Universal method for preparing hierarchical pore coexisting heteroatom doped carbon catalyst by using soft template agent, and applications of hierarchical pore coexisting heteroatom doped carbon catalyst

A technology of soft template agent and carbon catalyst, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., to achieve the effects of increasing specific surface area, environmental friendliness, and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step S1: Grinding 1 g of Tachibana biomass in a glass mortar for 20 minutes to obtain material A1;

[0032] Step S2: Transfer material A1 to a nickel boat and place it in a tube furnace. In a nitrogen atmosphere with a flow rate of 100mL / min, first raise the temperature from room temperature to 330°C for 60 minutes and keep it for 120 minutes, and then increase the temperature at a rate of 3°C / min. Raise the temperature to 800°C and keep it for 120min, then naturally cool to room temperature to obtain material B1;

[0033] Step S3: Wash material B1 with 2M hydrochloric acid solution for 2-3 times and dry at 105°C for 12 hours to obtain the target product carbon catalyst C1, which is used as the cathode catalyst of the electro-Fenton degradation system to degrade 50mL of 10mg / L The degradation efficiency of methylene yellow solution was 65% after 60 minutes, and the time used for complete degradation was 120 minutes.

Embodiment 2

[0035] Step S1: Mix 1g of biomass Tachibana vine and 2g of soft templating agent C 10 h 18 K 2 N 2 o 10 Place in a glass mortar and grind for 20 minutes to obtain material A1;

[0036] Step S2: Transfer material A2 to a nickel boat and place it in a tube furnace. In a nitrogen atmosphere with a flow rate of 100mL / min, first raise the temperature from room temperature to 330°C for 60 minutes and keep it for 120 minutes, and then increase the temperature at a rate of 3°C / min. Raise the temperature to 800°C and keep it for 120min, then naturally cool to room temperature to obtain material B2;

[0037] Step S3: Wash material B2 with 2M hydrochloric acid solution for 2-3 times and dry at 105°C for 12 hours to obtain the target product carbon catalyst C2, which is used as the cathode catalyst of the electro-Fenton degradation system to degrade 50mL of 10mg / L The degradation efficiency of methylene yellow solution was 74% after 60 minutes, and the time used for complete degradat...

Embodiment 3

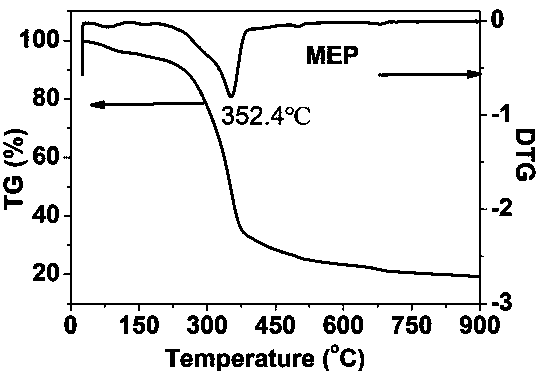

[0039] Step S1: Mix 1g of biomass Tachibana vine, 2g of soft templating agent C 10 h 18 K 2 N 2 o 10 and 0.5g dopant sodium hypophosphite were placed in a glass mortar and ground for 20 minutes to make it fully mixed to obtain material A3;

[0040] Step S2: Transfer material A3 to a nickel boat and place it in a tube furnace. In a nitrogen atmosphere with a flow rate of 100mL / min, first raise the temperature from room temperature to 330°C for 60 minutes and keep it for 120 minutes, and then increase the temperature at a rate of 3°C / min. Raise the temperature to 800°C and keep it for 120min, then naturally cool to room temperature to obtain material B3;

[0041] Step S3: Wash material B3 with 2M hydrochloric acid solution for 2-3 times and dry at 105°C for 12 hours to obtain the target product, phosphorus-doped carbon catalyst C3 with high electronegativity, which is used for electro-Fenton degradation The cathode catalyst of the system degrades 50mL of methylene yellow so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com