Tackifier for oil-based drilling fluid and preparation method thereof

A technology of oil-based drilling fluid and viscosity raising agent, applied in chemical instruments and methods, drilling compositions, inorganic chemistry, etc., can solve the problem of increasing organic soil, oil-based drilling fluid fluid loss control polymer and other materials Increased amount, water-based drilling fluid viscosifier is not suitable for oil-based drilling fluid, oil-based drilling fluid environmental protection needs to be improved, etc., to improve the colloidal stability of the dispersion system, strong chemical activity and physical adsorption performance, strong chemical activity and physical adsorption sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

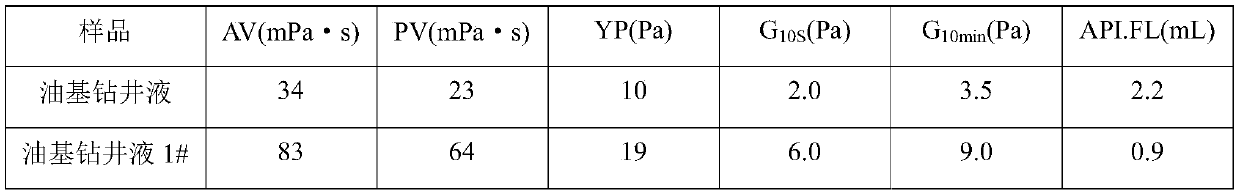

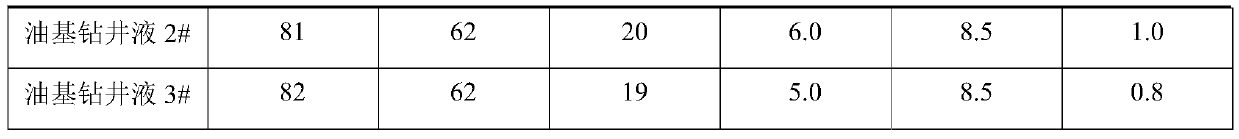

Examples

Embodiment 1

[0027] Example 1: Preparation of modified organic soil

[0028] The organic clay used in the present invention may be bentonite, montmorillonite, attapulgite, etc. Among them, bentonite has good swelling, adsorption, cation exchange and large internal and external specific surface area, and can carry out interlayer compounding or insertion reaction with many guest substances, so it is widely used in chemical industry, petroleum, food, transportation , Medicine, papermaking, energy, military, environmental protection and other industries are called "universal materials". The activation modification method is to activate the bentonite. The commonly used methods include acidification, roasting, salt activation, microwave activation, reduction, and oxidation. In the present invention, the acidification method is adopted to modify the bentonite, and at the same time, the dispersibility of the modified bentonite can be improved, which specifically includes the following steps:

[0029]...

Embodiment 2

[0032] Example 2: Preparation of modified vegetable gum

[0033] Guar gum (GUM) comes from the endosperm of the herb guar. It is a natural green product with special physical and chemical properties. It can be used as a thickener, stabilizer, emulsifier, dispersing and suspending agent, water-retaining agent and Gel agent, its application involves oil field, papermaking, medicine, daily necessities, food, textile, water treatment, mining explosives and other fields. Guar gum is a linear galactomannan, which is a non-ionic polymer. Although guar gum has good water solubility and thickening properties, the raw powder still has the following shortcomings: it cannot quickly swell and hydrate, the dissolution rate is slow, and the content of water-insoluble matter is high. These shortcomings greatly limit the application of guar gum, so it needs to be chemically modified. In the present invention, the hydroxypropyl modification method is used to modify the guar gum, specifically:

[...

Embodiment 3

[0037] Example 3: Preparation of viscosity-lifting agent for oil-based drilling fluid

[0038] 1. Raw material preparation

[0039] Modified organic clay: activated modified bentonite, montmorillonite, attapulgite, etc. can be used. In the present invention, bentonite modified by acidification and improved dispersion is preferred (Example 1);

[0040] Modified vegetable gum: hydroxypropyl guar gum prepared in preferred embodiment 2 of the present invention;

[0041] Thermoplastic elastic resin: can be from polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), polyamide (PA), polyoxymethylene (POM), polycarbonate (PC) , Polyphenylene ether, polysulfone, rubber, etc.;

[0042] acrylic acid;

[0043] Hydroxymethyl cellulose;

[0044] Quaternary ammonium salt: The quaternary ammonium salt in the present invention is preferably methacryloxyethyl trimethylammonium chloride.

[0045] Emulsifier: The emulsifier in the present invention is preferably a water-in-oil W / O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com