A non-close-packed silica ring nanoarray and its preparation method

A technology of silica and nano-arrays, which is applied in the field of non-close-packed silica ring nano-arrays and its preparation, can solve the problems of poor mechanical strength and firmness of nanoparticles, high equipment requirements, complex processes, etc., and achieve mechanical strength And the effects of high firmness, low equipment requirements, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

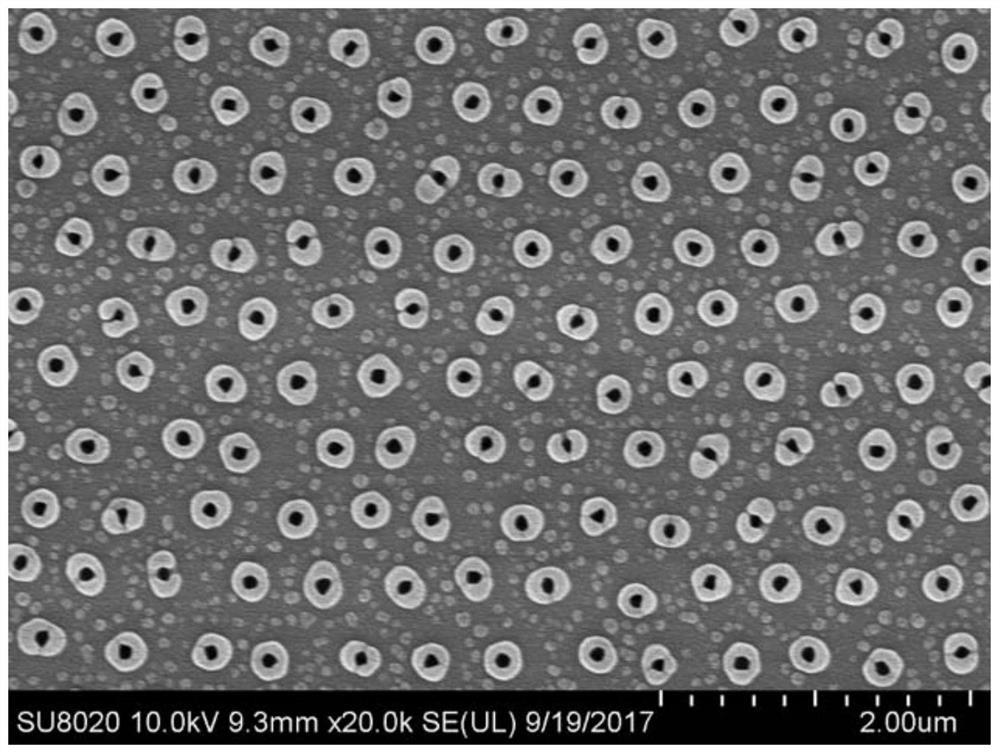

[0024] A method for preparing a non-close-packed silica ring nanoarray may comprise the following steps:

[0025] Step A, cleaning the quartz slices, drying the cleaned clean quartz slices, and then placing them in an ultraviolet ozone cleaner for 10-40 minutes of irradiation, so as to prepare clean quartz slices with a hydrophilic surface.

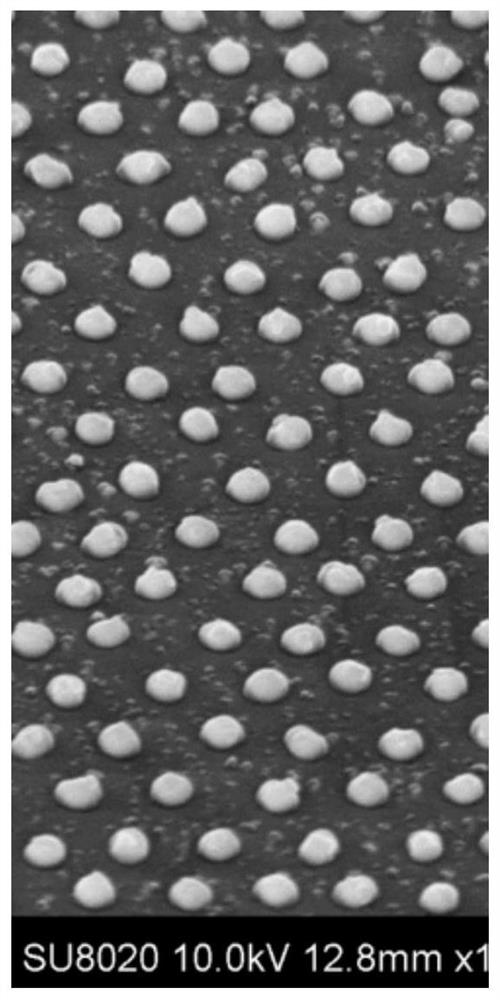

[0026] Step B, using a gas-liquid interface self-assembly method to prepare a tightly arranged single-layer polystyrene colloidal sphere array on the surface of the clean quartz sheet with a hydrophilic surface.

[0027] Step C, using the single-layer polystyrene colloidal sphere array on the quartz substrate as a template, and depositing a layer of silver film on the surface of the template by magnetron sputtering deposition method.

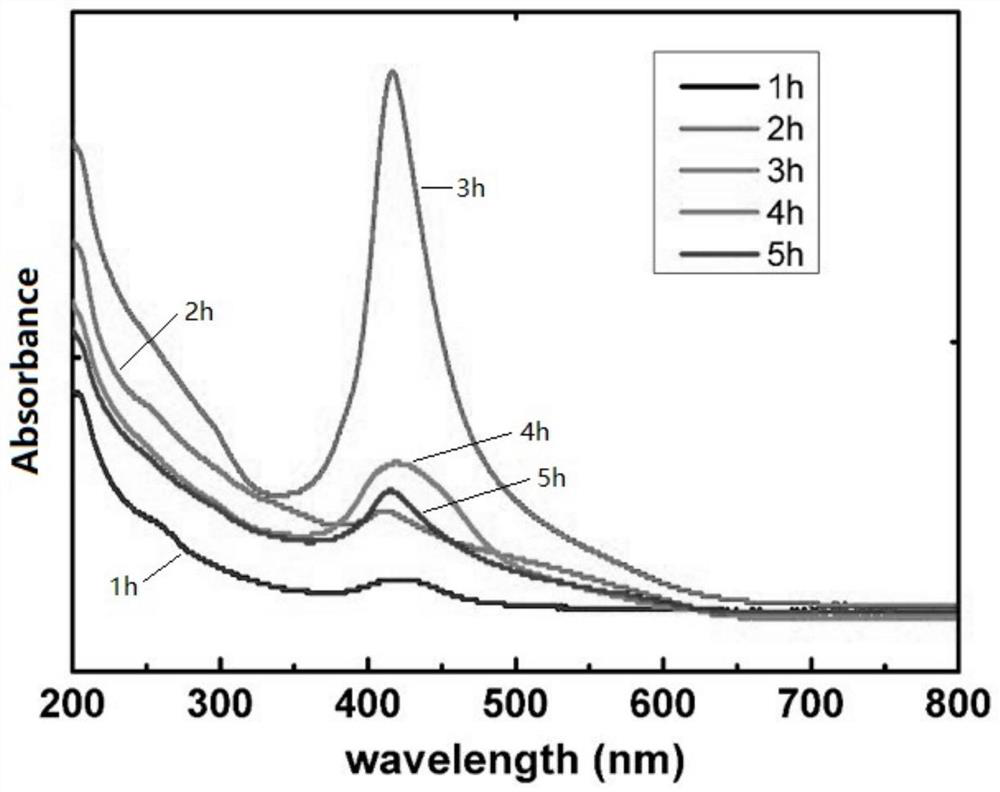

[0028] Step D, put the single-layer polystyrene colloidal ball array with the silver film deposited on the surface into a muffle furnace for heat treatment, set it for 170 minutes to increase from room temp...

Embodiment approach

[0031] (1) The cleaning of the quartz sheet includes: putting the quartz sheet into a cleaning container, adding acetone, alcohol and deionized water with a volume ratio of 1:1:1, covering with plastic wrap, and ultrasonic cleaning for 45 minutes; Then pour out the waste liquid in the cleaning container, and add concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 3:1, and ultrasonically clean it for 30 minutes after standing for 8 hours; then pour out the waste liquid in the cleaning container, and add a volume ratio of 3:1:1 deionized water, ammonia water and hydrogen peroxide, covered with plastic wrap, ultrasonically cleaned for 30 minutes; finally washed repeatedly with deionized water to obtain a clean quartz plate after cleaning.

[0032](2) Using the gas-liquid interface self-assembly method to prepare a tightly arranged single-layer polystyrene colloidal sphere array on the surface of the clean quartz sheet with a hydrophilic surface, comprising: tak...

Embodiment 1

[0040] Such as Figure 4 As shown, a method for preparing a non-close-packed silica ring nanoarray may comprise the following steps:

[0041] Step a, put the glass piece and quartz piece into a beaker, add acetone, alcohol and deionized water with a volume ratio of 1:1:1, cover with plastic wrap, and ultrasonically clean for 45 minutes; then pour the waste liquid in the beaker and add concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 3:1, and then ultrasonically clean it for 30 minutes after standing for 8 hours; pour out the waste liquid in the beaker, and add deionized water with a volume ratio of 3:1:1, Ammonia and hydrogen peroxide, covered with plastic wrap, ultrasonically cleaned for 30 minutes; finally, washed repeatedly with deionized water to obtain clean glass sheets and clean quartz sheets after cleaning. An oven is used to dry the cleaned clean glass sheet and clean quartz sheet, and then placed in an ultraviolet ozone cleaning machine for 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com