Preparation method of flavored tuna nutritional biological products

A technology for biological products and tuna, applied in microorganism-based methods, biochemical equipment and methods, bacteria used in food preparation, etc., can solve the problems of waste of resources, perishable deterioration, etc., to achieve convenient operation and increase product safety. , the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

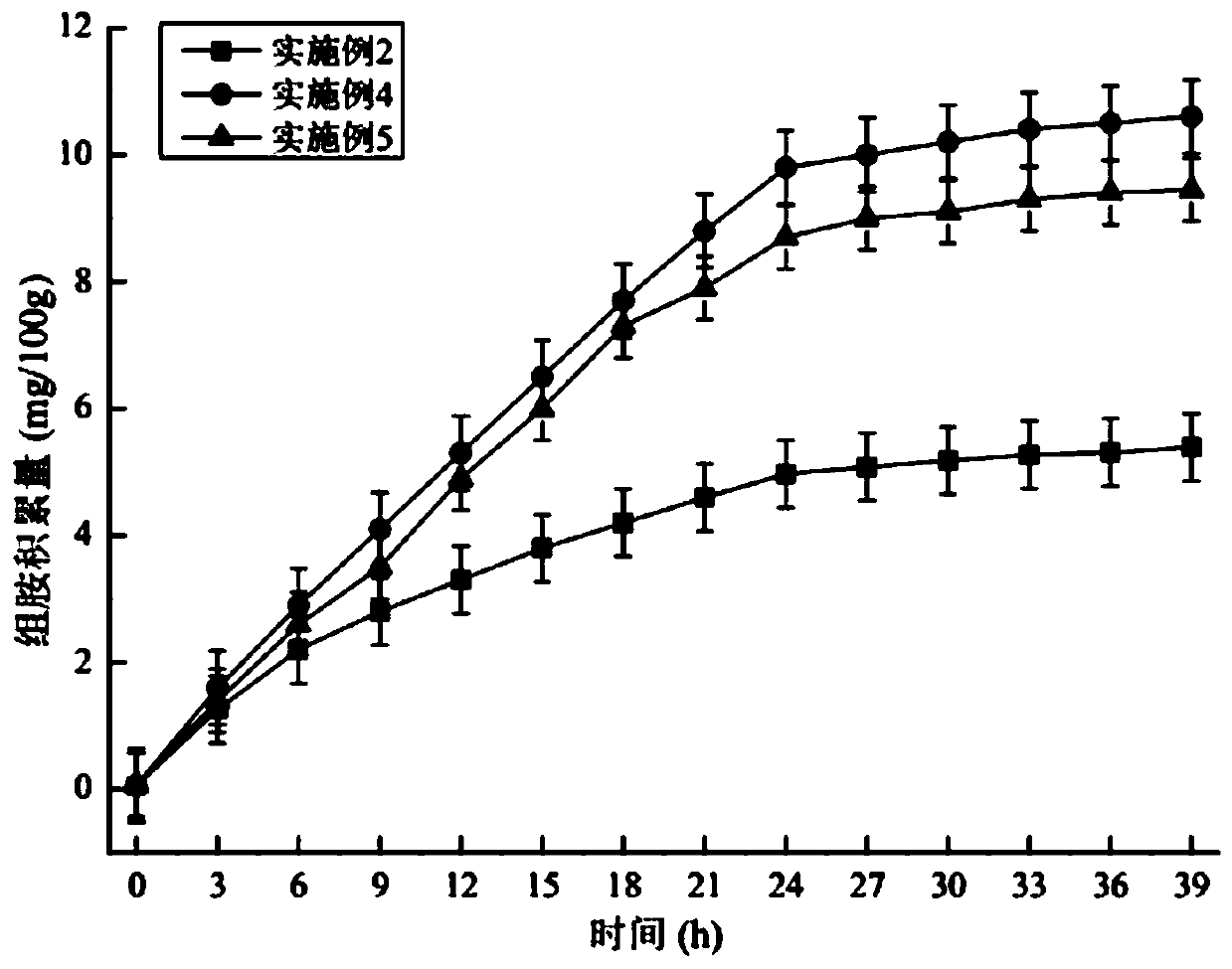

Examples

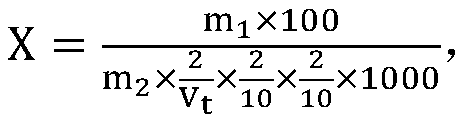

Embodiment 1

[0026] A method for preparing flavored tuna nutritional biological products, comprising: providing a slurry containing water and tuna by-products; providing MRS broth medium, the above-mentioned medium is used for cultivating probiotics; providing expansion treatment, the above-mentioned expansion treatment is used for The protein conjugate is subjected to pore expansion treatment; bacterial enzyme combined treatment is provided, and the bacterial enzyme combined treatment is used to convert soluble protein; and the soluble protein is recovered; the conversion rate of the above soluble protein is at least 40%. This method uses probiotics and protease to extract protein from tuna by-products through biotransformation treatment, which can obtain more nutritious and easier to absorb small peptide molecules and active factors, and improve the flavor of tuna nutritional products. It has improved the added value of tuna by-products and opened the way for biotransformation technology ...

Embodiment 2

[0036] A method for preparing flavored tuna nutritional biological products, the specific steps are as follows:

[0037] (1) Wash the by-products of tuna, crush and homogenate it, then place it in a high-pressure steam sterilizer at 120°C for 30 minutes, then store it in a -20°C refrigerator for later use, and thaw it under running water for 30 minutes before use;

[0038] (2) Inoculate the activated Streptococcus thermophilus on the MRS broth medium, culture it for 24 hours at a temperature of 37°C and a shaking table with a rotation speed of 120r / min to obtain a probiotic bacterial liquid for use. The concentration of bacteria in the medium is at least 1×10 14 cfu / L;

[0039] (3) Mix the homogenate of tuna by-products with 5 times the amount of expansion solution, and heat it in a water bath at 60°C for 45 minutes to obtain the expansion slurry. The above expansion solution includes sodium bicarbonate, 2.5% sodium bicarbonate and 2.5 % of sodium carbonate, 0.07% of 4,4'-di...

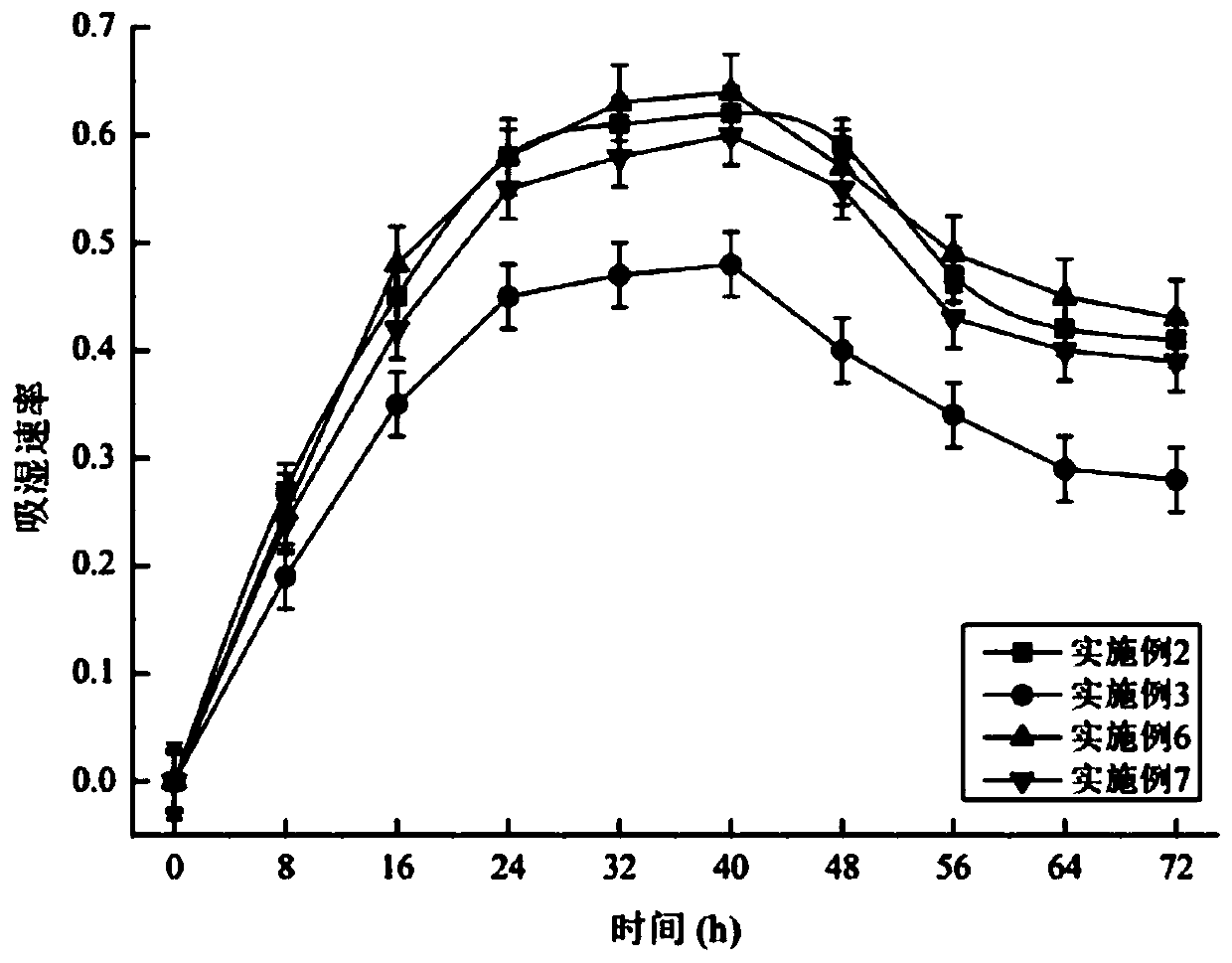

Embodiment 3

[0043] The only difference between this example and Example 2 is that in step (4) when protease is added, 0.07% thiodipropionic acid and 0.03% 3,5-dinitrate are added to the system by weight In the process of loosening protein conjugates, proteases expose some hydrophobic residues, resulting in increased bitterness of the product, which in turn negatively affects the taste and eating experience of the product. After the above two are added to the system, use Acidic groups and hydrophobic residues combine in the form of non-covalent bonds, and form folding groups in the system, so that hydrophobic residues can be enriched and buried inside the group, thereby reducing the contact between hydrophobic residues and taste buds, reducing On the other hand, this folded group can prevent moisture from diffusing inward under external storage conditions, thereby reducing the hygroscopicity of the product, preventing the loss of nutrition and flavor, and extending the shelf life of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com