Method for preparing nano-scale alpha-type calcium sulfate hemihydrate whiskers from phosphogypsum in reverse microemulsion system

An inverse microemulsion, calcium sulfate hemihydrate technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problem that phosphogypsum has not seen relevant reports, and promote the utilization of high value-added resources. , the process is simple, the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

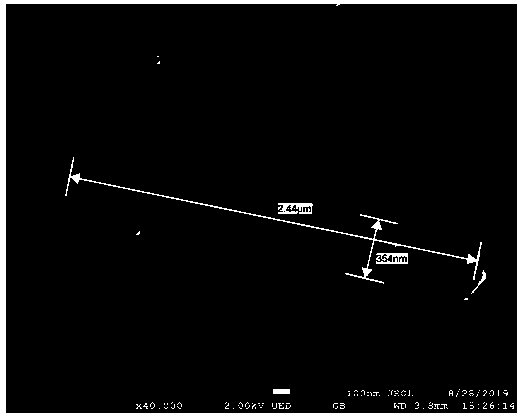

Embodiment 1

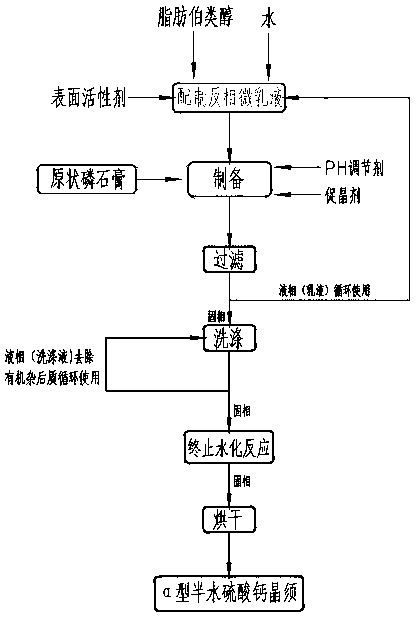

[0030] (1) Preparation of inverse microemulsion: Take 63 parts of n-hexanol, 30 parts of surfactant cetyltrimethylammonium bromide, and 7 parts of water into a beaker, stir with a constant speed stirrer until the emulsion is clear, and get 100 parts reverse phase microemulsion.

[0031] (2) Preparation of α-type calcium sulfate hemihydrate whiskers: Add 100 parts of inverse microemulsion and 15 parts of original phosphogypsum into a three-neck flask, add pH regulator magnesium hydroxide, and adjust the pH value of the emulsion to 6.8~7.2 , and then mixed with 0.56 parts of crystal accelerator calcium chloride according to 0.08% of the water consumption, and then placed on a temperature-controllable magnetic heating stirrer and heated at 105 ° C for 4 hours, and an external condensation device was used to avoid water evaporation to ensure the three-necked flask. Liquid phase equilibrium.

[0032] (3) After the reaction, take out the three-necked flask, pour the emulsion into a...

Embodiment 2

[0035] (1) Preparation of inverse microemulsion: Take 69 parts of n-hexanol, 26 parts of surfactant cetyltrimethylammonium bromide, and 5 parts of water into a beaker, stir with a constant speed stirrer until the emulsion is clear, and get 100 parts reverse phase microemulsion.

[0036] (2) Preparation of α-type calcium sulfate hemihydrate whiskers: Add 100 parts of inverse microemulsion and 22.5 parts of original phosphogypsum into a three-necked flask, add pH regulator magnesium hydroxide, and adjust the pH value of the emulsion to 6.8~7.2 , and then mixed with 0.575 parts of crystal accelerator magnesium chloride according to 0.115% of the water consumption, and then placed on a temperature-controllable magnetic heating stirrer and heated at 95 ° C for 3 hours, and an external condensation device was used to avoid water evaporation, so as to ensure the liquid phase in the three-necked flask balance.

[0037] (3) After the reaction, take out the three-necked flask, pour the...

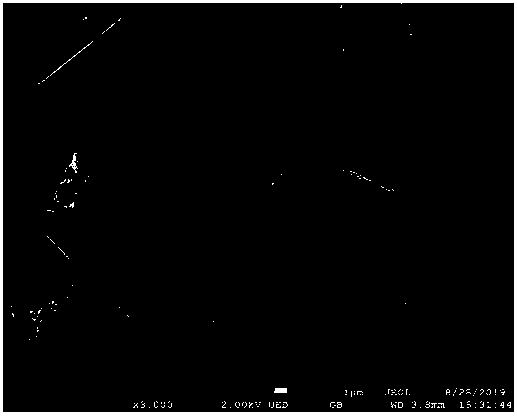

Embodiment 3

[0040] (1) Preparation of reverse-phase microemulsion: Take 72 parts of n-amyl alcohol, 25 parts of surfactant polyethylene glycol, and 3 parts of water into a beaker, stir with a constant speed stirrer until the emulsion is clear, and obtain 100 parts of reverse-phase microemulsion. lotion.

[0041] (2) Preparation of α-type calcium sulfate hemihydrate whiskers: Add 100 parts of inverse microemulsion and 30 parts of original phosphogypsum into a three-necked flask, add pH regulator sodium hydroxide, and adjust the pH value of the emulsion to 6.8~7.2 , and then mixed with 0.45 parts of crystal accelerator magnesium chloride according to 0.15% of the water consumption, and then placed on a temperature-controllable magnetic heating stirrer and heated at 85 ° C for 2 hours, and an external condensation device was used to avoid water evaporation, so as to ensure the liquid phase in the three-necked flask balance.

[0042] (3) After the reaction, take out the three-necked flask, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aspect ratio | aaaaa | aaaaa |

| Aspect ratio | aaaaa | aaaaa |

| Aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com