Pickering high internal phase emulsion, 3D printing porous support material and preparation method of Pickering high internal phase emulsion

A technology of high internal phase emulsion and water phase, applied in the fields of pharmaceutical formula, medical science, prosthesis, etc., can solve the problems of long dialysis time period, acrylamide toxicity, high production cost, etc., and achieve good biocompatibility and biological activity , pore diameter and pore throat size reduction, and the effect of enhanced mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

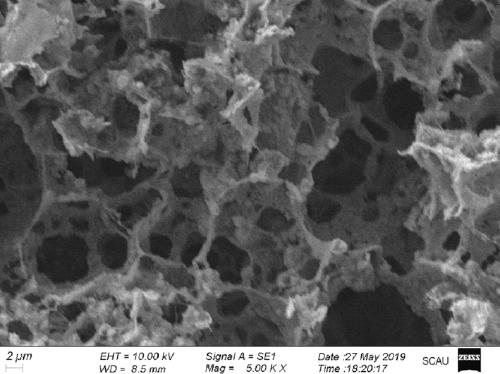

Embodiment 1

[0029] A method for preparing 3D printing porous scaffold materials with Pickering high internal phase emulsion, comprising the following steps:

[0030] (1) Weigh 0.1 g of polycaprolactone (PCL) and add it to 10 ml of dichloromethane, and disperse with magnetic stirring at room temperature for 30 minutes to form the oil phase; in addition, weigh 1.5 g of gelatin, 0.6 g of collagen, 0.03 Add 1 g of genipin and 1.08 g of hydroxyapatite into 3 mL of deionized water, stir and disperse at room temperature for 30 min to form the water phase; use a pipette to measure the above oil phase and add it to the water phase (water phase The volume ratio between the oil phase part and the oil phase part is 3:10), use a vortex mixer to shake for 10 minutes, leave the cross-linking reaction for 24 hours, and form an oil-in-water emulsion for later use.

[0031] (2) Import the oil-in-water emulsion obtained in the above step (1) after 24 hours of cross-linking reaction into the syringe of the 3...

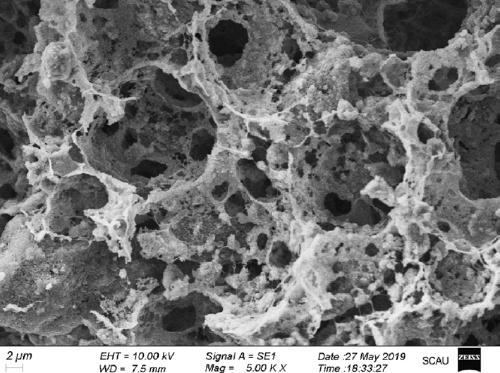

Embodiment 2

[0033]A method for preparing 3D printing porous scaffold materials with Pickering high internal phase emulsion, comprising the following steps:

[0034] (1) Weigh 0.2 g of polycaprolactone (PCL) into 10 ml of dichloromethane, disperse with magnetic stirring at room temperature for 30 minutes, and form an oil phase; in addition, weigh 1.5 g of gelatin, 0.6 g of collagen, 0.03 Add 1 g of genipin and 1.08 g of hydroxyapatite into 3 mL of deionized water, stir and disperse at room temperature for 30 min to form the water phase; use a pipette to measure the above oil phase and add it to the water phase (water phase The volume ratio between the oil phase part and the oil phase part is 3:10), use a vortex mixer to shake for 10 minutes, leave the cross-linking reaction for 24 hours, and form an oil-in-water emulsion for later use.

[0035] (2) Import the oil-in-water emulsion obtained in the above step (1) after 24 hours of cross-linking reaction into the syringe of the 3D printer, st...

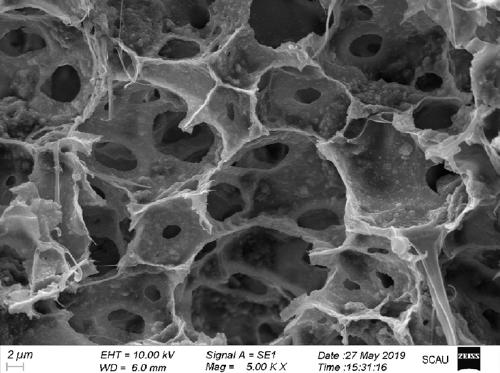

Embodiment 3

[0037] A method for preparing 3D printing porous scaffold materials with Pickering high internal phase emulsion, comprising the following steps:

[0038] (1) Weigh 0.4 g of polycaprolactone (PCL) and add it to 10 ml of dichloromethane, and disperse with magnetic stirring at room temperature for 30 minutes to form the oil phase; in addition, weigh 1.5 g of gelatin, 0.6 g of collagen, 0.03 Add 1 g of genipin and 1.08 g of hydroxyapatite into 3 mL of deionized water, stir and disperse at room temperature for 30 min to form the water phase; use a pipette to measure the above oil phase and add it to the water phase (water phase The volume ratio between the oil phase part and the oil phase part is 3:10), use a vortex mixer to shake for 10 minutes, leave the cross-linking reaction for 24 hours, and form an oil-in-water emulsion for later use.

[0039] (2) Import the oil-in-water emulsion obtained in the above step (1) after 24 hours of cross-linking reaction into the syringe of the 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com