Perovskite solar cell and preparing method thereof

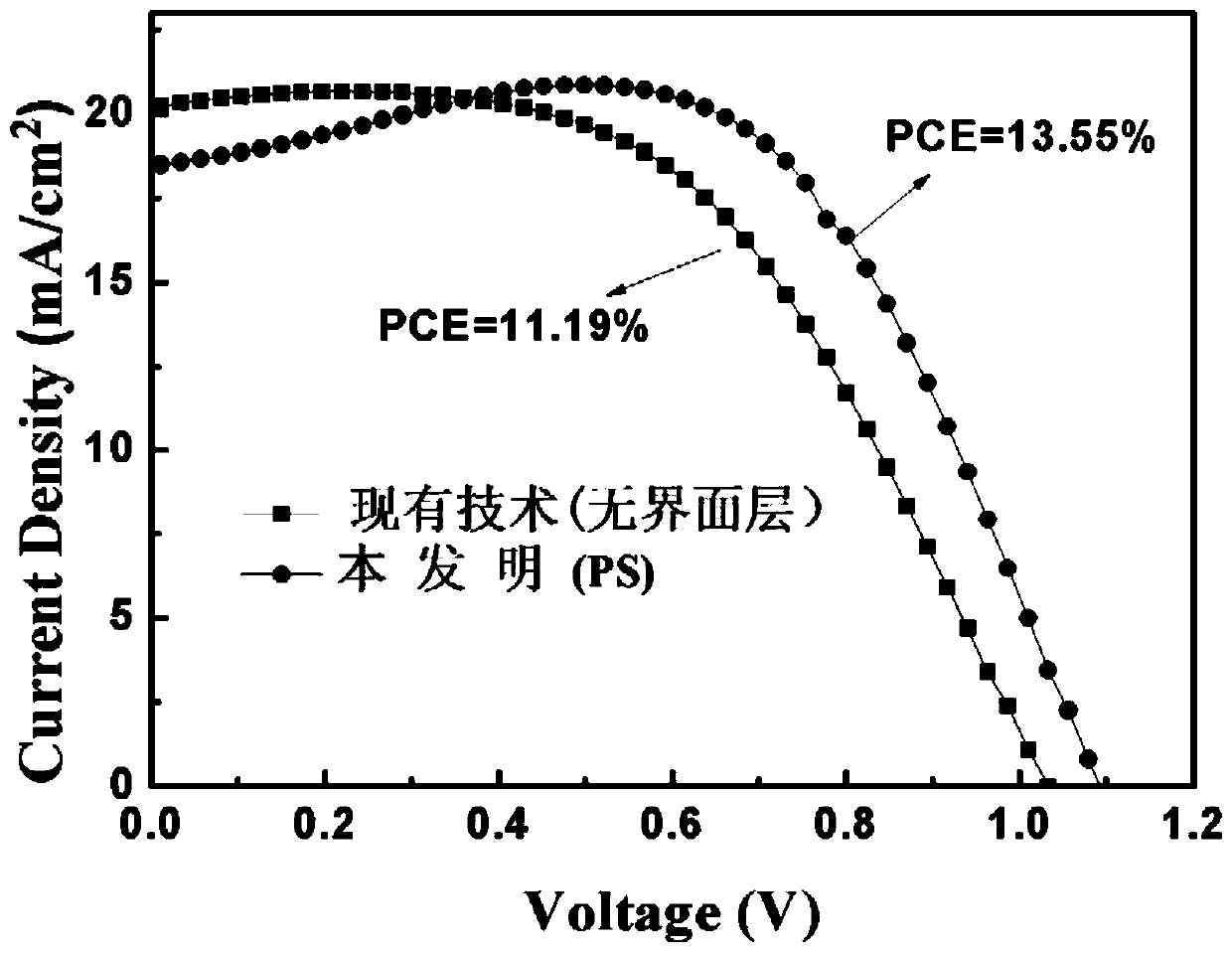

A solar cell and perovskite technology, applied in the field of solar cells, can solve problems such as high cost, poor film formation, and poor repeatability stability, and achieve the effects of improving quality, improving crystal phase quality, and optimizing interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method for preparing the above-mentioned perovskite solar cell, comprising the following steps:

[0036] Step 1: Place the substrate with transparent electrodes in deionized water, acetone, and ethanol in sequence for ultrasonic cleaning, and use ozone plasma to clean after drying;

[0037] Step 2: Using ethanol as a solvent, prepare a 5 mg / mL nano-titanium dioxide solution, spin-coat the nano-titanium dioxide solution on the transparent electrode at a spin-coating speed of 4000 rpm, and then perform annealing treatment to obtain an electron transport layer;

[0038] Step 3: Using chlorobenzene as a solvent, configure a polymer solution with a concentration of 1 mg / mL, spin-coat the polymer solution on the electron transport layer at a spin-coating speed of 3000 rpm, and then perform annealing treatment to obtain an interface modification layer. The polymer solution is polystyrene solution, polymethyl methacrylate soluti...

Embodiment 1

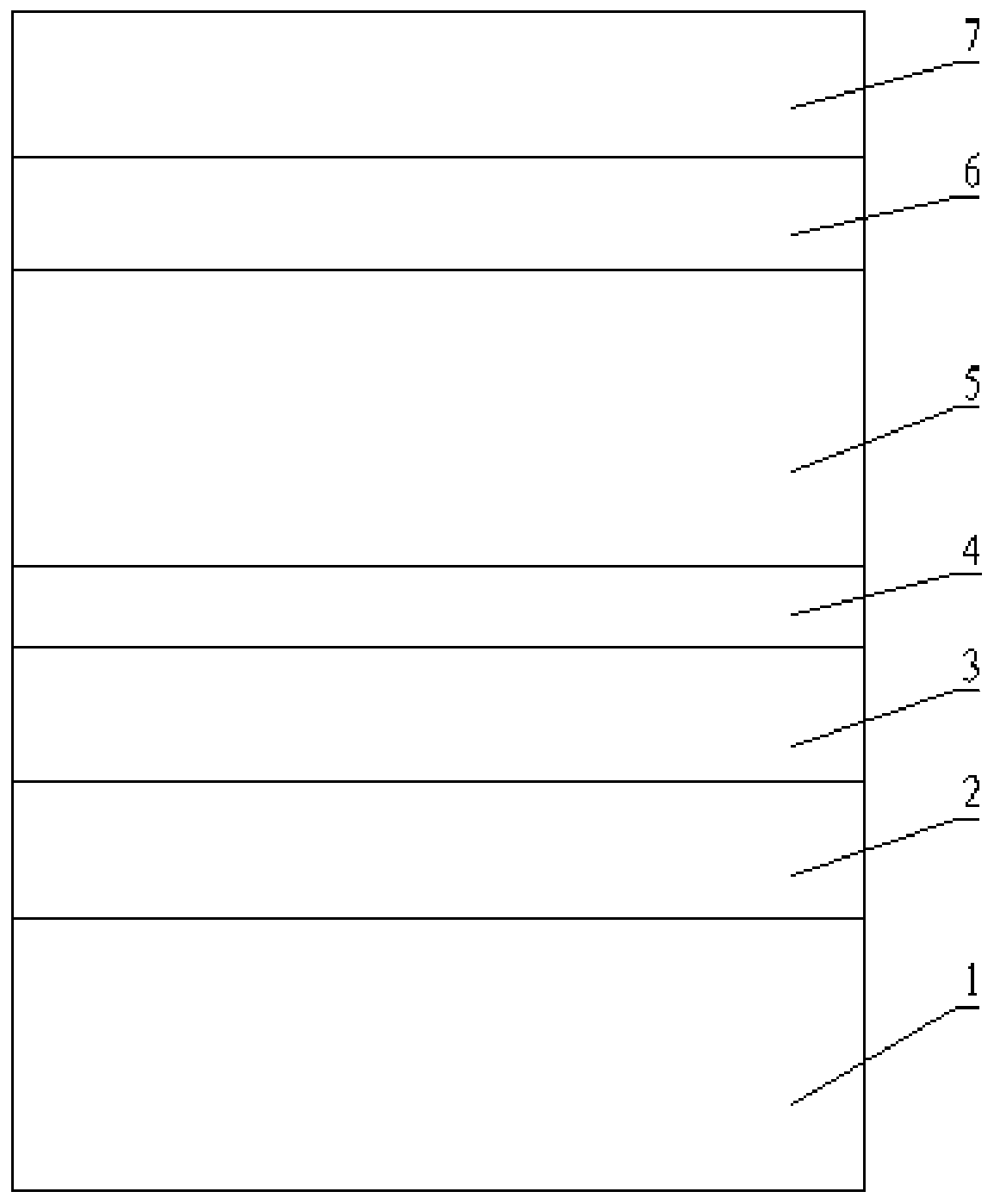

[0049] A perovskite solar cell, comprising from bottom to top: a substrate, a transparent electrode, an electron transport layer, an interface modification layer, a perovskite light-absorbing layer, a hole transport layer, and a top electrode;

[0050] The substrate is a glass substrate; the transparent electrode is an indium tin oxide film;

[0051] The electron transport layer is a nano-titanium dioxide thin film, and the thickness of the electron transport layer is 40nm;

[0052] The interface modification layer is a polymethylmethacrylate film, and the thickness of the interface modification layer is 8nm;

[0053] The specific composition of the perovskite light-absorbing layer is: Cs 0.05 FA 0.81 MA 0.14 PB 2.55 Br 0.45 ;

[0054] The hole transport layer is an organic or inorganic hole transport film with higher hole transport properties;

[0055] The top electrode is an electrode that is composited with silver and a dielectric layer and has the function of capturin...

Embodiment 2

[0058] A perovskite solar cell, comprising from bottom to top: a substrate, a transparent electrode, an electron transport layer, an interface modification layer, a perovskite light-absorbing layer, a hole transport layer, and a top electrode;

[0059] The substrate is a glass substrate; the transparent electrode is a fluorine tin oxide film;

[0060] The electron transport layer is a nano-titanium dioxide thin film, and the thickness of the electron transport layer is 30nm;

[0061] The interface modification layer is a polyvinyl alcohol (PVA) film, and the thickness of the interface modification layer is 9nm;

[0062] The specific composition of the perovskite light-absorbing layer is: Cs 0.05 FA 0.81 MA 0.14 PB 2.55 Br 0.45 ;

[0063] The hole transport layer is an inorganic hole transport film with higher hole transport properties;

[0064] The top electrode is an electrode composed of aluminum and a dielectric layer with the function of capturing electrons;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap