Preparation method of isotropic graphite material

A graphite material and isotropic technology, which is applied in the field of preparation of isotropic graphite materials, can solve the problems of large-area cracking, poor mechanical properties, and high porosity of products, and achieve stable product quality, excellent performance, and improved compactness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

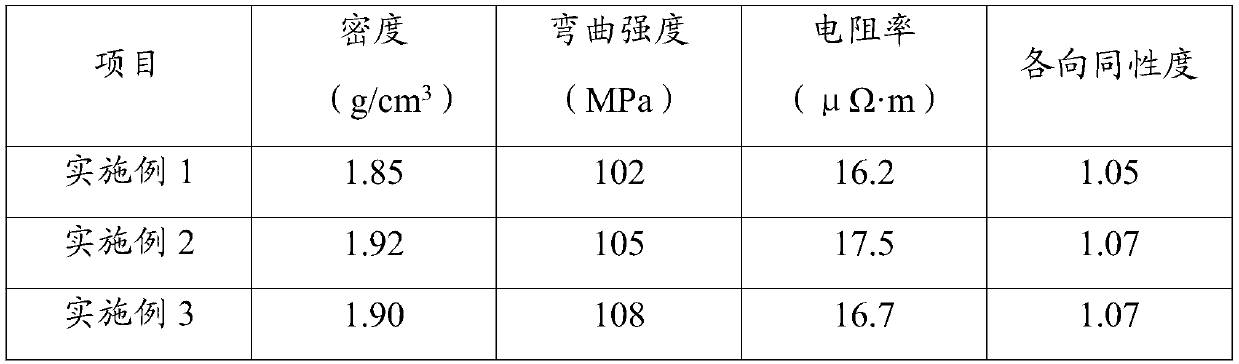

Embodiment 1

[0038] A preparation method of isotropic graphite material, comprising the following steps:

[0039] ①Sieving mesophase carbon microspheres after crushing to obtain mesophase carbon microsphere granulation powders with different particle sizes;

[0040] ②Crush the chopped carbon fiber and pass through a 400-mesh sieve to obtain the chopped carbon fiber granulated powder;

[0041] ③The mesophase carbon microsphere granulation powder and chopped carbon fiber granulation powder with 20wt% particle size of 5-10μm, 35wt% particle size of 20-30μm, and 45wt% particle size of 40-50μm were subjected to liquid phase dispersion method Doping and mixing modification with wet ball milling. The dispersant used in the liquid phase dispersion method is sodium dodecylbenzenesulfonate. When wet ball milling, ball: material: water = 2.5:1:0.8, mesophase carbon microspheres The mass ratio of the granulated powder and the chopped carbon fiber granulated powder is 95:5 to obtain a modified mesopha...

Embodiment 2

[0048] A preparation method of isotropic graphite material, comprising the following steps:

[0049] ①Sieving mesophase carbon microspheres after crushing to obtain mesophase carbon microsphere granulation powders with different particle sizes;

[0050] ②Crush the chopped carbon fiber and pass through a 600-mesh sieve to obtain the chopped carbon fiber granulated powder;

[0051]③ 38wt% of mesophase carbon microsphere granulation powder and chopped carbon fiber granulation powder with particle size of 5-10 μm, 22wt% of particle size of 20-30 μm, and 40wt% of particle size of 40-50 μm were subjected to liquid phase dispersion and Wet ball milling is used for doping and mixing modification. The dispersant used in the liquid phase dispersion method is sodium dodecylbenzenesulfonate. Ball: material: water = 3:1:0.8 during wet ball milling, mesophase carbon microspheres The mass ratio of granular powder and chopped carbon fiber granulated powder is 98:2, obtains modified mesophase...

Embodiment 3

[0058] A preparation method of isotropic graphite material, comprising the following steps:

[0059] ①Sieving mesophase carbon microspheres after crushing to obtain mesophase carbon microsphere granulation powders with different particle sizes;

[0060] ②Crush the chopped carbon fiber and pass through a 500-mesh sieve to obtain chopped carbon fiber granulation powder;

[0061] ③The mesophase carbon microsphere granulation powder and chopped carbon fiber granulation powder with 35wt% particle size of 5-10 μm, 15wt% particle size of 20-30 μm, and 50wt% particle size of 40-50 μm were subjected to liquid phase dispersion and Wet ball milling is used for doping and mixing modification. The dispersant used in the liquid phase dispersion method is sodium dodecylbenzenesulfonate. During wet ball milling, ball: material: water = 2.8:1:0.8, mesophase carbon microspheres The mass ratio of granular powder and chopped carbon fiber granulated powder is 90:10, obtains modified mesophase car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com