Spherical molybdenum disulfide/copper sulfide nanometer composite material and preparation method thereof

A technology of nanocomposite materials and molybdenum disulfide, which is applied in the field of nanomaterials, can solve the problems that the morphology cannot be adjusted and the steps are cumbersome, and achieve the effects of good catalytic activity, good crystallinity and strong current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

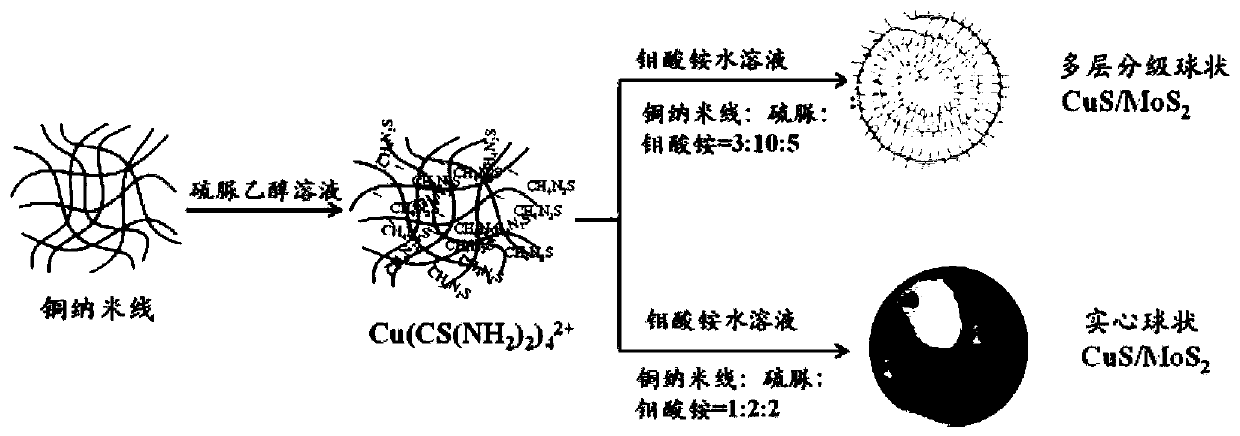

Method used

Image

Examples

Embodiment 1

[0043] (1) After centrifuging 12 mL of copper nanowire n-hexane dispersion (10 mg / mL) for 5 min (8000 rpm), suck the supernatant with a dropper, add 35 mL of ethanol, shake for 1 min to make it evenly dispersed, and then Centrifuge the solution for 5min (8000 rpm) to fully remove n-hexane, decant, repeat the above centrifugation-decantation steps two to three times, add 120mL ethanol, shake to make it fully dispersed into copper nanowire ethanol solution (1mg / mL);

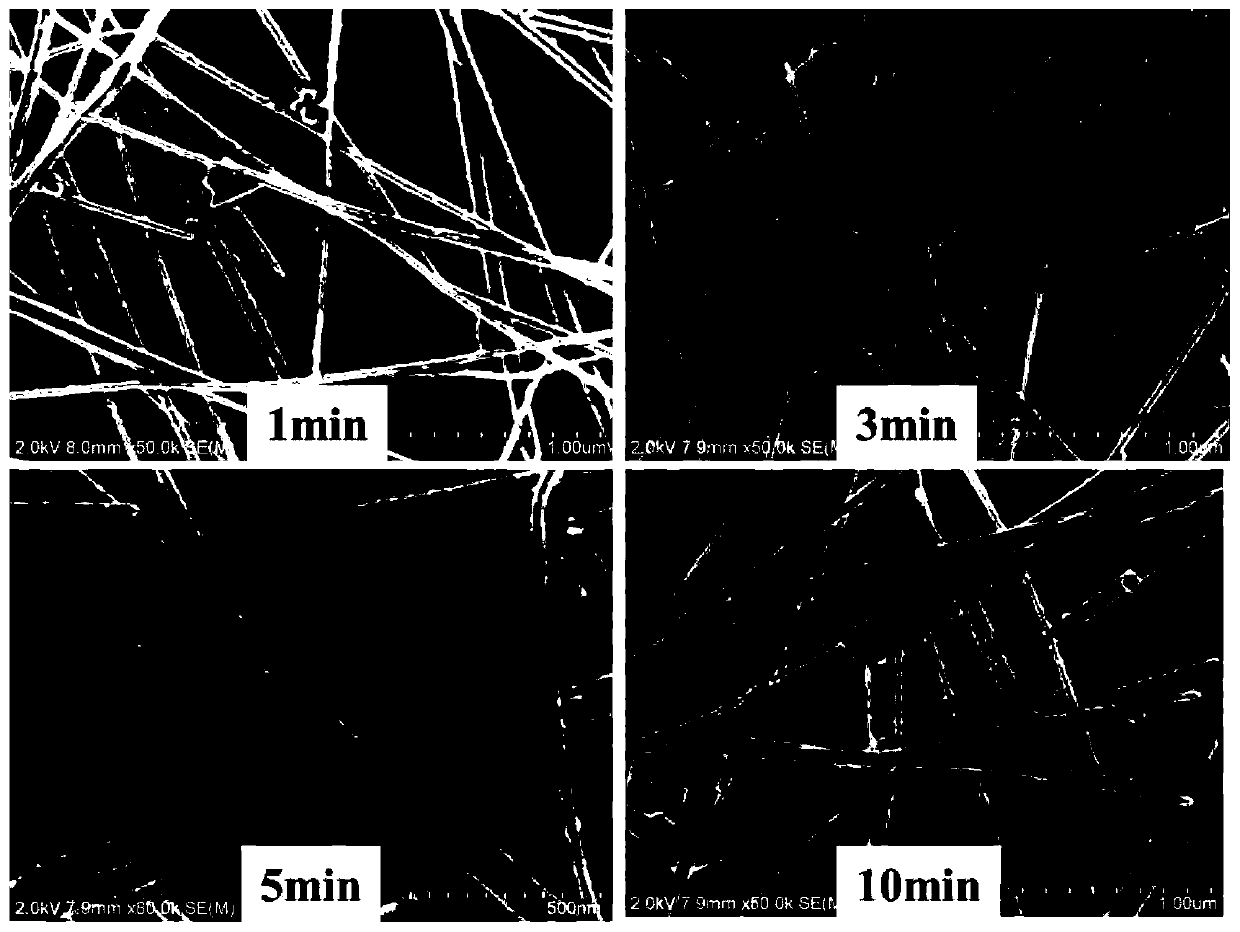

[0044](2) Take 2mL of copper nanowire ethanol solution (1mg / mL), sonicate for 1min, 3min, 5min, and 10min respectively, and take samples for scanning electron microscopy. The results are shown in figure 2 , it can be seen that when the ultrasound is 5 minutes, the copper nanowires are uniformly dispersed and not destroyed, therefore, 5 minutes is selected as the best ultrasonic time for copper nanowires;

[0045] (3) The total volume of the reaction system was controlled to be constant. For each group of experim...

Embodiment 2

[0060] (1) The total volume of the reaction system was controlled to be constant. For each group of experiments, the ethanol dispersion of copper nanowires was kept at 20 mL, the ethanol solution of thiourea was 2 mL, and the aqueous solution of ammonium molybdate was 2 mL. Control the concentration of copper nanowires to be 1.0, 0.7, 0.5, 0.3 mg / mL, the mass of thiourea to be 0.04, 0.02 g, and the mass ratio of thiourea to ammonium molybdate to be 1:1, 1.5:1, 2:1, Combination with each other, see Table 2 for detailed combination;

[0061] (2) Add ethanol solutions of thiourea with different masses and concentrations to copper nanowire ethanol dispersions of different masses and concentrations, and ultrasonically disperse for 3 minutes;

[0062] (3) Add aqueous solutions of thiourea with different masses and concentrations to the dispersion in (2), and disperse by ultrasonication for 2 minutes;

[0063] (4) Transfer the above solution to a polytetrafluoroethylene-lined stainl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com