Environment-friendly textile sizing agent and preparation method thereof

A kind of textile sizing, environment-friendly technology, applied in the field of environment-friendly textile sizing and its preparation, can solve the problems such as the difficulty of separating the serosa with hard yarn, the difficulty of high COD content, and the low weaving efficiency, so as to reduce the secondary hairiness, adjust the The sizing process is simple and the effect of reducing the cost of sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An environment-friendly textile size, which is composed of the following raw materials in parts by mass: 30 parts of modified starch, 0.4 part of potassium pyrophosphate, 2 parts of polyethylene terephthalate, 4 parts of polyacrylic size, 0.8 part of urea , 6 parts of calcium chloride, 2 parts of bentonite, 1 part of sodium lignosulfonate, 1 part of defoamer and 28 parts of deionized water

[0022] The polyacrylic slurry is selected from one or more of acrylic acid, acrylamide, acrylonitrile, vinyl acetate, styrene, methyl methacrylate or methyl acrylate.

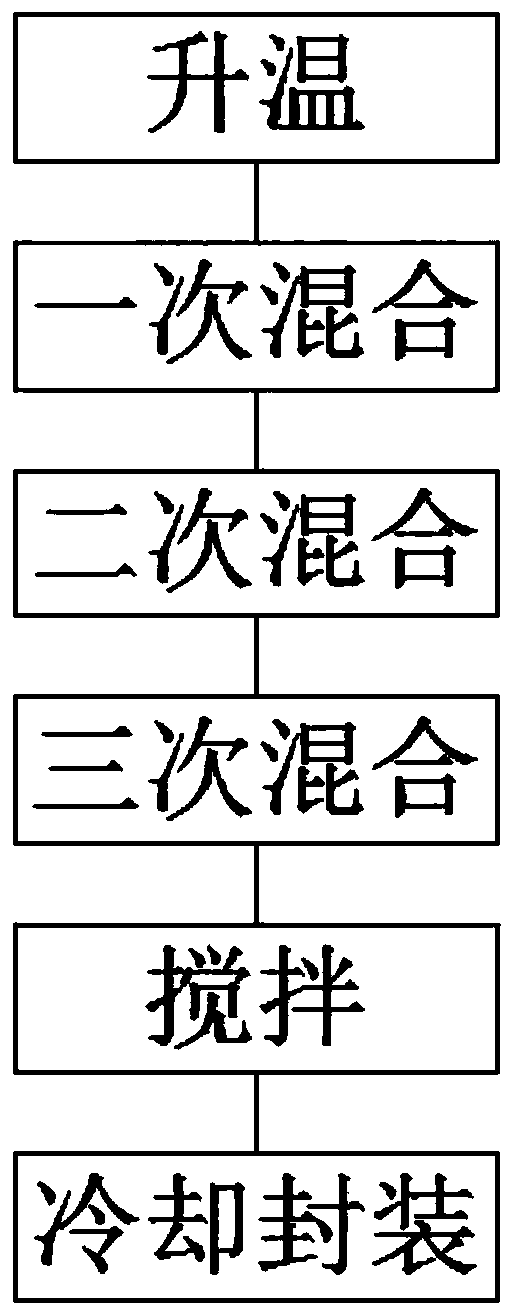

[0023] A preparation method of an environment-friendly textile size, through the steps of heating up, primary mixing, secondary mixing, tertiary mixing, stirring and cooling and encapsulating, the preparation of the environment-friendly textile size is completed; the specific steps are as follows:

[0024] (1) Heating: 28 parts of deionized water are added to the reactor, and the temperature is raised to 42 degrees C...

Embodiment 2

[0032] An environment-friendly textile size, which is composed of the following raw materials in parts by mass: 40 parts of modified starch, 0.6 parts of potassium pyrophosphate, 8 parts of polyethylene terephthalate, 12 parts of polyacrylic size, 2.2 parts of urea , 10 parts of calcium chloride, 4 parts of bentonite, 3 parts of sodium lignosulfonate, 3 parts of defoamer and 50 parts of deionized water.

[0033] The polyacrylic slurry is selected from one or more of acrylic acid, acrylamide, acrylonitrile, vinyl acetate, styrene, methyl methacrylate or methyl acrylate.

[0034] A preparation method of an environment-friendly textile size, through the steps of heating up, primary mixing, secondary mixing, tertiary mixing, stirring and cooling and encapsulating, the preparation of the environment-friendly textile size is completed; the specific steps are as follows:

[0035] (1) Heating: 50 parts of deionized water are added to the reactor, and the temperature is raised to 48 de...

Embodiment 3

[0043] An environment-friendly textile size, which is composed of the following raw materials in parts by mass: 35 parts of modified starch, 0.5 parts of potassium pyrophosphate, 5 parts of polyethylene terephthalate, 8 parts of polyacrylic size, and 1.5 parts of urea , 8 parts of calcium chloride, 3 parts of bentonite, 2 parts of sodium lignosulfonate, 2 parts of defoamer and 39 parts of deionized water.

[0044] The polyacrylic slurry is selected from one or more of acrylic acid, acrylamide, acrylonitrile, vinyl acetate, styrene, methyl methacrylate or methyl acrylate.

[0045] A preparation method of an environment-friendly textile size, which completes the preparation of an environment-friendly textile size through the steps of heating up, primary mixing, secondary mixing, tertiary mixing, stirring, and cooling and encapsulation; the specific steps are as follows:

[0046] (1) Heating: 39 parts of deionized water are added to the reactor, and the temperature is raised to 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com