Eugenol surfactant and application thereof

A technology of reaction and compound, applied in the field of eugenol surfactant and its application, can solve the problems of poor biodegradability and carcinogenicity of degradation products, and achieve the effects of good water solubility, wide application prospect and simple synthetic route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

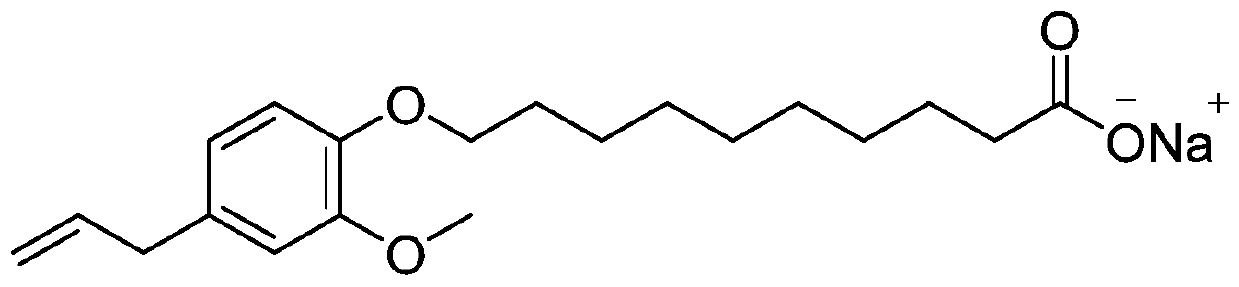

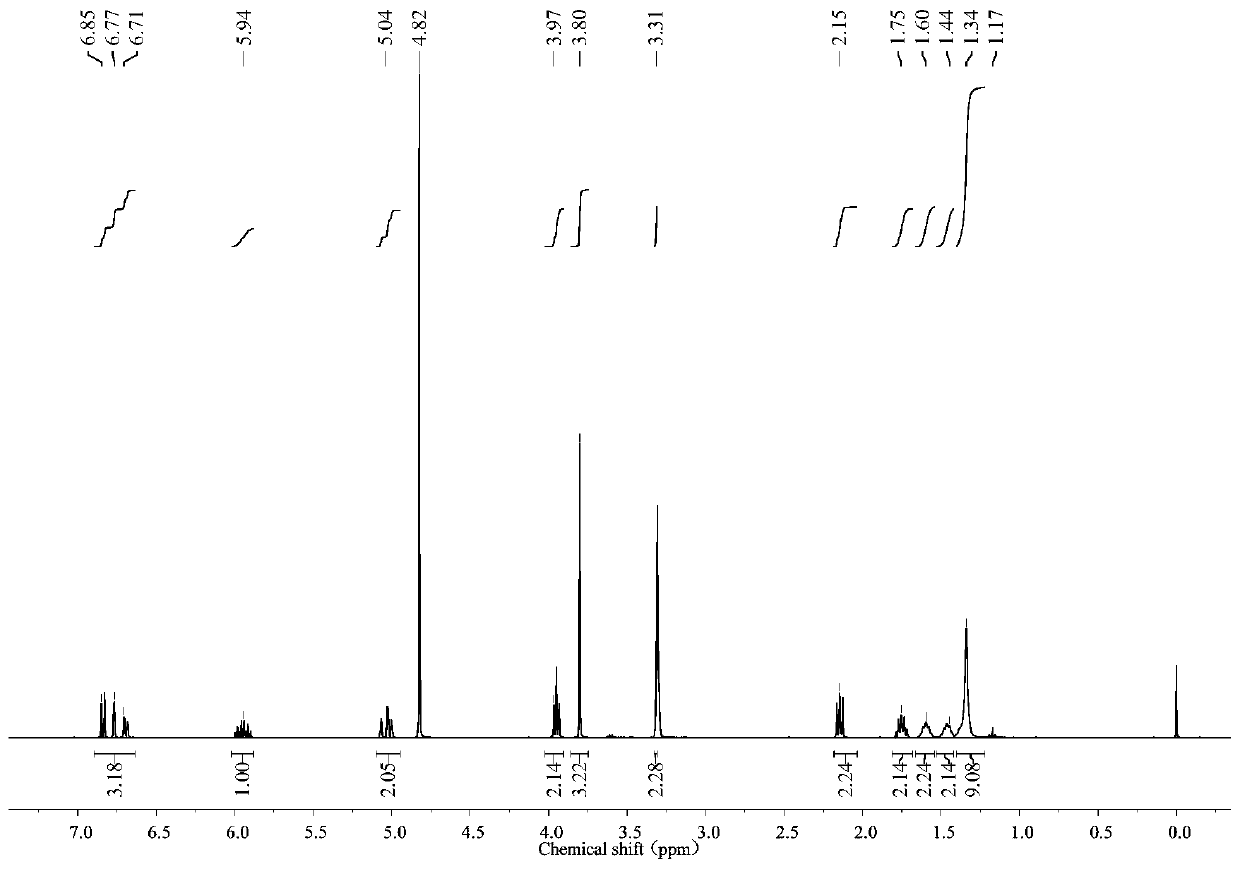

[0031] Example 1: Synthesis of eugenol surfactant 10-(4-allyl-2-methoxyphenoxy)sodium caprate.

[0032] Under nitrogen protection, 20 g of anhydrous potassium carbonate and 100 ml of acetone were added to a three-neck flask equipped with a magnetic stirrer, stirred for half an hour, and then 17 g of eugenol in acetone was added. After heating up to 60°C, add 14g of methyl 10-bromodecanoate in acetone solution, and react at 60°C for 72h. After the reaction, the product was cooled to room temperature, filtered with suction and the filtrate was collected, diluted with petroleum ether, then washed with deionized water, 50 mL saturated aqueous sodium bicarbonate solution and deionized water respectively, and the organic phase was dried with anhydrous magnesium sulfate. The solvent was removed by rotary evaporation to give methyl 10-(4-allyl-2-methoxyphenoxy)decanoate. Add methyl 10-(4-allyl-2-methoxyphenoxy)decanoate, sodium hydroxide, deionized water and absolute ethanol into a o...

Embodiment 2

[0033] Embodiment 2: Aggregation ability and emulsion stability of eugenol surfactant

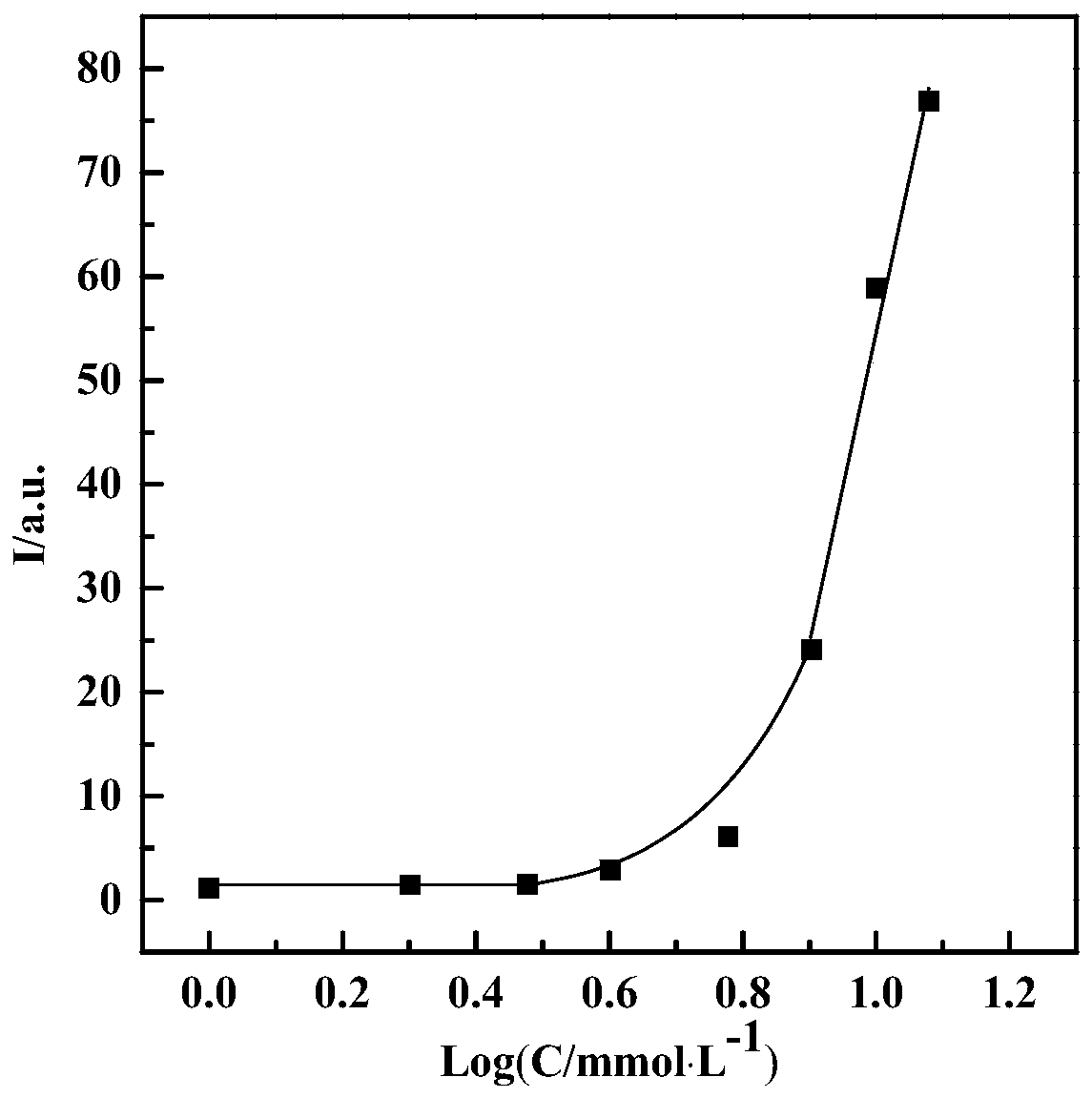

[0034] Prepare 1.0mmol·L -1 NR methanol solution, use a pipette gun to pipette 20 μL of NR solution into a 25mL columnar sample bottle, and use N 2 Dry the methanol in the bottle, and prepare 8 mL series of eugenol surfactant solutions with different concentrations. Under the constant temperature condition of 25°C, the samples were sonicated for 2 hours, and then shaken for 24 hours, and then the fluorescence spectra of each solution were measured with a CARY Eclipse fluorescence spectrometer. Set the excitation wavelength to 540nm, the scanning range to 550-750nm, both the excitation slit and the emission slit to 5nm, and the scanning speed to 250nm·min -1 . image 3 It is the curve graph of the fluorescence intensity of Nile Red with the concentration of eugenol surfactant aqueous solution, from image 3 It can be seen that the cmc of the surfactant is 3.9mM, showing better aggregatio...

Embodiment 3

[0035] Embodiment 3: Copolymerization of eugenol surfactant and styrene to obtain polystyrene nanospheres

[0036] In a cylindrical glass bottle with a volume of 25mL, weigh 4mmol·L -110ml of the eugenol surfactant solution, pipette 1ml of the oil phase styrene into the surfactant aqueous solution, homogenize and emulsify for 2min with the IKAULTRA-TURRAXT18basic homogenizer, the rotation speed is 11000rpm, and make a polystyrene emulsion; Stir the polystyrene emulsion at room temperature for 30 minutes, then raise the temperature to 80°C and add 20 μL of 0.5‰ potassium persulfate aqueous solution, and react the whole system in a constant temperature water bath at 80°C for 12 hours; after the polymerization reaction is completed, centrifuge the product, It was washed several times with anhydrous ether and deionized water, and dried in vacuum at 318K for 12 hours to obtain polystyrene nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com