Preparation method and application of starch-based biological latex

A biological latex and starch-based technology, applied in the field of coated paper, to achieve the effect of wide source of raw materials, moderate viscosity, and avoid over-reliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

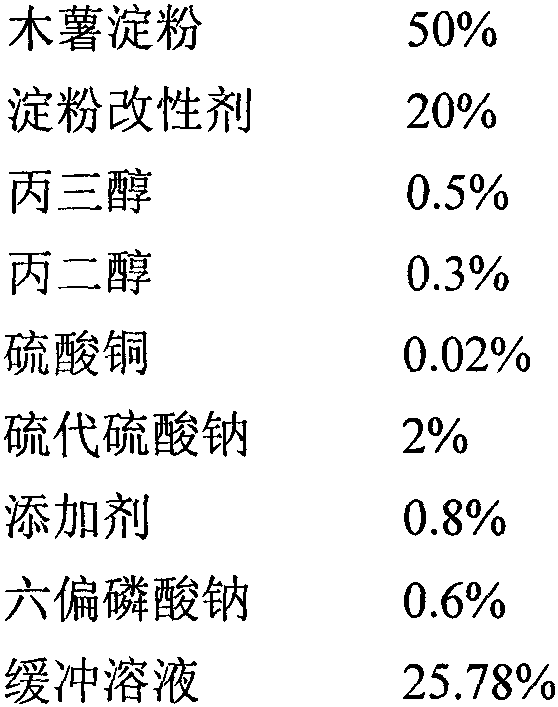

[0027] A kind of starch-based biological latex, after the original tapioca starch is ground by a ball mill for 2 hours, the suspension is prepared by mass percentage, including the following components:

[0028]

[0029] crafting process:

[0030] The original tapioca starch and zirconia beads with different diameters were placed in a ball mill tank at a mass ratio of 1:1.5, and after grinding for 1 hour, the rotating direction of the ball mill was changed and the grinding was continued for 1 hour, and then the cooled starch was taken out. Make starch and buffer solution into starch milk according to the recipe, put it in a 37°C water bath, add starch modifiers, glycerol and propylene glycol, heat to 95°C for gelatinization, keep it warm for 30min, and cool to room temperature. Add oxidizing agent and copper sulfate and heat up to 40°C, react for 60min under cantilever stirrer stirring, adjust system pH to 9, add additives and cross-linking agent, heat up to 70°C, react for...

Embodiment 2

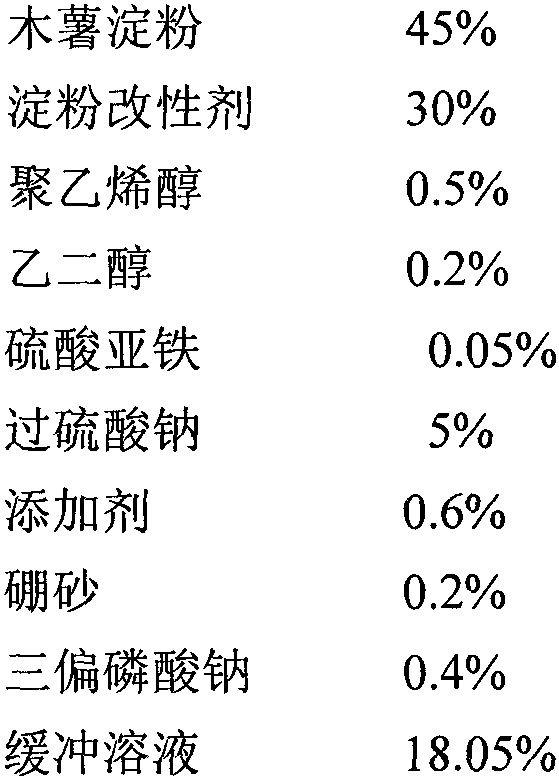

[0032] A kind of starch-based biological latex, after the original cassava starch is ground by a ball mill for 8 hours, the suspension is prepared by mass percentage, including the following components:

[0033]

[0034] crafting process:

[0035] The original tapioca starch and zirconia beads with different diameters were placed in a ball mill tank at a mass ratio of 1:1.5. After grinding for 1 hour, the rotation direction of the ball mill was changed and the grinding was continued for 1 hour. Grinding in this way was repeated for 8 hours, and the cooled starch was taken out. According to the formula, starch and buffer solution are formulated into starch milk, placed in a 37°C water bath, added with starch modifiers, polyvinyl alcohol, and ethylene glycol, heated to 80°C for gelatinization, kept for 50 minutes, and cooled to room temperature. Add oxidizing agent and copper sulfate and heat up to 30°C, react for 100min under cantilever stirrer stirring, adjust system pH to ...

Embodiment 3

[0037] The bio-latex obtained in Examples 1 and 2 of the present invention directly replaces carboxylated styrene-butadiene latex at a substitution ratio of 30%, and is used as a coating adhesive in paper coating. They are respectively marked as samples 1 and 2. The bio-latex prepared by mechanically pretreated starch is marked as 3, and the performance of the finished paper is tested by single-sided single-coating with commercially available electrostatic copy paper as the base paper as follows:

[0038] sample 1 2 3 Carboxylated styrene-butadiene latex Coating solid content% 60 58 59 59 Coating weight g / m 2

[0039] It can be seen from the above table that the starch-based biological latex prepared by the ball milling pretreated starch and biochemical composite modification provided by the present invention is applied to coated paper, partially replacing carboxylated styrene-butadiene latex, and the whiteness of coated paper is significantly impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com