Intermediate infrared thulium-holmium co-doped sesquioxide laser single-crystal optical fiber, and preparation method and application thereof

A sesquioxide and infrared laser technology, which is applied in chemical instruments and methods, lasers, single crystal growth, etc., can solve the problems of unfavorable laser inversion, poor stability, and low threshold of resistance to photodamage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a method for preparing a mid-infrared thulium-holmium co-doped sesquioxide laser single crystal optical fiber described in the above technical solution, comprising the following steps:

[0030] (1) Dosing according to the chemical composition of the mid-infrared thulium-holmium co-doped sesquioxide laser single crystal optical fiber, and mixing each initial raw material to obtain a mixed raw material;

[0031] (2) Using the mixed raw materials in the step (1) to prepare a polycrystalline material rod;

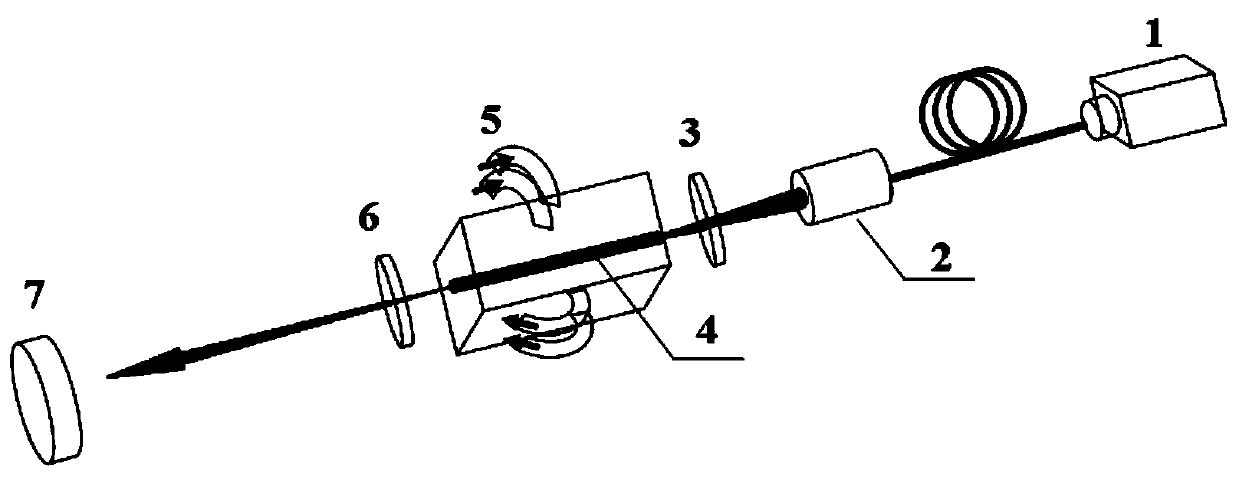

[0032] (3) A laser heating susceptor method is adopted to prepare a mid-infrared thulium-holmium co-doped sesquioxide laser single crystal optical fiber by using the polycrystalline material rod in the step (2).

[0033] The invention mixes ingredients according to the chemical composition of mid-infrared thulium-holmium co-doped sesquioxide laser single-crystal optical fiber, and mixes each initial raw material to obtain the mixed raw mate...

Embodiment 1

[0052] A method for preparing a mid-infrared thulium-holmium co-doped sesquioxide laser single crystal optical fiber, comprising the following steps:

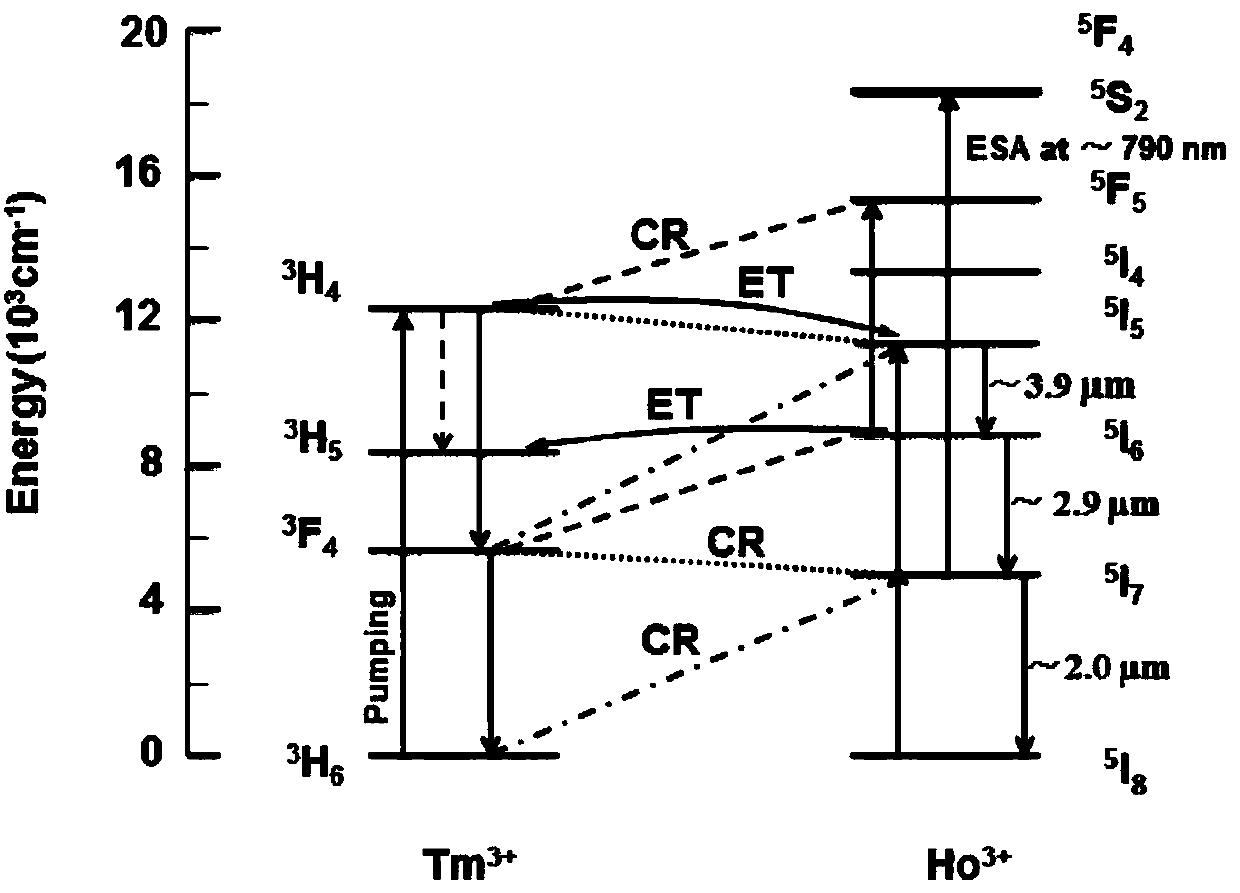

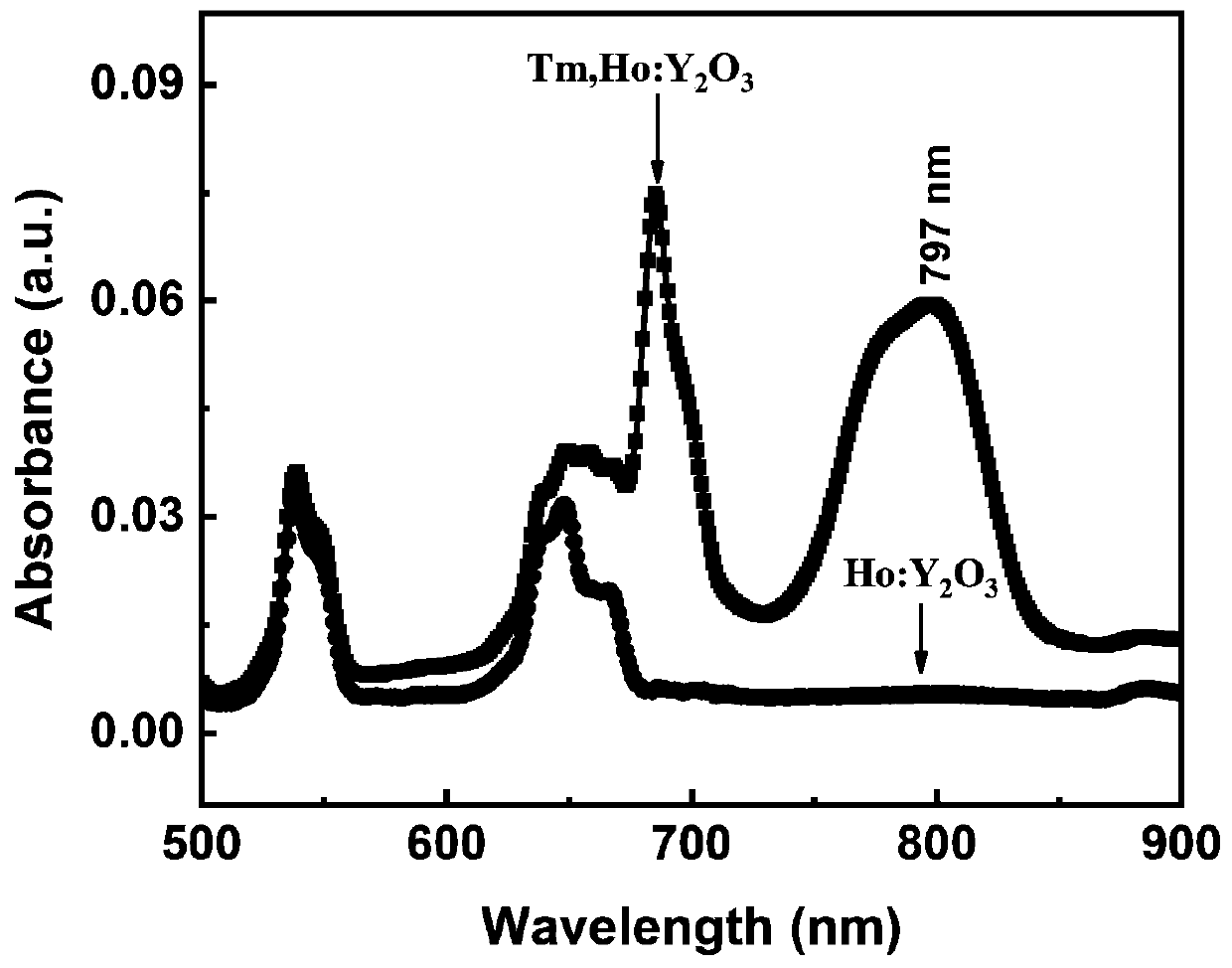

[0053] Will Tm 2 o 3 、Ho 2 o 3 and Y 2 o 3 Mix to get mixed raw materials; where, Tm 2 o 3 、Ho 2 o 3 and Y 2 o 3 The purity is not less than 99.99%, Tm 3+ The doping concentration is 1at%, Ho 3+ The doping concentration is 1.5at%;

[0054] The balloon is placed in a cylindrical mold with an inner diameter of 1.5 mm, the mixed raw materials are filled into the balloon, and compacted with a glass rod until the filling height reaches 15 cm, stop filling; the balloon is removed from the cylindrical mold After taking it out, vacuumize the mixed raw materials in the balloon, then put it vertically into a cold isostatic press, increase the pressure to 120MPa and keep the pressure for 2min, then remove the balloon to obtain a rod with uniform diameter;

[0055] The material rod was placed in a sintering furnace, and sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com