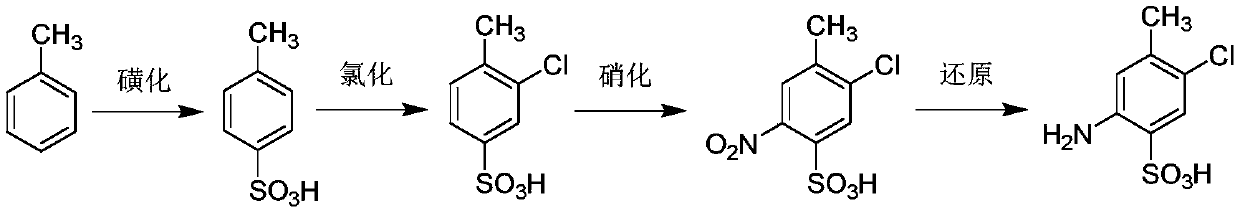

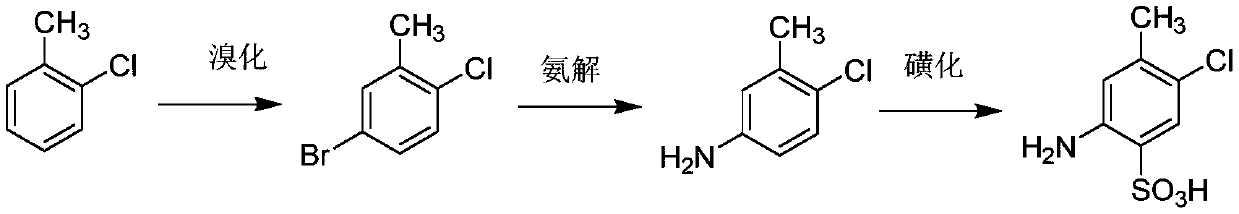

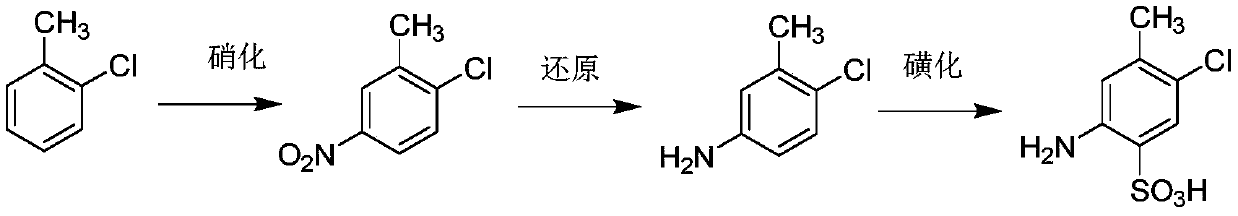

Method for preparing CLT acid by taking m-toluidine as raw material

A technology of toluidine and raw materials, applied in the field of preparing CLT acid, can solve the problems of low yield of salt-forming amino group, and achieve the effects of high yield, few by-products, and no dangerous process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Acylation operation steps: Add a magnetic stirrer in a 250mL three-necked flask, add m-toluidine (20.00g, 190.00mmol) under nitrogen protection at room temperature, and add acetic anhydride (20.60g ,171.54mmol), after the acetic anhydride was dropped, the temperature was raised to 85°C and stirred for about 1.0h, then the heating was stopped.

[0055] Reaction result: the content of m-acetamidotoluene was analyzed by HPLC to be >99%.

[0056] (2) Chlorination operation steps: Use an ice-water bath to cool down the acylation reaction solution. When the temperature drops to about 20°C, add 25mL of acetic acid and 44.08g (about 38.00mL) of concentrated hydrochloric acid to the acylation reaction solution. Use an ice-water bath to cool down to 15°C, use a constant pressure dropping funnel to add 22.22g of hydrogen peroxide dropwise within 60 minutes, keep stirring at 15-20°C for 2.5h after the hydrogen peroxide drops, then raise the temperature to 20-25°C and keep stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com