High-temperature-resistant enameled wire prepared by 3D printing and preparation method thereof

A 3D printing and 3D printer technology, applied in the direction of bendable conductors, equipment for manufacturing conductive/semiconductive layers, conductors, etc., can solve the problems of unsuitable preparation methods, blank enameled wire manufacturing fields, and heat consumption, etc., to achieve The effect of overcoming the difficulty of industrialized batch manufacturing, overcoming the difficulty of obtaining, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A high temperature resistant enamelled wire prepared by 3D printing is a 3D printed polyimide high temperature resistant enameled wire, which has a viscosity of 10 4 CPS commercial carbon paste slurry 3D printed conductive inner core, and a viscous slurry made of 40 parts by mass of high-temperature resistant insulating photocurable polyamic acid, and simultaneously 3D printed high-temperature insulating polyamide formed by high-temperature heat treatment The outer layer of imide is composed; the high temperature resistant insulating polyimide includes 40 parts by mass of photocurable polyamic acid with a molecular weight of 40000, 40 parts of solvent, 20 parts of diluent, and 3 parts of photoinitiator; The solvent is N-N dimethylformamide; the diluent polyethylene glycol diacrylate; the photoinitiator is benzoin dimethyl ether.

Embodiment 2

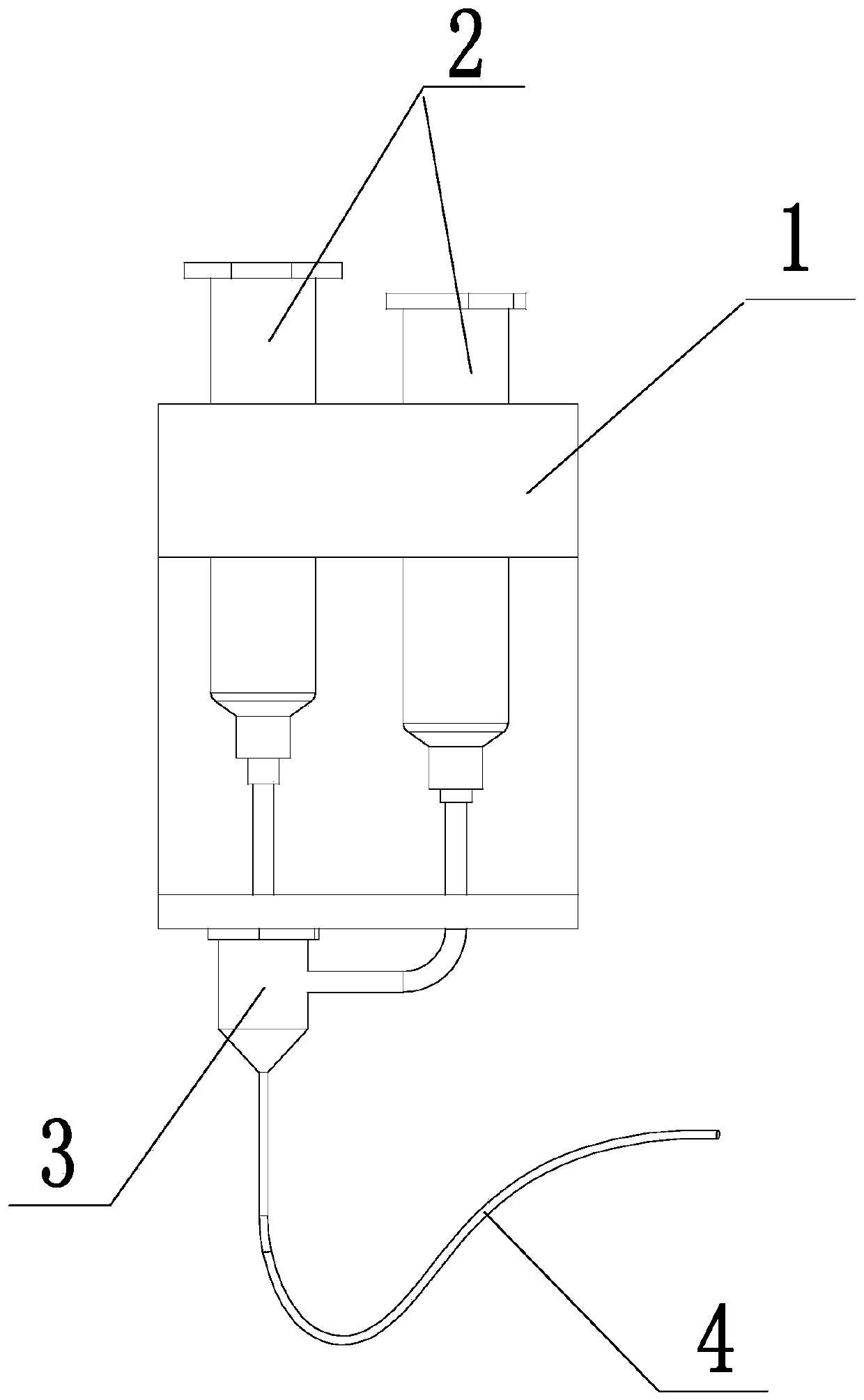

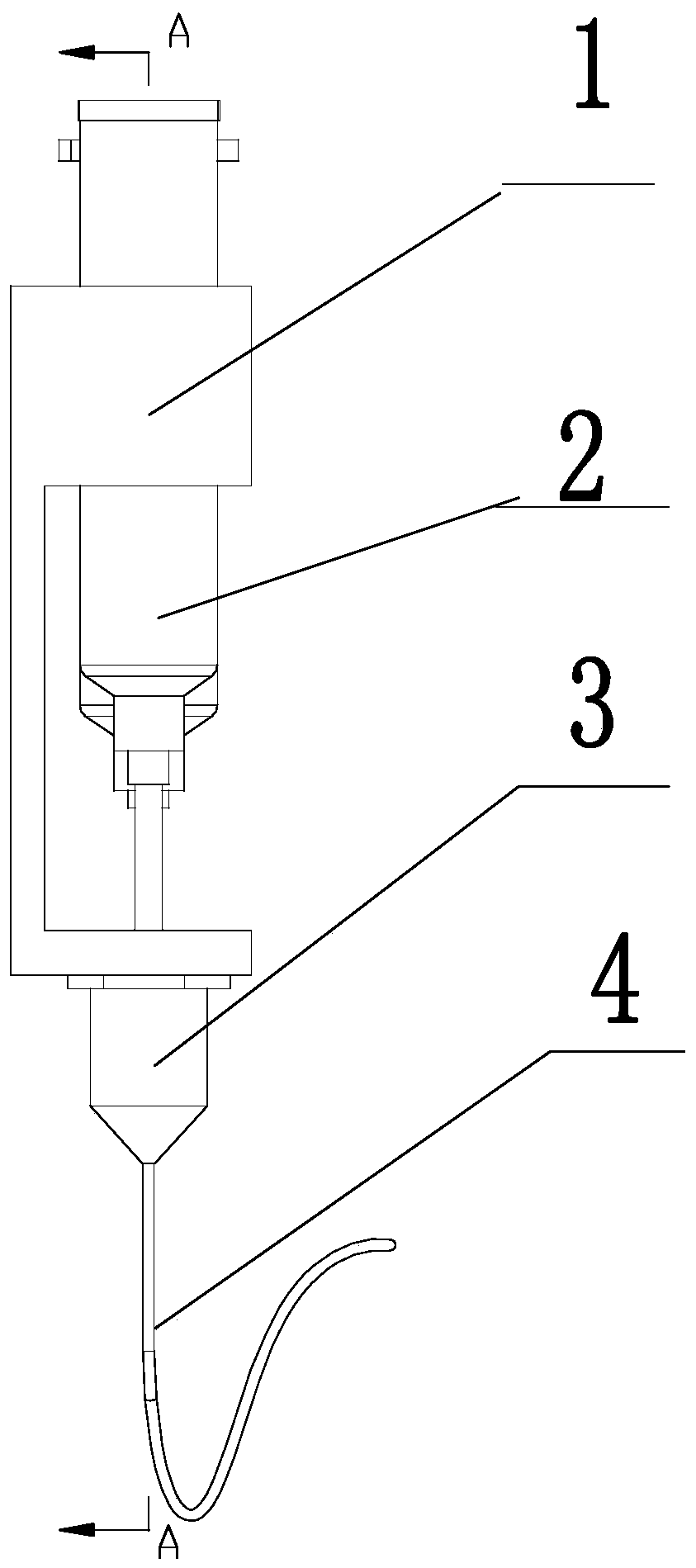

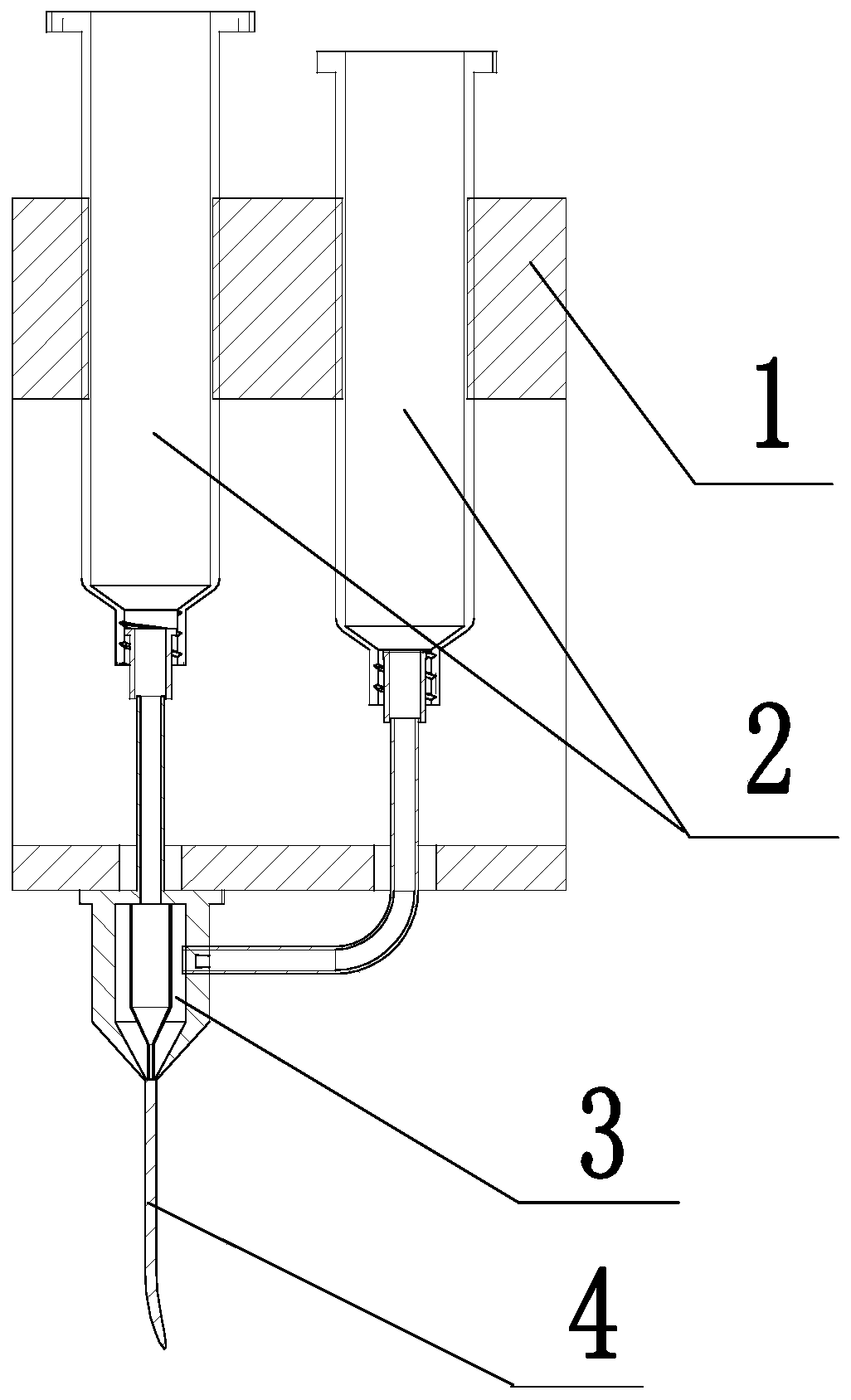

[0021]A preparation method of high temperature resistant enamelled wire prepared by 3D printing is a preparation method of high temperature resistant polyimide enameled wire prepared by 3D printing. Firstly, nano conductive silver is made into a paste with a viscosity of 20 Pa. s; 50 parts by mass of photocurable polyamic acid with a molecular weight of 40000, 40 parts of solvent N-N dimethylformamide, 10 parts of thinner polyethylene glycol diacrylate, 2.5 parts of photoinitiator benzoin dimethyl ether Mix and prepare the photocurable outer insulating layer polyimide paste, the viscosity of which is 20 Pa.s; and the conductive silver paste and polyimide paste are extruded through the dual-material coaxial nozzle UV-assisted direct writing 3D printer can controlly extrude the nano-silver conductive inner core and polyimide high-temperature-resistant insulating material outer layer at the same time, and then the ultraviolet light source is assisted to cure and form the preformed...

Embodiment 3

[0023] A high-temperature-resistant enamelled wire prepared by 3D printing is a 3D-printed polyimide high-temperature-resistant enamelled wire, which is made of nano-silver powder to make a conductive inner core for 3D printing of paste, and is made of 45 parts by mass. High-temperature insulating polyamic acid is made of viscous slurry and simultaneously 3D printed and formed by high-temperature heat treatment to form an outer layer of high-temperature insulating polyimide material; the high-temperature insulating polyamic acid slurry includes 45 parts by mass of molecular weight 100000 photocurable polyamic acid, 40 parts of solvent, 15 parts of diluent, 3 parts of photoinitiator; the solvent is N-N dimethylacetamide; the diluent is 1,6-hexanediol diol Acrylate; the photoinitiator is I phenyl bis (2,4,6 trimethylbenzoyl) phosphine oxide (819).

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com