Refining method of second phase chromium in chrome-copper immiscible alloy

A chemical synthesis method, copper-based composite material technology, applied in metal processing equipment, transportation and packaging, graphene and other directions, can solve the problems of reducing the electrical contact performance of alloys, single graphene addition process, etc., to achieve hardness improvement, electrical conductivity, etc. Enhanced, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

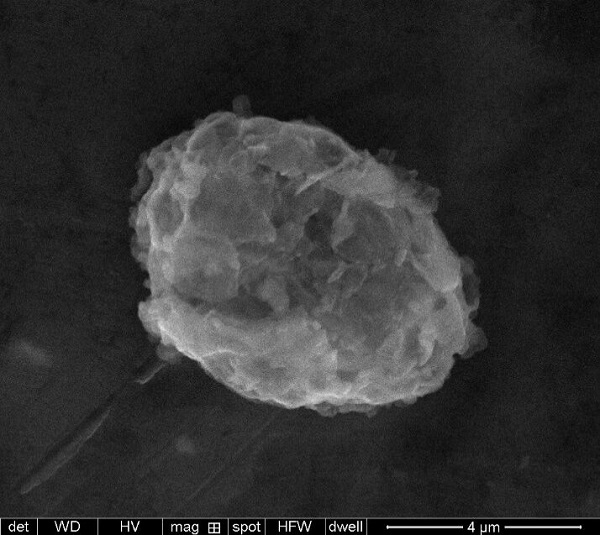

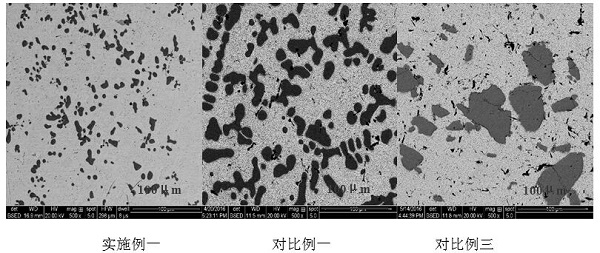

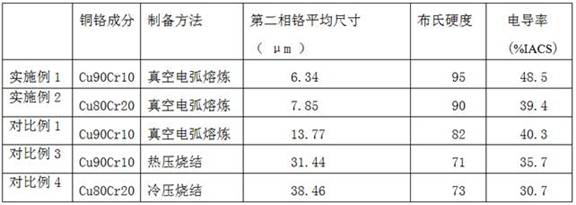

Embodiment 1

[0029] The mass fraction in the composite material is: 10% chromium powder, 90% copper powder, chromium powder purity 99.9%, particle size 1000 mesh; copper powder purity 99.9%, particle size 200 mesh; graphene oxide 1-3 layers, The particle size is 10 microns, and the added amount is 0.005% by mass of chromium powder. Prepare KH-550 silane coupling agent graphene oxide solution: alcohol-water ratio 0.5:15, KH-550 content is 1.0% by volume, stand for hydrolysis for 10 hours, add graphene oxide and stir ultrasonically for 30 minutes; Wash with ethanol and ultrasonically clean with deionized water twice, then use a centrifuge to carry out layering, select the chromium powder with a smaller particle size and uniform distribution in the upper layer to pass through a 1000-mesh sieve, pour the sieved chromium powder into 16.0g / L acetic acid, The pickling time is pickling in the pickling solution for 5s, and the deionized water is washed again after pickling; the silane coupling agen...

Embodiment 2

[0031]The mass fraction in the composite material is: 20% chromium powder, 80% copper powder, chromium powder purity 99.9%, particle size 1000 mesh; copper powder purity 99.9%, particle size 200 mesh; graphene oxide layers 1-3 layers , the particle size is 15 microns, and the added amount is 0.0013% of the mass fraction of chromium powder. Prepare KH-550 silane coupling agent graphene oxide solution: alcohol-water ratio 1:10, KH-550 content is 0.2% by volume, stand for hydrolysis for 4 hours, add graphene oxide and stir ultrasonically for 30 minutes; chromium powder is first used without Wash with water ethanol and ultrasonically clean with deionized water twice, then use a centrifuge to carry out layering, select the upper layer of chromium powder with a smaller particle size and uniform distribution, pass through a 1000-mesh sieve, pour the sieved chromium powder into 6.0g / L pickling Pickling in the solution, the pickling time is 20s, after pickling, the deionized water is w...

Embodiment 3

[0033] The mass fraction in the composite material is: 10% of chromium powder, 10% of copper powder, 1-5 layers of graphene oxide, and 0.002% of the mass fraction of chromium powder with a particle size of 5 microns. The purity of chromium powder is 99.9%, and the particle size is 1000 mesh; the purity of copper powder is 99.9%, and the particle size is 200 mesh; preparation of KH-550 silane coupling agent graphene oxide solution: alcohol-water ratio 5:15, KH-550 content is volume fraction 0.8%, stand for hydrolysis for 6 hours, add graphene oxide and ultrasonically stir for 40 minutes; chromium powder is washed with absolute ethanol and deionized water ultrasonically for two times, and then layered with a centrifuge to select the upper layer with a smaller particle size and uniform distribution The chromium powder is passed through a 1000-mesh sieve, and the sieved chromium powder is poured into 10.0g / L pickling solution for pickling, and the pickling time is 10s in the pickli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com