Feed for injection molding of zirconium oxide ceramic and preparation method thereof

A zirconia ceramic and injection molding technology, applied in the field of precision ceramic preparation, can solve the problems of poor sintering process controllability, high hardness of zirconia ceramics, and high organic content, so as to solve the hidden dangers of environmental protection and safety, good flow performance, and expand application fields Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Batching by mass percentage, get 85wt% ZrO(OH) 2 Precursors, 10wt% polyvinylpyrrolidone PVP and 5wt% stearic acid are added to the mixer at 180°C to melt and stir, and after fully mixing, cool down and set aside to obtain an organic mixture. The following steps are used to prepare a low-distortion, High precision zirconia ceramic material:

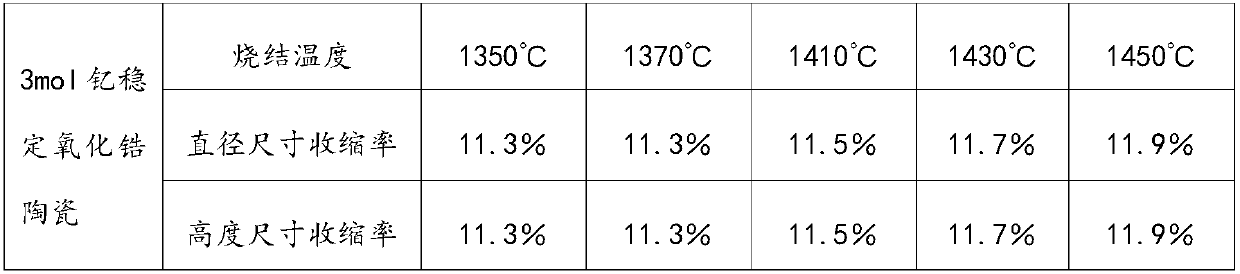

[0038] (1) Put 3mol yttrium-stabilized zirconia powder into a 200KG horizontal ceramic ball mill for ball milling for 16 hours, and spray granulation after ball milling;

[0039] (2) Put the yttrium-stabilized zirconia powder after spray granulation into a mixer, add an organic mixture with a powder mass fraction of 12 wt%, and uniformly mix at a temperature of 180° C.;

[0040] (3) After the mixed raw materials are granulated into a ceramic feed with a diameter of 3 mm and a height of 5 mm in a granulator, the feed is sent into the hopper of a high-pressure injection molding machine through an automatic feeder, and the injection p...

Embodiment 2

[0046] Batching by mass percentage, get 82wt% ZrO(OH) 2 Precursor, 8wt% high-density polyethylene HDPE, 5wt% polypropylene PP and 5wt% stearic acid are added to the mixer at 180°C to melt and stir, and after fully mixing, cool and set aside to obtain an organic mixture. The low deformation and high precision zirconia ceramic material is prepared through the following steps:

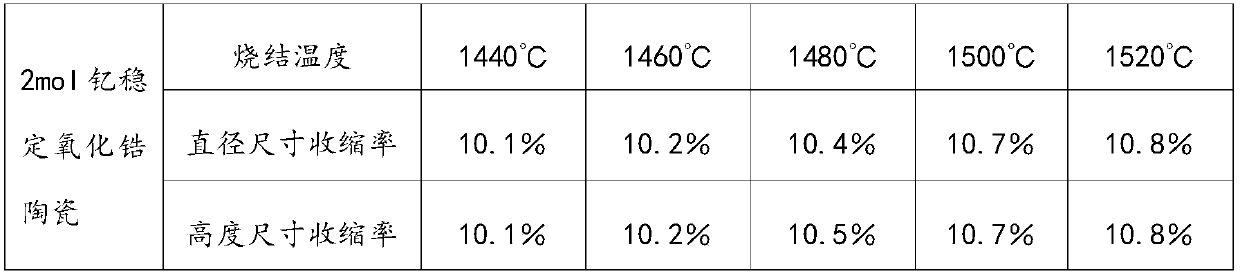

[0047] (1) After 2mol yttrium-stabilized zirconia powder (2YSZ) is batched, put into a 200KG horizontal ceramic ball mill for ball milling for 16 hours, and spray granulate after ball milling;

[0048] (2) Put the zirconia powder after spray granulation into the kneader, add an organic mixture with a powder mass fraction of 12%~, and knead evenly at a temperature of 180°C;

[0049] (3) After the mixed raw materials are granulated into a ceramic feed with a diameter of 3 mm and a height of 5 mm in a granulator, the feed is sent into the hopper of a high-pressure injection molding machine through an automa...

Embodiment 3

[0055] The same features of this embodiment as those of Embodiment 1 or Embodiment 2 will not be repeated here. The difference between this embodiment and the above-mentioned embodiment is that the ingredients are formulated according to mass percentage, and 75wt% of ZrO(OH) is taken. 2 Precursor, at least one of 20wt% high-density polyethylene HDPE, ethylene-vinyl acetate copolymer EVA, polyvinylpyrrolidone PVP, polyvinyl butyral PVB, random polypropylene APP, polypropylene PP, and At least one of 5 wt% of stearic acid SA, oleic acid OA, and carboxystearic acid HSA is added into a mixer and melted at 160°C.

[0056] The ball milling time in (1) was 5 hours, and the kneading temperature was 130°C.

[0057] (2) Add an organic compound with a powder mass fraction of 12 wt%, and knead evenly at a temperature of 130°C.

[0058] (3) The injection pressure is 20MPa, and the injection temperature is 125°C.

[0059] (4) The ceramic blank in the middle is subjected to degreasing trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com