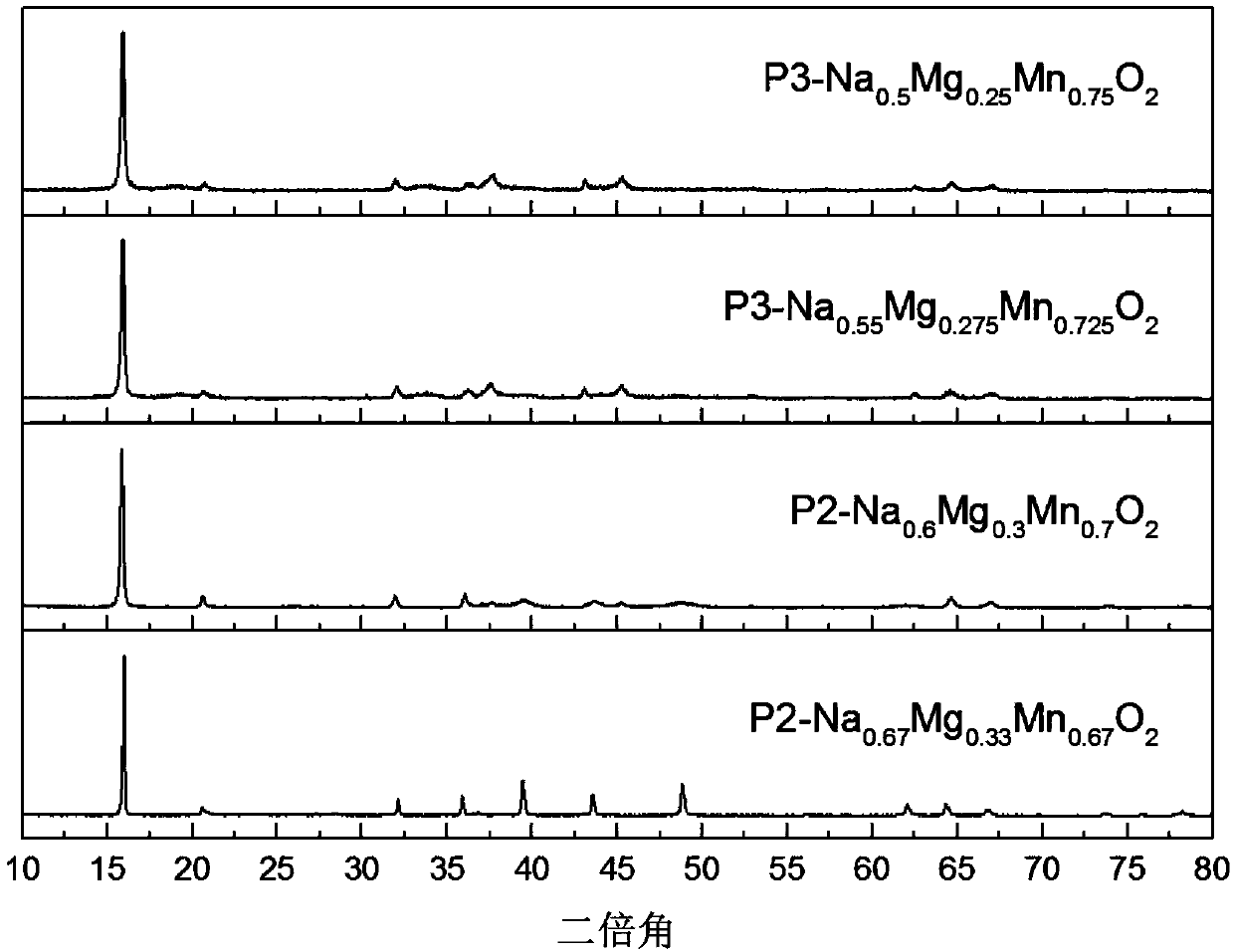

Sodium-magnesium-manganese-based layered oxide material having variable-valence anions, preparation method and use

A technology of oxides and anions, applied in the field of materials, to achieve the effects of high specific energy, simple material preparation, and high-quality specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The embodiment of the present invention provides a sodium-magnesium-manganese-based layered oxide material with variable anion valence, a preparation method and an application. The layered oxide material is easy to prepare, and the contained elements sodium, magnesium and manganese are all non-toxic and safe elements, and are abundant in the earth's crust, so the manufacturing cost is low. The sodium-ion secondary battery using the sodium-magnesium-manganese-based layered oxide material of the present invention has simple material preparation, and it is found in the half-cell test that the material not only has higher mass specific capacity and specific energy, but the specific capacity is equal to that of ordinary sodium It is 1.5 to 2 times that of the positive electrode material of ion batteries, and has a good cycle life. It has great practical value and can be used in large-scale energy storage equipment for solar power generation, wind power generation, smart grid ...

Embodiment 2

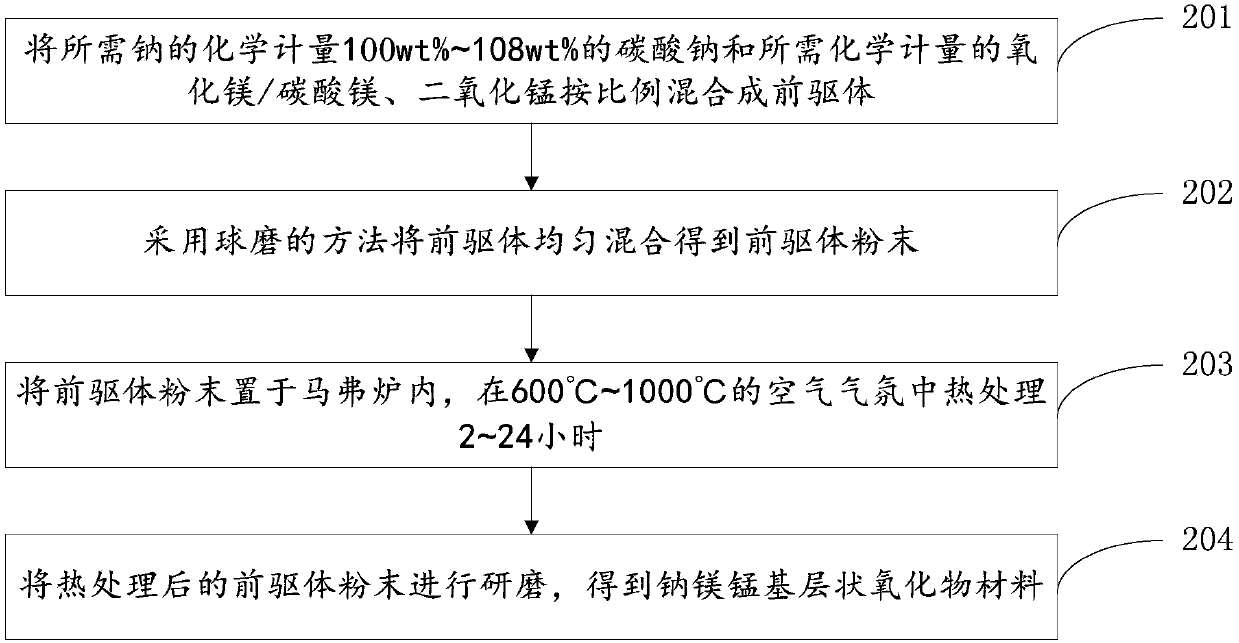

[0067] This embodiment provides a method for preparing a sodium-magnesium-manganese-based layered oxide material, specifically a solid-phase method, such as figure 2 shown, including:

[0068] Step 201, mixing sodium carbonate with a stoichiometric amount of required sodium of 100wt% to 108wt% and required stoichiometric magnesium oxide / magnesium carbonate and manganese dioxide in proportion to form a precursor;

[0069] Step 202, using a ball milling method to uniformly mix the precursor to obtain a precursor powder;

[0070] Step 203, placing the precursor powder in a muffle furnace, and heat-treating it in an air atmosphere at 600° C. to 1000° C. for 2 to 24 hours;

[0071] Step 204, grinding the heat-treated precursor powder to obtain a sodium-magnesium-manganese-based layered oxide material.

[0072] The preparation method of the sodium-magnesium-manganese-based layered oxide material provided in this embodiment can be used to prepare the sodium-magnesium-manganese-bas...

Embodiment 3

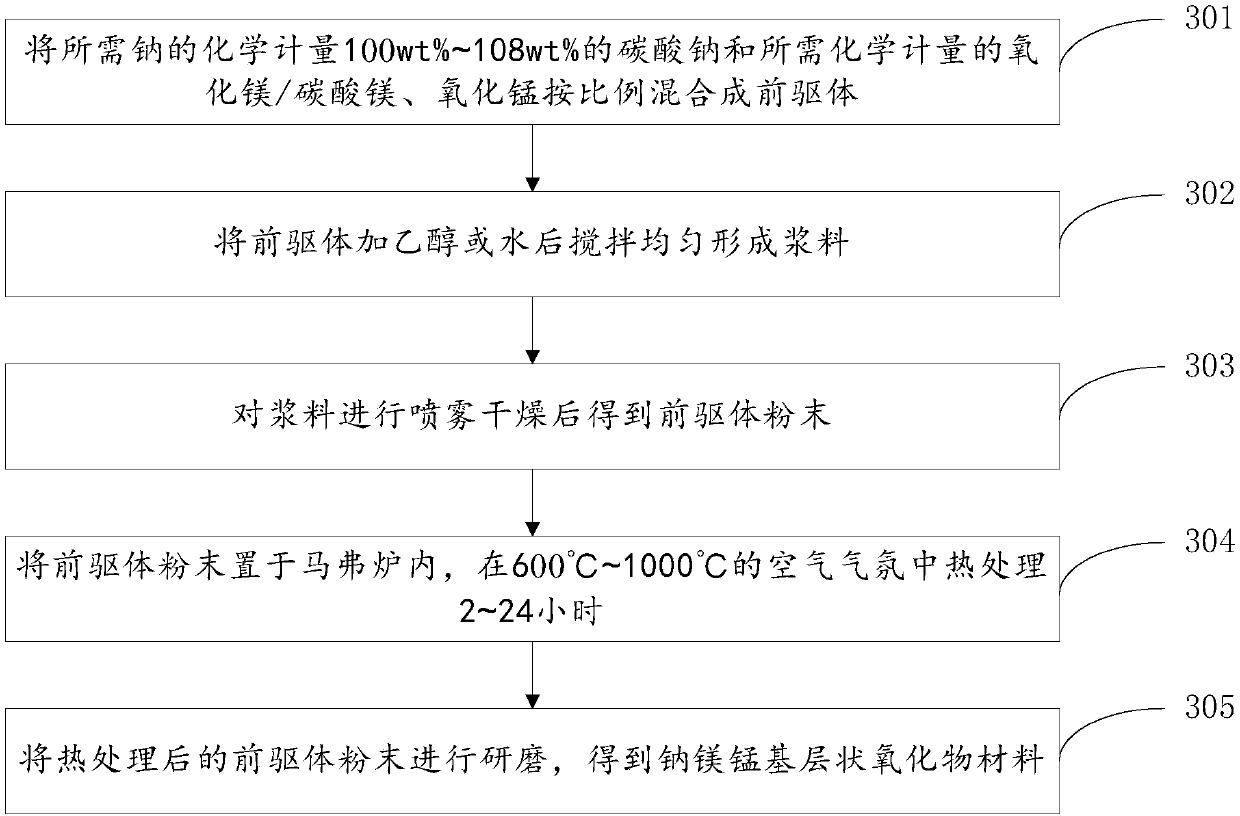

[0074] This embodiment provides a preparation method of a sodium-magnesium-manganese-based layered oxide material, specifically a spray drying method, such as image 3 shown, including:

[0075] Step 301, mixing sodium carbonate with a stoichiometric amount of required sodium of 100wt% to 108wt% and required stoichiometric magnesium oxide / magnesium carbonate and manganese oxide in proportion to form a precursor;

[0076] Step 302, adding ethanol or water to the precursor and stirring evenly to form a slurry;

[0077] Step 303, spray-drying the slurry to obtain a precursor powder;

[0078] Step 304, placing the precursor powder in a muffle furnace, and heat-treating in an air atmosphere at 600° C. to 1000° C. for 2 to 24 hours;

[0079] Step 305, grinding the heat-treated precursor powder to obtain a sodium-magnesium-manganese-based layered oxide material.

[0080] The preparation method of the sodium-magnesium-manganese-based layered oxide material provided in this embodime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com