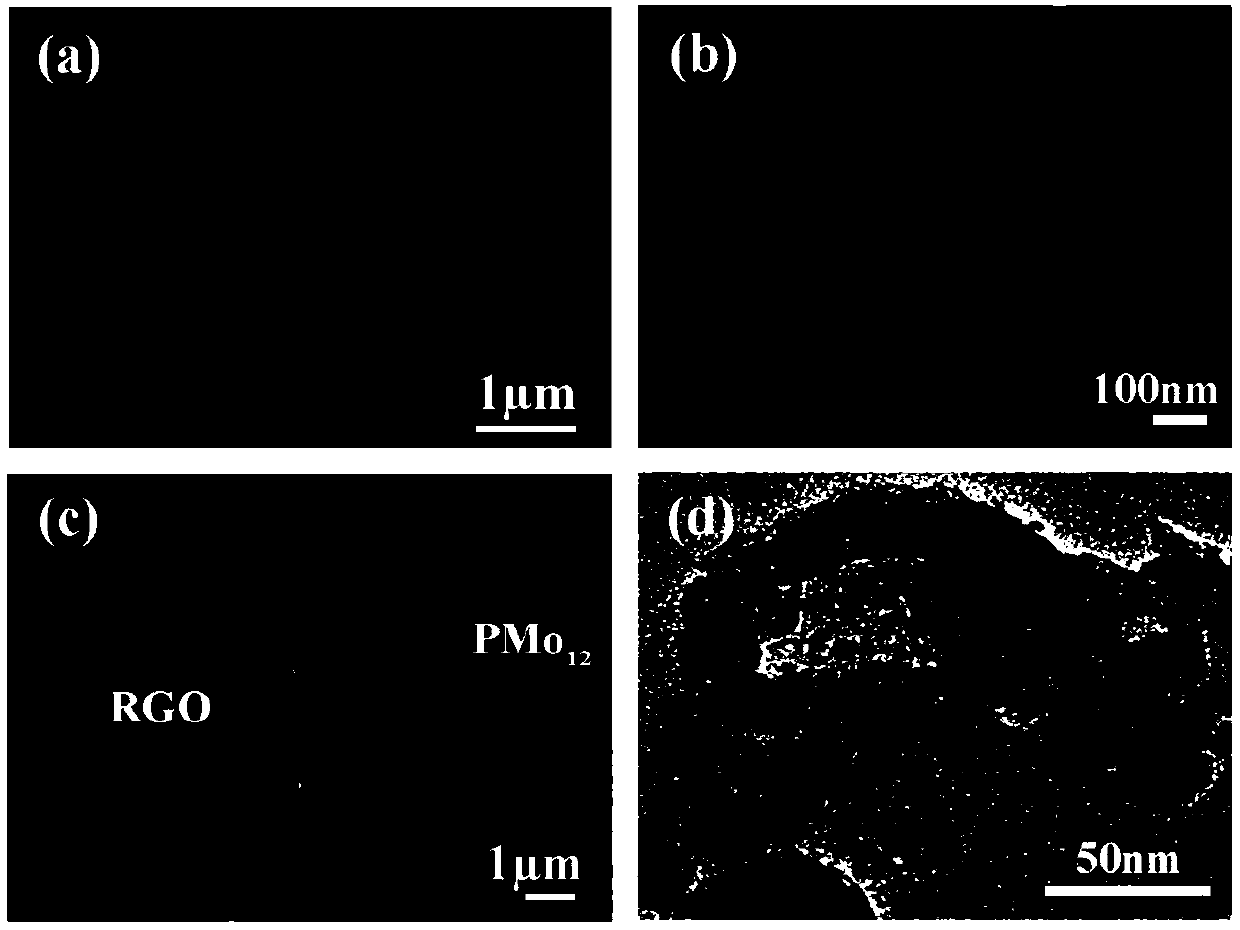

[0037] A preparation method of polyoxometalate-graphene nanocomposite material, comprising the following steps:

[0038] (1) Preparation of amino ionic liquid: Dissolve 9.0 g 0.1 mol of 1-methylimidazole and 22 g 0.1 mol of 2-ethylamine hydrobromide in 50 mL of acetonitrile, stir at 80 °C for 4 h, then add 5 g Mix with 0.1 mol sodium hydroxide, filter to remove the sodium bromide precipitate, and then extract the clear liquid with acetonitrile to obtain a waxy liquid, which is amino ionic liquid (AIL);

[0039] (2) Preparation of reduced graphene: 135 mg graphene and 146 mg hydrazine hydrate (mass fraction 80%) were reacted at 110 °C for 80 min, the product was centrifuged, washed with ethanol and distilled water to obtain reduced graphene (RGO) ;

[0040] (3) Reaction of reduced graphene with amino ionic liquid: take 95 mg of RGO in step (2) and 18 mL of thionyl chloride and reflux at 70 °C for 24 hours to acylchloride RGO, at 12000 r min -1 After centrifugation for 5 minut...

Embodiment 2

[0045] A preparation method of polyoxometalate-graphene nanocomposite material, comprising the following steps:

[0046] (1) Preparation of amino ionic liquid: Dissolve 8.2 g 0.1 mol of 1-methylimidazole and 20.5 g 0.1 mol of 2-ethylamine hydrobromide in 50 mL of acetonitrile, stir at 100 °C for 6 h, and then add 4.5 g 0.1 mol sodium hydroxide and mix well, filter to remove the sodium bromide precipitate generated in the reaction, extract with acetonitrile to obtain a waxy liquid which is amino ionic liquid (AIL);

[0047] (2) Preparation of reduced graphene: 135 mg graphene and 150 mg hydrazine hydrate (mass fraction 80%) were reacted at 110 °C for 90 min, the product was centrifuged, washed with ethanol and distilled water to obtain reduced graphene (RGO) ;

[0048](3) Reaction of reduced graphene with amino ionic liquid: Take 95 mg of RGO in step (2) and 19 ml of thionyl chloride and reflux at 70 °C for 12 hours, then carry out acyl chloride on RGO, at 10000 r min -1 Afte...

Embodiment 3

[0051] A preparation method of polyoxometalate-graphene nanocomposite material, comprising the following steps:

[0052] (1) Preparation of amino ionic liquid: Dissolve 9 g 0.1 mol 1-methylimidazole and 20.5 g 0.1 mol 2-ethylamine hydrobromide in 50 mL of acetonitrile, stir at 90°C for 5 h, then add 4 g 0.1 mol sodium hydroxide and mix well, filter to remove the sodium bromide precipitate generated in the reaction, extract the above solution with acetonitrile (5mL×3) to obtain a waxy liquid which is amino ionic liquid (AIL);

[0053] (2) Preparation of reduced graphene: 135 mg graphene and 135 mg hydrazine hydrate (mass fraction 80%) were reacted at 100︒C for 80 minutes, the product was centrifuged, washed with ethanol and distilled water to obtain reduced graphene (RGO) ;

[0054] (3) Reaction of reduced graphene with amino ionic liquid: take 90 mg of RGO in step (2) and 18 mL of thionyl chloride, reflux at 80 °C for 24 h, then reflux at 10000 r min -1 After centrifuging fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com