Three-dimensional graphene/black titanium dioxide composite material and preparation method and application thereof

A technology of black titanium dioxide and composite materials, which is applied in the field of three-dimensional graphene/black titanium dioxide composite materials and its preparation, can solve the problems of insufficient ability to adsorb pollutants, difficulty in recycling and repeated use, small particle size, etc., and achieve decomposition and Effects of deodorization, rapid and efficient enrichment, and high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of three-dimensional graphene is not particularly limited, and it can be prepared by methods known in the art, preferably template-assisted CVD method, impregnated carbonization method, or hydrothermal method followed by carbonization method to prepare SP2 hybridized highly conductive three-dimensional graphene. In particular, the hydrothermal method can prepare three-dimensional graphene on a large scale.

[0052] In the process of preparing three-dimensional graphene, a dopant source can be introduced to prepare element-doped three-dimensional graphene. The dopant source (element source) used when preparing the doped three-dimensional graphene can be, for example, thiourea, NH 4 OH, NH 4 Cl, phosphoric acid, H 2 One or more mixtures of S, sodium borohydride.

[0053] The template-assisted CVD method refers to the use of chemical vapor deposition to deposit graphene on a three-dimensional template and then remove the template.

[0054] The th...

Embodiment 1

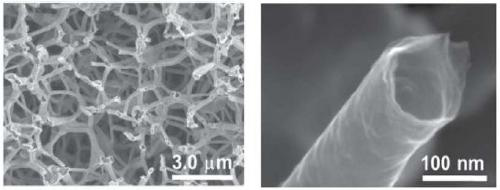

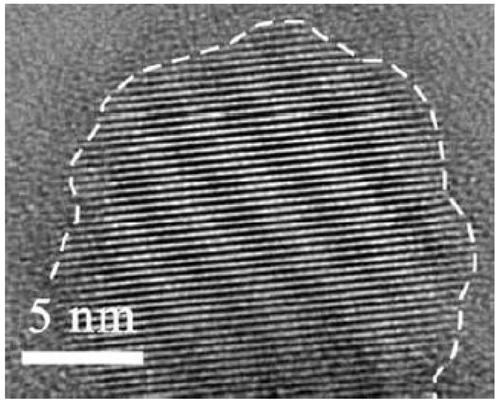

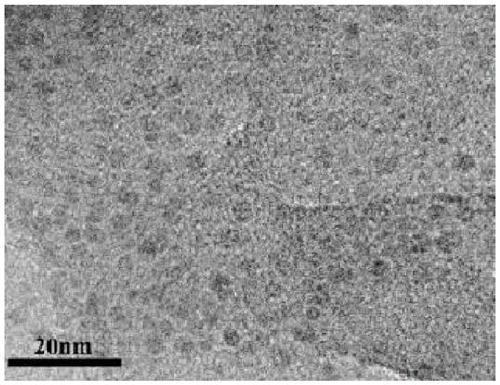

[0083] First, the three-dimensional graphene network was prepared by chemical vapor deposition (CVD) using silica nanotubes as templates. After the template was removed with hydrofluoric acid, three-dimensional graphene nanotubes were prepared by chemical vapor deposition. Its scanning electron microscope picture is as figure 1 As shown, it can be seen that the prepared graphene nanotubes have a pore diameter of about 1-3 microns and a tube diameter of about 80-120 nm. After the magnesium powder and P25 are fully mixed and sintered in a vacuum furnace at 500 degrees Celsius for 2 hours, then repeatedly washed with hydrochloric acid and deionized water, and dried to obtain black titanium oxide. Its transmission electron microscope image is shown in figure 2 As shown, it can be seen that the core part presents an ordered crystalline structure, and the outer layer has a disordered amorphous structure layer; from its absorption spectrum as Figure 4 As shown, it can be seen tha...

Embodiment 2

[0086] First, using nickel foam as a template, a three-dimensional graphene network was prepared by chemical vapor deposition (CVD). After removing the template with hydrofluoric acid, three-dimensional graphene nanotubes were prepared by chemical vapor deposition. Disperse 20 g of black titanium dioxide prepared by the Mg reduction method in water, and perform hydrothermal composite with 3 g of the three-dimensional graphene prepared above. The hydrothermal temperature is 180° C., and the hydrothermal time is 6 h. After drying, crush it into 10-30 micron particles, disperse the particles in 1L NMP solution, add 10g of low molecular weight phenolic resin at the same time, stir for 80 hours, load it on the polypropylene mesh by impregnation method, and then treat it at 120°C for 1 hour to build Full spectrum absorbing photocatalytic mesh.

[0087] In the methyl orange degradation test, the methyl orange with a concentration of 10mg / l can decompose over 95% in 3 minutes, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com