Acetobacter pasteurianus strain, microbial inoculum, application thereof and preparation method of edible vinegar

A technology of Acetobacter pasteurii and microbial agent, which is applied in the field of microbial agent and vinegar production method, can solve the problems of not being well adapted to the harsh environment of liquid fermentation, limited application of acetic acid bacteria, low organic acid content, etc., and achieves convenient Storage and application, good overall flavor and high acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Isolation and identification of bacterial strain Acetobacter pasteurianus HSCY1085

[0032] Among them, calcium carbonate, glucose, agar powder, absolute ethanol, acetic acid and sodium hydroxide were purchased from Sinopharm Chemical Reagent Co., Ltd.; yeast extract was purchased from OXOID Company in the United Kingdom.

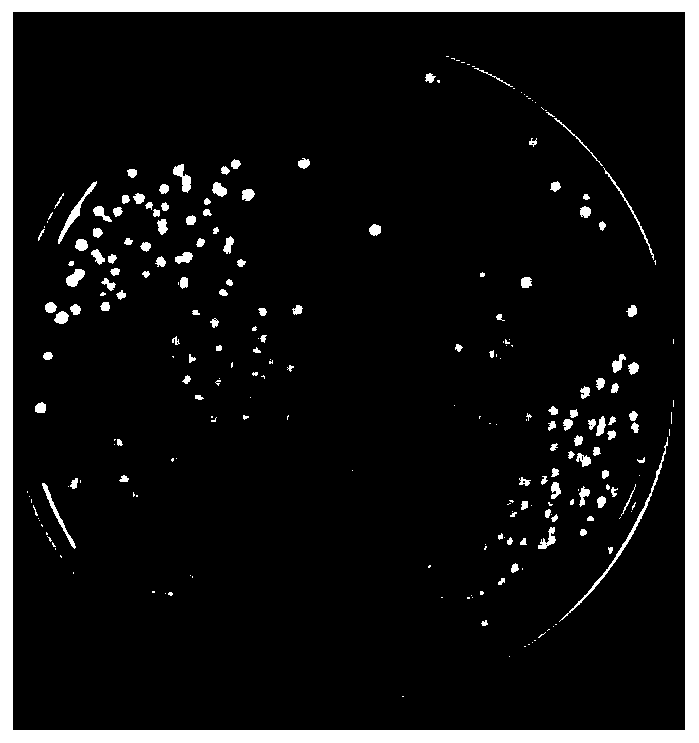

[0033] 1. Strain isolation

[0034] Take 10g of Zhenjiang balsamic vinegar unstrained spirits sample, add it to 90mL of sterilized normal saline, shake it well on a shaker, then take 100μL of the sample and add it to 900μL of normal saline, mix it in a vortex shaker, and then carry out gradient dilution. Mix well and spread on the solid medium with 20g of calcium carbonate added (each 1L contains 20g of glucose, 10g of yeast extract, 15g of agar powder, sterilized at 121°C for 20min, then cooled, and added with 3% ethanol), cultured at 30°C for 3 days . Observe whether there is a transparent circle on the plate, and pick the correspon...

Embodiment 2

[0042] Embodiment 2: Activation of Acetobacter pasteurianus HSCY1085 and preparation of seed solution

[0043] (1) Activation and expansion of bacteria

[0044] The strains stored in glycerol tubes were liquid-activated, that is, 1 mL was transferred into test tubes (containing 5 mL medium), and cultured at 30° C. at 180 rpm for 24 hours.

[0045] (2) Preparation of primary seed solution

[0046] Take 10mL of the above-mentioned culture solution and transfer it to a 250mL Erlenmeyer flask (filling volume 100mL) according to 10% inoculum size, and culture at 30°C, 220rpm, on a shaking table for 20h to prepare a first-grade seed solution.

[0047] (3) Preparation of secondary seed solution

[0048] The above-mentioned primary seed liquid was inserted into a 2L Erlenmeyer flask (liquid volume 1L) according to 10% inoculation amount, and cultivated on a shaking table at 30°C for 20h, and the number of viable bacteria reached 8.9×10 7 CFU / mL, the fermentation broth can be used f...

Embodiment 3

[0049] Embodiment 3: Activation of Acetobacter pasteurianus HSCY1085 and preparation of seed solution

[0050] (1) Activation and expansion of bacteria

[0051]The strains stored in glycerol tubes were liquid-activated, that is, 1 mL was transferred into test tubes (containing 5 mL of medium), cultured on a shaker at 30° C., 180 rpm, for 24 hours.

[0052] (2) Preparation of primary seed solution

[0053] Take 20mL of the above-mentioned culture solution and transfer it to a 250mL Erlenmeyer flask (100mL liquid volume) according to 20% inoculum size, and cultivate it on a shaking table at 35°C and 180rpm for 36h to prepare a first-class seed solution.

[0054] (3) Preparation of secondary seed solution

[0055] The above-mentioned primary seed liquid was inserted into a 2L Erlenmeyer flask (1L liquid volume) according to 20% inoculation amount, cultivated on a shaking table at 35°C for 24h, and the number of viable bacteria reached 5.4×10 7 CFU / mL, the fermentation broth ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com