Method for extracting ganoderma triterpenes by continuous phase transition and ganoderma triterpenes

A Ganoderma lucidum triterpenes and extraction technology, which is applied in solid solvent extraction, pharmaceutical formulations, medical preparations containing active ingredients, etc., can solve the problems of destroying heat-sensitive active substances of Ganoderma lucidum, low extraction rate, and small injection volume, etc., and achieve reduction Loss of low boiling point components, improved extraction rate, fast action effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

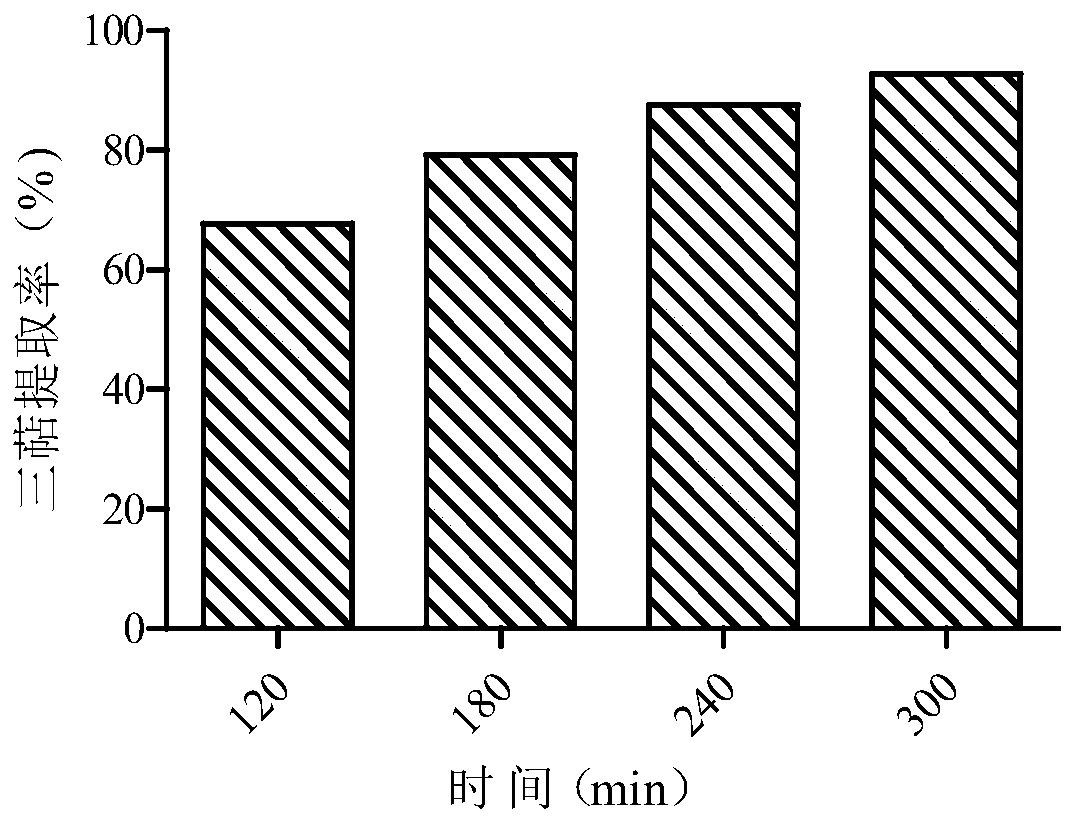

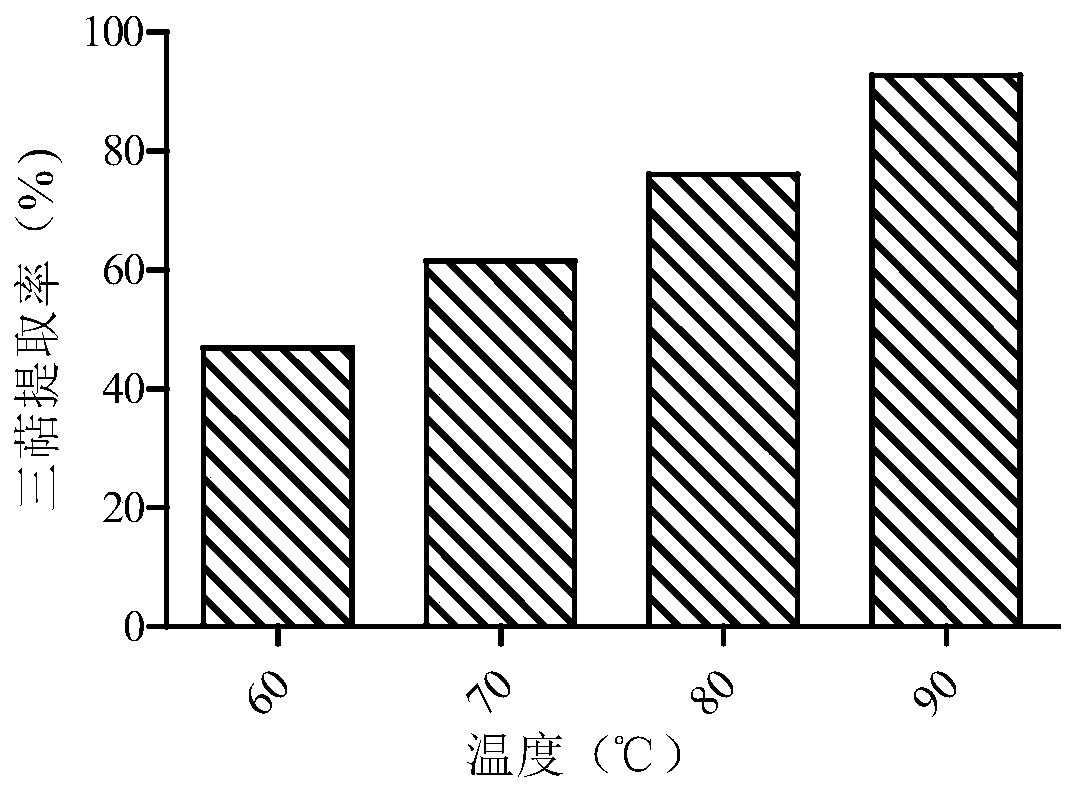

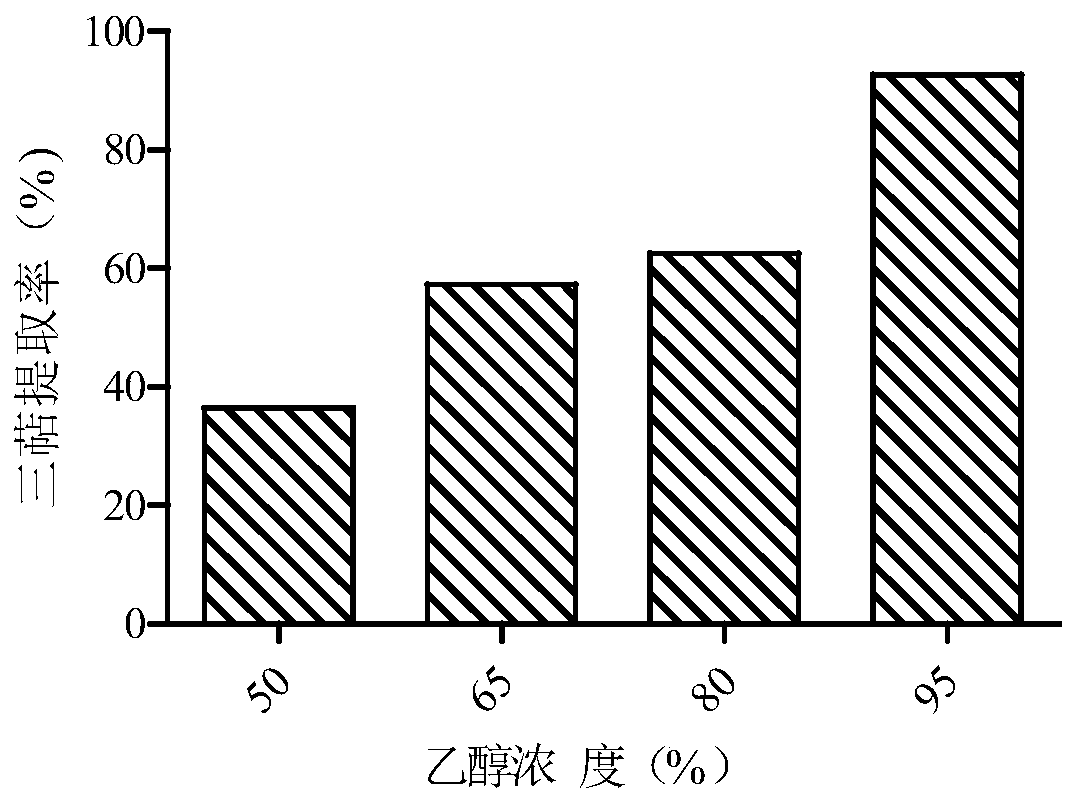

[0037] Example 1 Ganoderma lucidum triterpenes continuous phase change extraction process research experiment

[0038] 1. Single factor experiment.

[0039] (1) Method

[0040] According to the characteristics of ganoderma lucidum raw materials, the present invention continuously analyzes and determines and adjusts the technological conditions. Follow the steps below:

[0041] 1) Continuous phase-change phase-change extraction of Ganoderma lucidum polysaccharides: dry the dried Ganoderma lucidum in a block at 55°C, control the moisture content to ≤15%, crush it to an appropriate mesh size, and obtain Ganoderma lucidum powder; add the Ganoderma lucidum powder to 20L In the extraction kettle, use the extractant as pure water, extract for 60 min at the extraction temperature of 60°C, the extraction pressure of 0.20MPa, and the extraction flow rate of 100L / h. Analysis is carried out under the analysis conditions to obtain Ganoderma lucidum polysaccharide;

[0042] 2) Continuou...

Embodiment 2

[0060] Embodiment 2 A kind of method of continuous phase change extraction ganoderma triterpenes

[0061] (1) Ganoderma lucidum is sliced and crushed and then dried until the water content is ≤15% to obtain Ganoderma lucidum powder, and the polysaccharides are extracted through continuous phase change phase change to obtain the ganoderma lucidum dregs, and dried to control the moisture content in the ganoderma lucidum dregs to be less than or equal to 25%;

[0062] Among them, the extraction conditions of continuous phase-change phase-change extraction of polysaccharides are: the extraction agent is pure water, the extraction temperature is 60 ° C, the extraction pressure is 0.20 MPa, and the extraction flow rate is 100 L / h. Analysis is carried out under the analysis conditions of 65°C and analysis pressure of 0.10 MPa, and the extraction rate of Ganoderma lucidum polysaccharide is 35%-41.20%;

[0063] (2) Add 2000 g of the above-mentioned Ganoderma lucidum slag into a 20L e...

Embodiment 3

[0065] Embodiment 3 A kind of method of continuous phase change extraction ganoderma triterpenes

[0066] (1) Ganoderma lucidum is sliced and pulverized and then dried until the water content is ≤15% to obtain Ganoderma lucidum powder. According to the same conditions as in Example 2, after the polysaccharide is extracted by continuous phase change phase change, the ganoderma lucidum residue is obtained, dried, and controlled Moisture content in ganoderma residue ≤ 25%;

[0067] (2) Add 2000 g of the above-mentioned Ganoderma lucidum slag into a 20L extraction kettle, use ethanol aqueous solution as the extractant of Ganoderma lucidum triterpenoids, set the ethanol aqueous solution concentration as 75%, extraction temperature at 60°C, pressure at 0.10MPa, and extraction flow rate at 40L / h, Pour ethanol aqueous solution into the extraction kettle, and extract continuously for 180 minutes; control the solid-liquid ratio of Ganoderma lucidum residue and extractant to 1:30g / mL; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com