Multi-element doped graphene fibers and preparation and application thereof

A graphene fiber and multi-element technology, applied in graphene, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of large demand for doping sources, complicated process, high cost, etc., and achieve simplified preparation process and excellent flexibility , the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a kind of preparation method of the graphene fiber of multi-element doping, comprises the steps:

[0043] (1) the graphene oxide solution is injected into the coagulation bath with the method of wet spinning, the graphene oxide is gelled and separated out to obtain graphene oxide fibers, and the coagulation bath is an aqueous solution of an ionic liquid;

[0044] (2) reducing the graphene oxide fiber obtained in step (1), reducing the oxygen-containing functional group on the surface of the graphene oxide, and obtaining the graphene fiber after drying;

[0045] (3) Calcining the graphene fibers obtained in step (2) under an inert atmosphere, so that the graphene fibers are carbonized to obtain multi-element doped one-dimensional porous graphene fibers.

[0046]In order to coagulate and precipitate into fibers in the coagulation bath, the concentration of graphene oxide in the graphene oxide solution described in step (1) needs to reach a certain c...

Embodiment 1

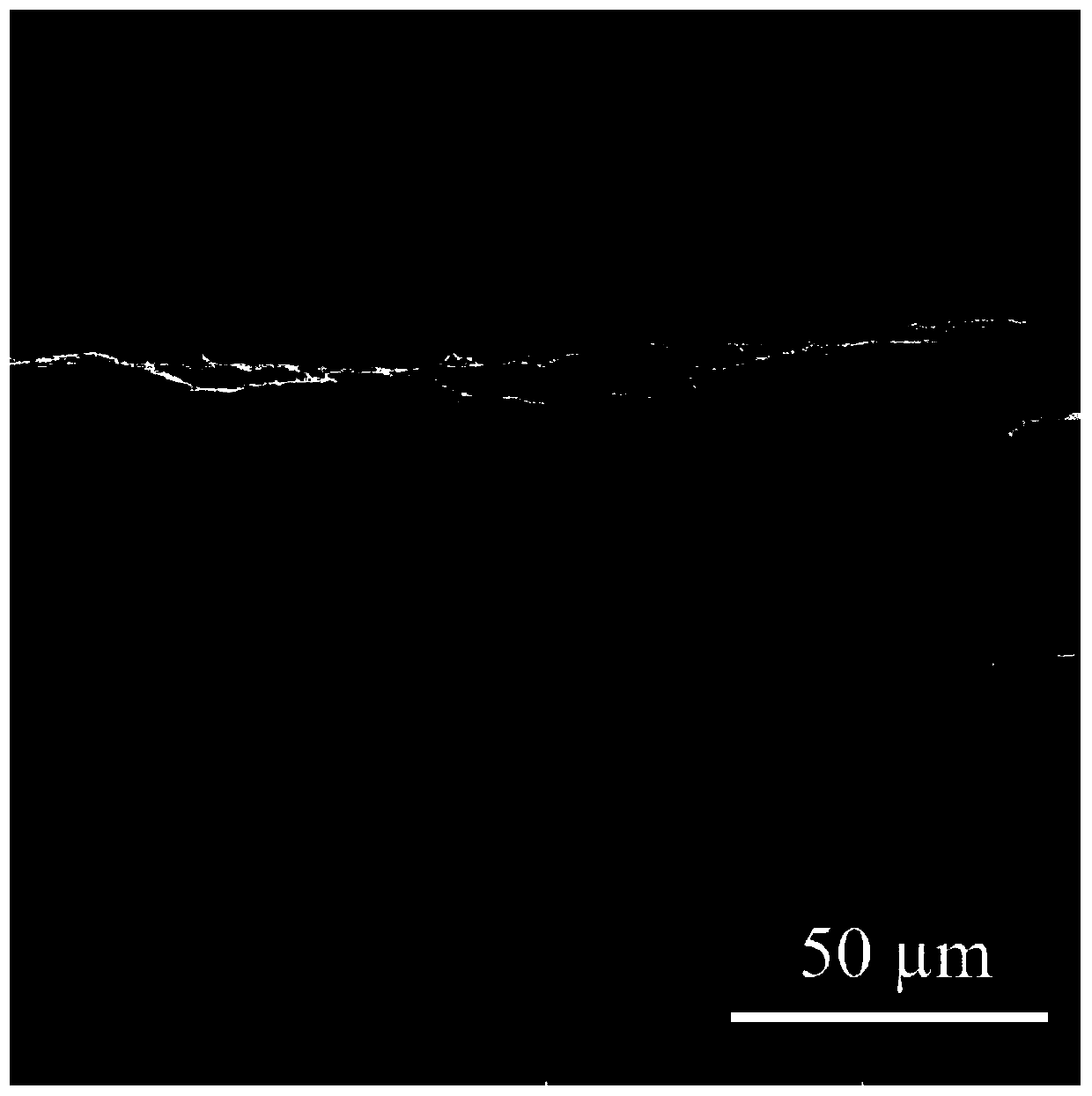

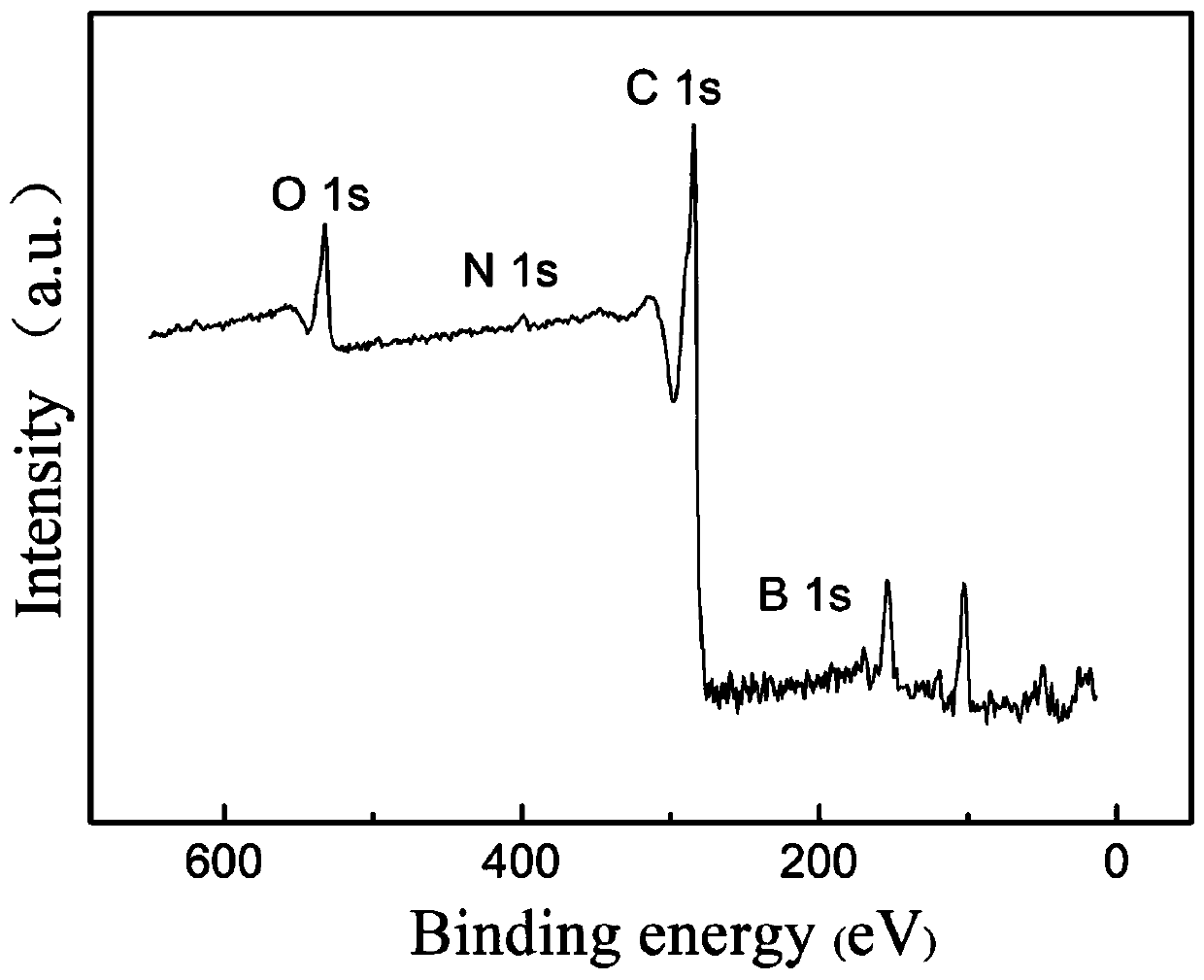

[0071] Stir 5 g of expanded graphite in 270 ml of concentrated sulfuric acid (98%) for 2 hours, then slowly add 6 g of potassium permanganate to the solution, keep the reaction temperature below 5°C during this process, stir for 1 h to disperse evenly. Then the above was heated to 50° C. for 12 h to obtain a graphene oxide (GO) solution containing impurities. The reaction was introduced into a mixture of ice and water, and hydrogen peroxide was added until it became bright yellow. Add dilute hydrochloric acid aqueous solution to wash to ensure that the homogeneous phase of the system does not condense, and repeatedly centrifuge with deionized water until neutral to obtain a graphene oxide solution. The GO solution with a concentration of 20 mg / mL obtained by centrifugation was injected into a 6 mg / L ion solution by wet spinning, reduced with HI acid and freeze-dried. It was placed in an inert gas atmosphere and reacted in a tube furnace at 900 degrees Celsius for 2 hours, and...

Embodiment 2

[0077] Stir 5 g of expanded graphite in 270 ml of concentrated sulfuric acid (98%) for 2 hours, then slowly add 6 g of potassium permanganate to the solution, keep the reaction temperature below 5°C during this process, stir for 1 h to disperse evenly. Then the above was heated to 50° C. for 12 h to obtain a graphene oxide (GO) solution containing impurities. The reaction was introduced into a mixture of ice and water, and hydrogen peroxide was added until it became bright yellow. Add dilute hydrochloric acid aqueous solution to wash to ensure that the homogeneous phase of the system does not condense, and repeatedly centrifuge with deionized water until neutral to obtain a graphene oxide solution. The GO solution with a concentration of 12 mg / mL obtained by centrifugation was injected into a 6 mg / L ion solution by wet spinning, and then freeze-dried after reduction with HI acid. It was placed in an inert gas atmosphere and reacted in a tube furnace at 800 degrees Celsius for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com