Preparation method of nano 1T phase molybdenum disulfide/nickel disulfide composite nano material

A composite nanomaterial, molybdenum disulfide technology, applied in nickel sulfide, molybdenum sulfide, nanotechnology and other directions, can solve the problems of low purity, insufficient stability, low yield, etc., to achieve safe preparation process, maintain stability, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

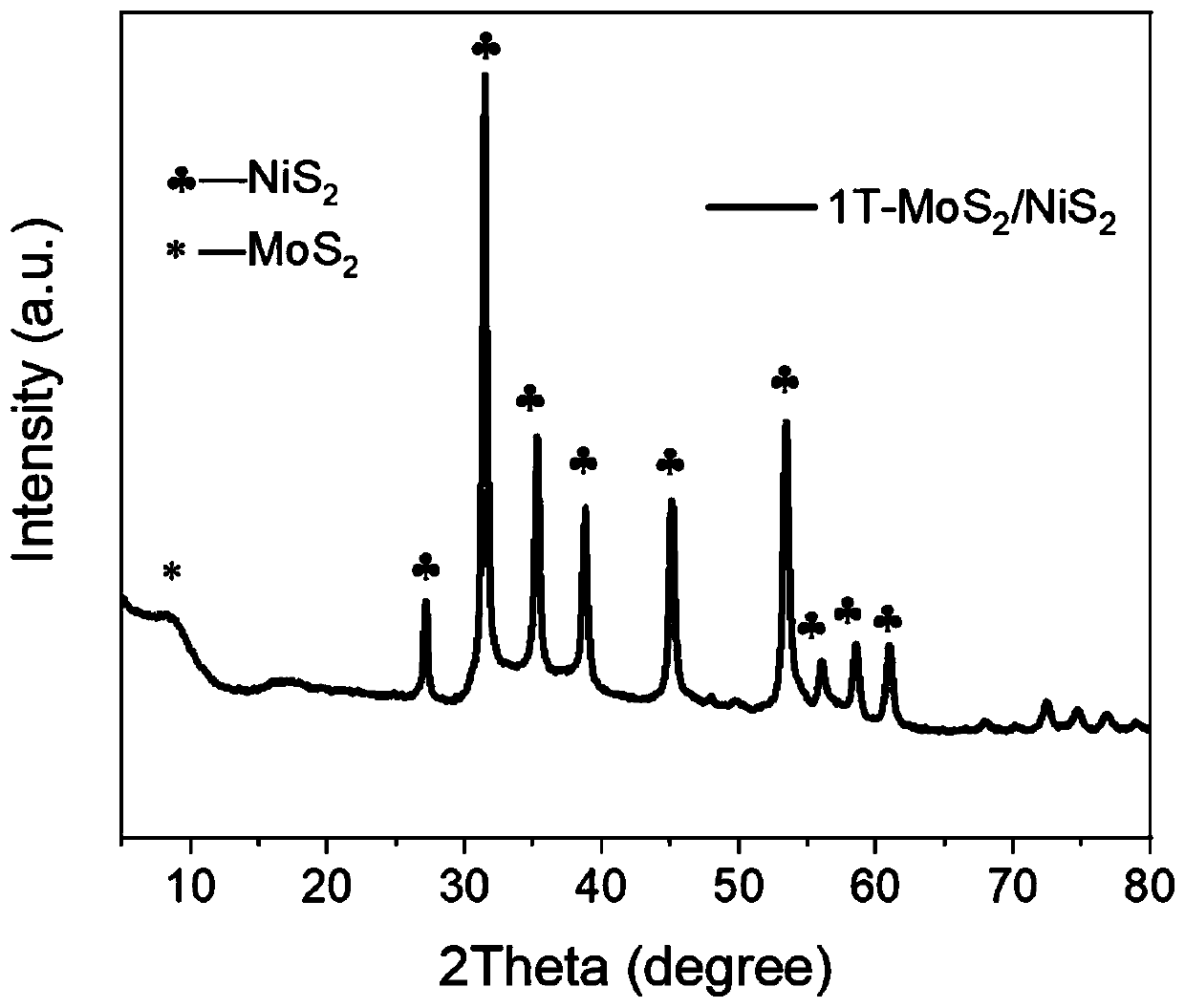

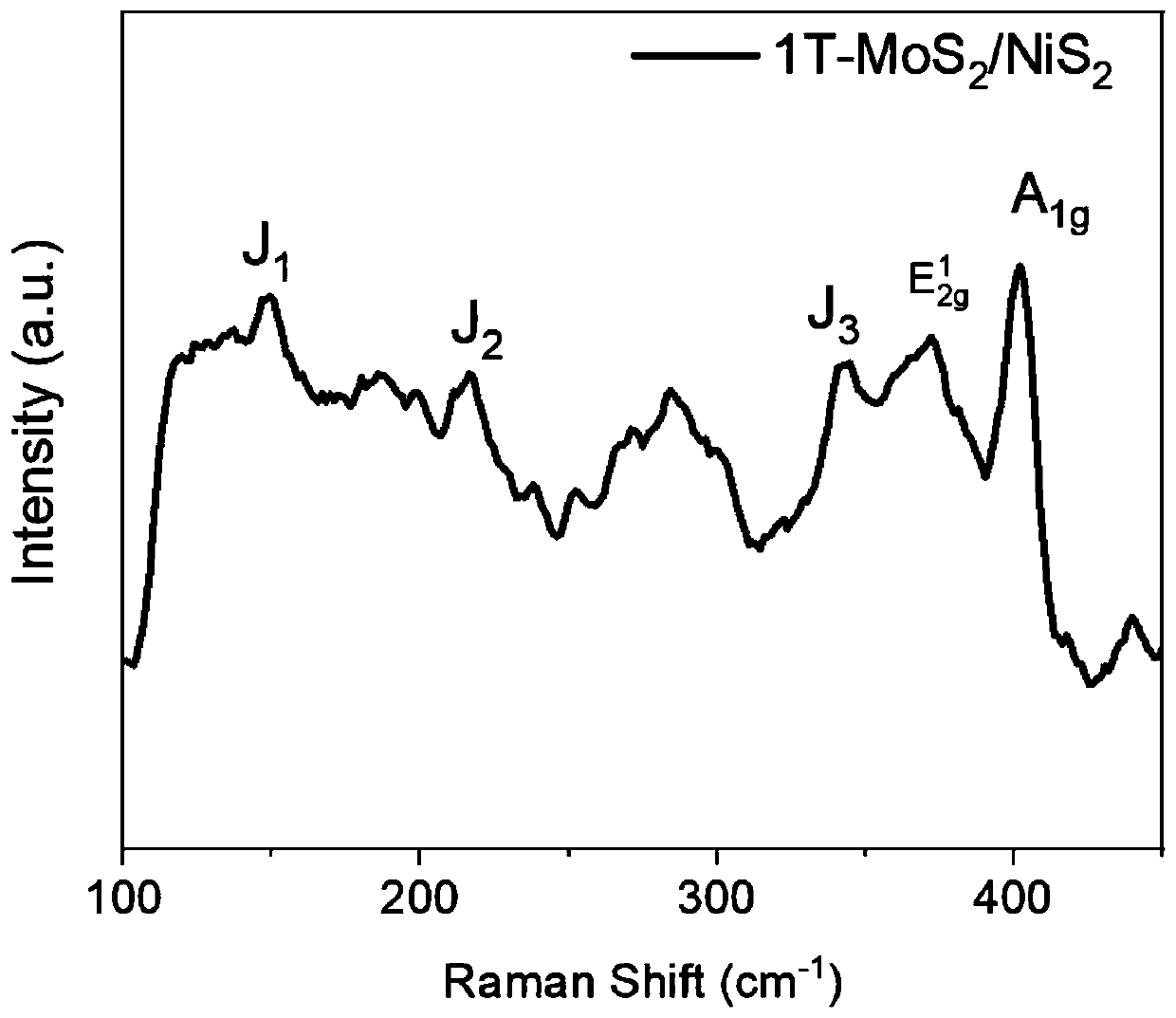

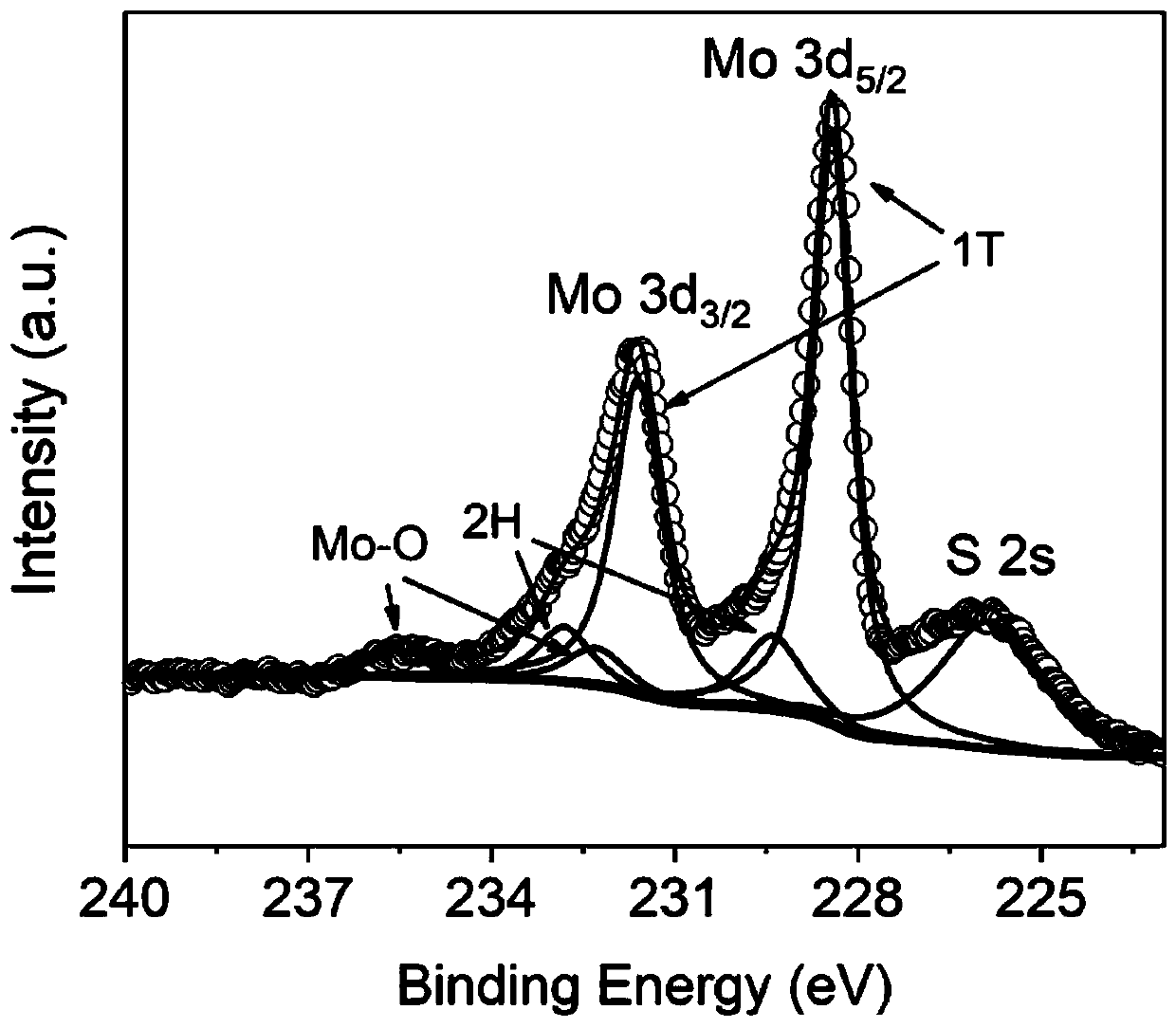

[0030] Put 0.581g of nickel nitrate, 1.68g of hexamethylenetetramine, 0.3g of ammonium molybdate and 0.02g of trisodium citrate dihydrate in 50mL of water, stir for half an hour to a light green transparent solution, pour into poly Store in a 100mL hydrothermal kettle lined with tetrafluoroethylene, seal and store, heat to 120°C, keep warm for 24h, and cool to room temperature, wash and centrifuge repeatedly with deionized water and absolute ethanol, and vacuum dry at 60°C for 12 hours to obtain Precursor (Ni(OH) 2-x -Mo 7 o 24 6- ); put 0.1g precursor and 2.0g thioacetamide into 35mL deionized water and stir vigorously for 1h, pour it into a 50mL polytetrafluoroethylene-lined hydrothermal kettle, keep it sealed, heat to 220°C, and keep it warm for 24h , cooled to room temperature, washed and centrifuged repeatedly with deionized water and absolute ethanol, and vacuum-dried at 60°C for 12 hours to obtain a 1T phase molybdenum disulfide / nickel disulfide composite. As shown ...

Embodiment 2

[0032] Put 0.581g of nickel nitrate, 1.68g of hexamethylenetetramine, 0.3g of ammonium molybdate and 0.02g of trisodium citrate dihydrate in 50mL of water, stir for half an hour to a light green transparent solution, pour into poly Store in a 100mL hydrothermal kettle lined with tetrafluoroethylene, seal and store, heat to 120°C, keep warm for 24h, and cool to room temperature, wash and centrifuge repeatedly with deionized water and absolute ethanol, and vacuum dry at 60°C for 12 hours to obtain Precursor (Ni(OH) 2-x -Mo 7 o 24 6- ); put 0.1g precursor and 2.0g thioacetamide into 35mL deionized water and stir vigorously for 1h, pour it into a 50mL polytetrafluoroethylene-lined hydrothermal kettle, keep it sealed, heat to 220°C, and keep it warm for 24h , cooled to room temperature, washed and centrifuged repeatedly with deionized water and absolute ethanol, and vacuum-dried at 60°C for 12 hours to obtain a 1T phase molybdenum disulfide / nickel disulfide composite.

Embodiment 3

[0034] Put 0.581g of nickel nitrate, 1.68g of hexamethylenetetramine, 0.1g of ammonium molybdate and 0.02g of trisodium citrate dihydrate in 50mL of water, stir for half an hour to a light green transparent solution, pour into poly Store in a 100mL hydrothermal kettle lined with tetrafluoroethylene, heat up to 120°C, keep warm for 20h, and cool to room temperature, wash and centrifuge repeatedly with deionized water and absolute ethanol, mix 0.1g of precursor with 2.0g of thio Put acetamide into 35mL deionized water and stir vigorously for 1h, pour it into a 50mL polytetrafluoroethylene-lined hydrothermal kettle, keep it sealed, heat to 220°C, keep it warm for 24h, cool to room temperature, and use deionized water and anhydrous Wash and centrifuge repeatedly with ethanol, and dry in vacuum at 60°C for 12 hours to obtain a 1T phase molybdenum disulfide / nickel disulfide composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com