Comprehensive recovery method for zinc hydrometallurgy arsenic salt purification cobalt-nickel slag

A technology of hydrometallurgy and recovery method, which is applied to the improvement of process efficiency, photography process, instruments, etc., can solve the problems of waste water discharge, etc., and achieve the effect of simple process, beneficial to the purification of arsenic salt, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

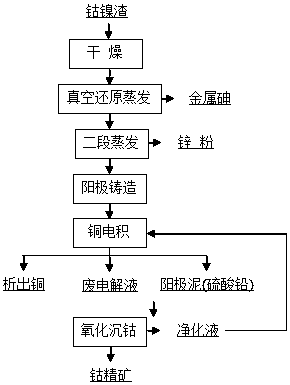

Image

Examples

Embodiment 1

[0027] Step A. Drying: Dry the cobalt-nickel slag purified from zinc arsenic salts by wet smelting under the protection of nitrogen. The drying temperature is 300°C, the drying time is 9h, the pressure is 30Pa, the oxygen concentration is 1.5%, and the moisture content of the dried material is 100%. Min content 0.5%.

[0028] Step B, vacuum reduction evaporation: mix the dried cobalt-nickel slag and 3% coking coal in the total weight percentage into a vacuum reduction furnace, the system pressure is 30Pa, the temperature is 500°C, and the time is 90min, to obtain arsenic metal powder; then Under the condition of constant pressure, the temperature was raised to 960°C for 60 minutes, and zinc powder was collected, and the bottom of the furnace was copper-cobalt-lead alloy.

[0029] Step C, copper electrowinning: cast copper-cobalt-lead alloy into an anode and put it into copper sulfate electrolyte for copper electrowinning, the electrolysis temperature is 50°C, and the current d...

Embodiment 2

[0033] Step A. Drying: Dry the cobalt-nickel slag purified by the wet-process zinc arsenic salt under the protection of argon. The drying temperature is 600°C, the drying time is 2h, the pressure is 80Pa, the oxygen concentration is 2.8%, and the moisture content of the dried material is The percentage content is 3.0%.

[0034]Step B. Vacuum reduction and evaporation: Mix the dried cobalt-nickel slag and 7% coking coal in the total weight percentage into the vacuum reduction furnace, the system pressure is 20Pa, the temperature is 700°C, and the time is 60min, to obtain arsenic metal powder; then Under the condition of constant pressure, the temperature was raised to 860°C for 90 minutes, and zinc powder was collected, and the bottom of the furnace was copper-cobalt-lead alloy.

[0035] Step C, copper electrowinning: cast copper-cobalt-lead alloy into an anode and put it into copper sulfate electrolyte for copper electrowinning, the cathode is a titanium plate, the electrolysi...

Embodiment 3

[0039] Step A. Drying: Dry the cobalt-nickel slag purified from zinc arsenic salts by wet smelting under the protection of carbon dioxide. The drying temperature is 500°C, the drying time is 5h, the pressure is 50Pa, the oxygen concentration is 2.5%, and the moisture content of the dried material is 100%. Min content 1.5%.

[0040] Step B. Vacuum reduction and evaporation: Mix the dried cobalt-nickel slag and 5% coking coal in the total weight percentage into a vacuum reduction furnace, the system pressure is 25Pa, the temperature is 600°C, and the time is 80min, to obtain arsenic metal powder; then Under the condition of constant pressure, the temperature was raised to 900°C for 80 minutes, and zinc powder was collected, and the bottom of the furnace was copper-cobalt-lead alloy.

[0041] Step C, copper electrowinning: cast copper-cobalt-lead alloy into an anode and put it into copper sulfate electrolyte for copper electrowinning, the electrolysis temperature is 60°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com