Preparation method of composite adsorption-type solid water reducing agent for sulphoaluminate cement

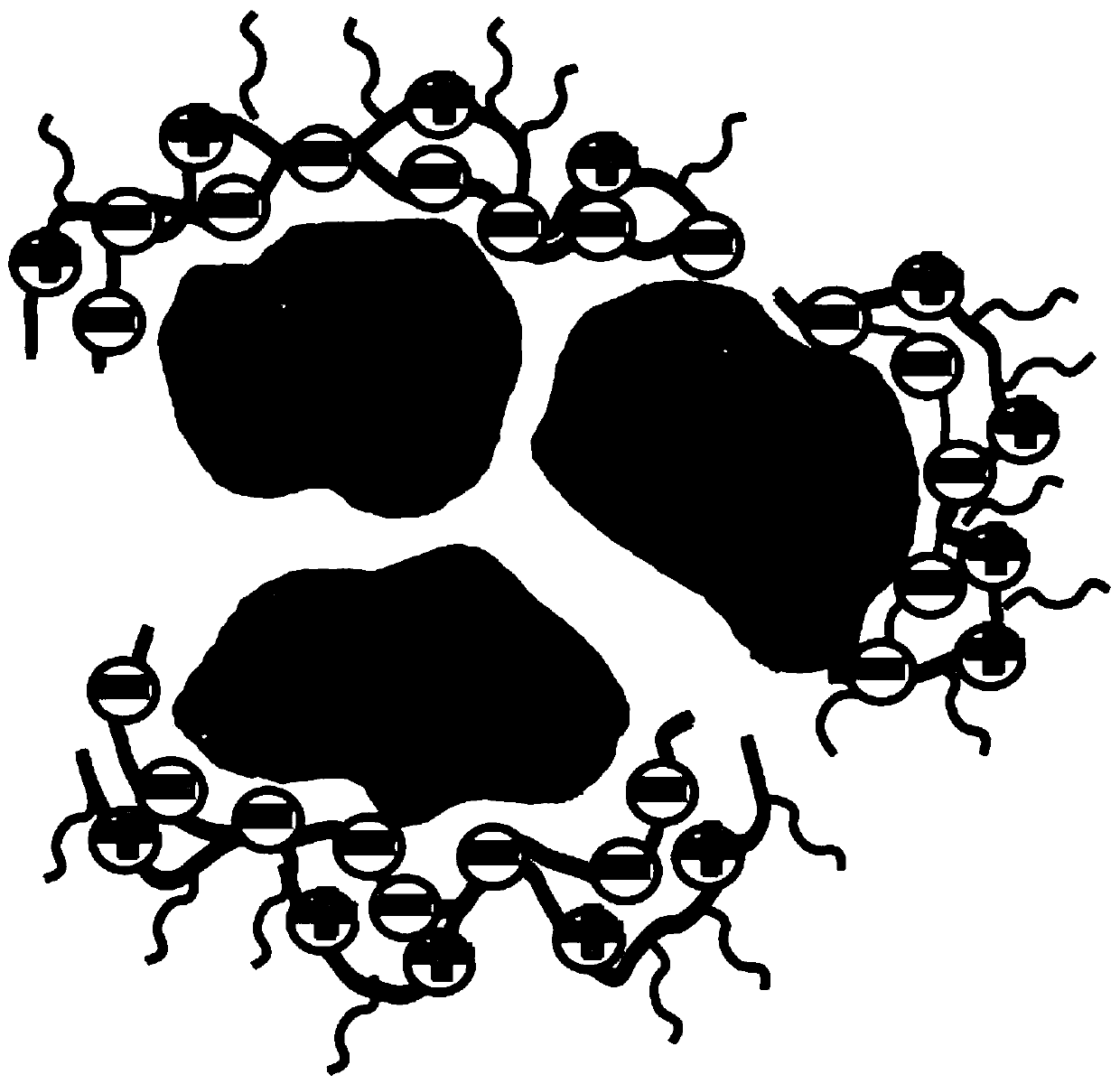

A technology of sulfoaluminate cement and composite adsorption, which is applied in the field of solid water reducing agent to achieve excellent setting retardation effect, improve dispersibility and delay generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

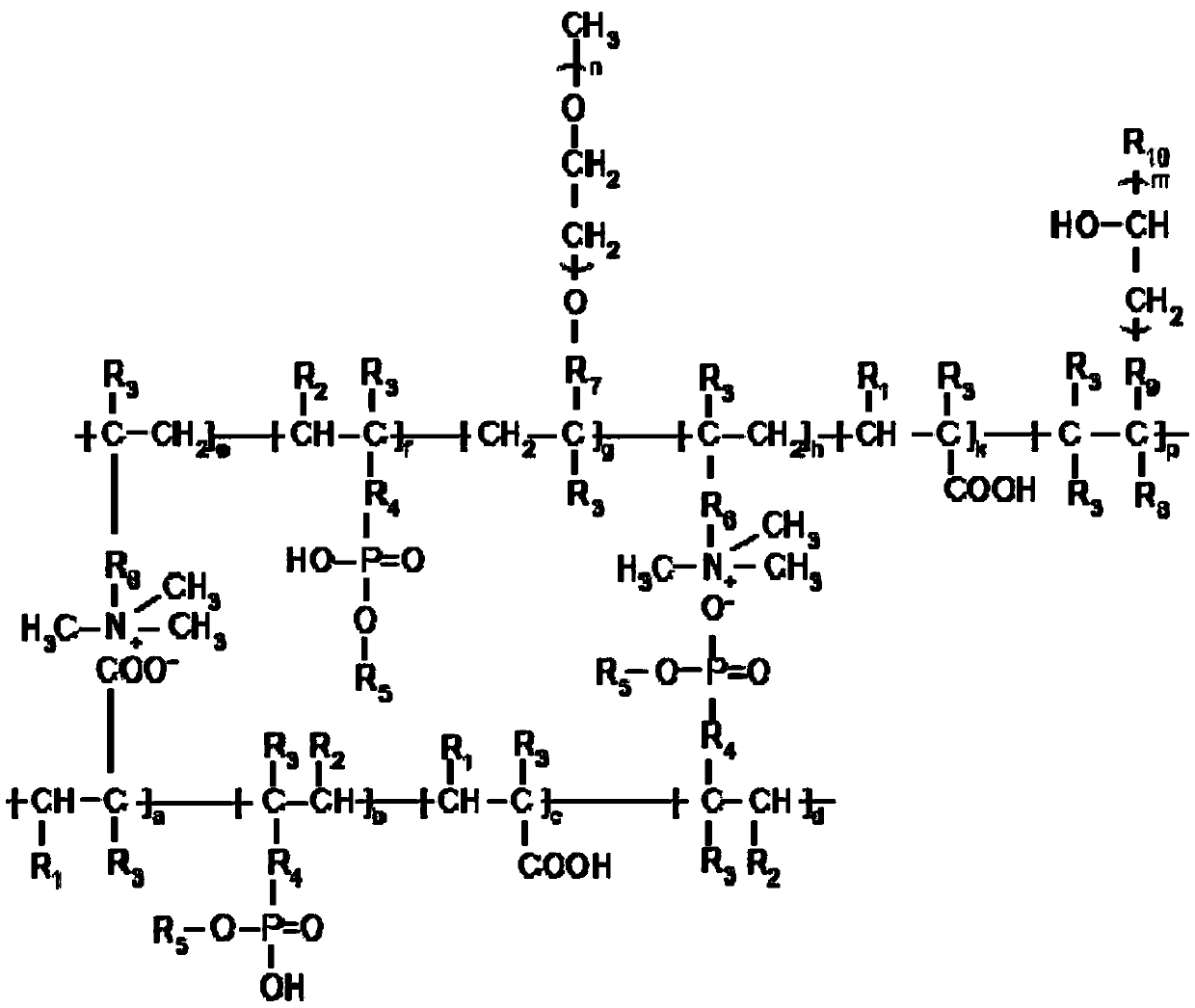

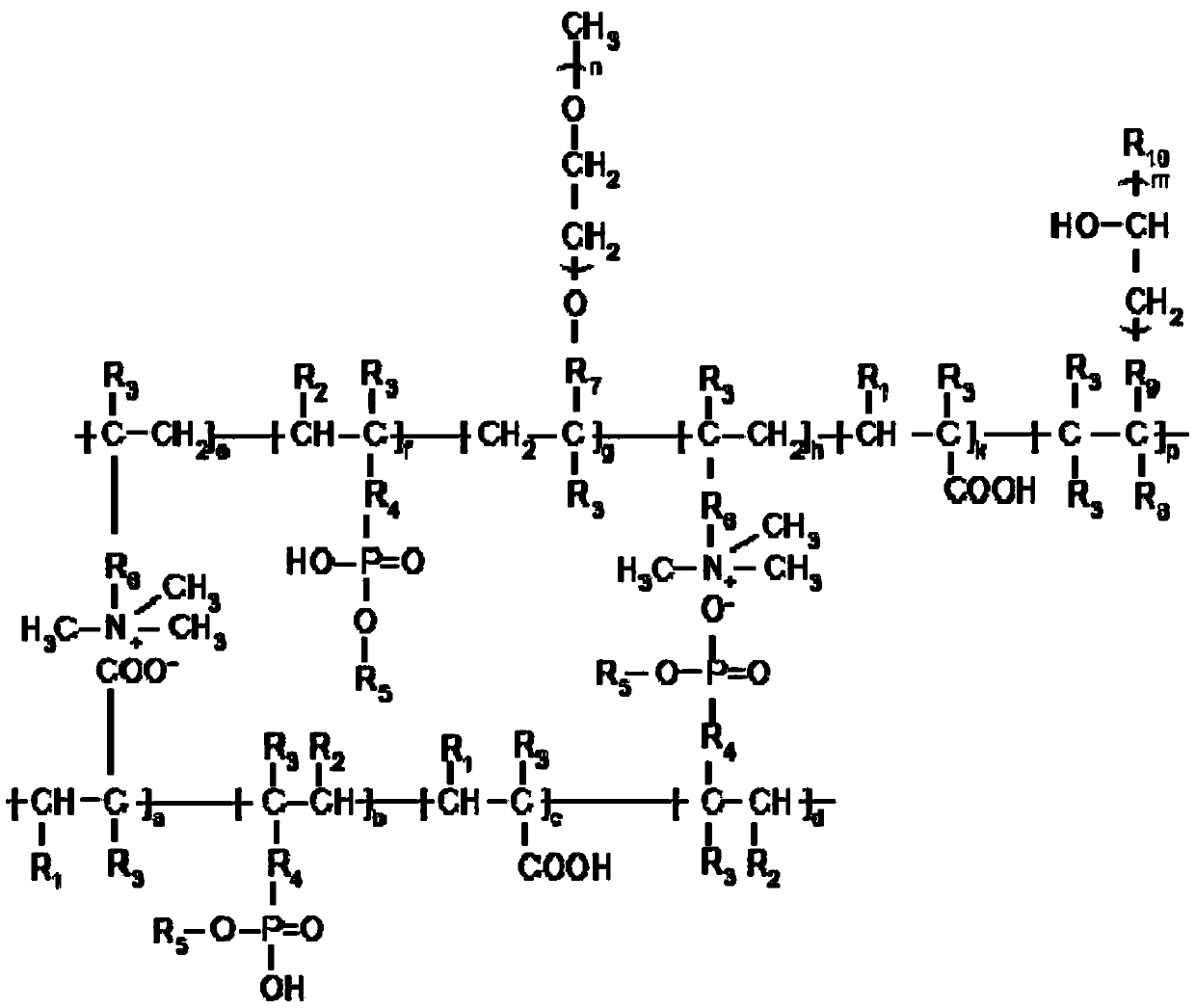

Method used

Image

Examples

Embodiment 1

[0031] First, 5.76g of acrylic acid was added to the reactor, stirred and heated to 120°C, and then a mixed solution of 17.84g of phosphonic acid-B-styryl ester, 0.31g of mercaptoethanol and 0.892g of methylamine was added dropwise for 3 hours, and divided into 12 Add 0.73g of ammonium persulfate at a time, and the stirring time is 5 minutes between each addition, continue the constant temperature reaction for 1 hour after the dropwise addition, stop the reaction, cool to 15°C, and obtain a linear solid water reducer; then add 8.609g of vinyl acetate Mix well with 86.09g of toluene, add 1.21g of allyl bromide, 4.305g of cuprous bromide, 6.8508g of N,N,N,N,N-pentamethyldivinyltriamine, and treat with nitrogen gas three times under ice-water bath After deoxygenation for 5 minutes, stir for 15 minutes until it is evenly mixed, under nitrogen protection, heat up to 30°C for polymerization reaction, react for 3 hours, desalt and vacuum distillation to remove toluene, add 12.816g of ...

Embodiment 2

[0033]First, 8.26g of methacrylic acid was added to the reactor, stirred and heated to 80°C, then 13.13g of 10-(2-methacryloyloxy) monodecyl phosphate, 0.52g of thioglycolic acid and 0.788g of urea were added dropwise Mix the solution for 4 hours, add 0.97g potassium persulfate in 15 times, and stir for 8 minutes between each addition, continue the constant temperature reaction for 3 hours after the dropwise addition, stop the reaction, cool to 15°C, and obtain a linear solid water reducer ; Next, mix 50.06g vinyl propionate and 400g p-xylene evenly, add 0.9055g methallyl chloride, 1.485g cuprous chloride, 2.3427g 2,2-bipyridine, and process 5 times with nitrogen in an ice-water bath After deoxygenation for 8 minutes, stir for 30 minutes until it is evenly mixed, under the protection of nitrogen, heat up to 50°C for polymerization reaction, react for 8 hours, desalt and vacuum distillation to remove p-xylene, add 103.6575g of ethanol, stir and heat up to 40 ℃, add 0.378g potas...

Embodiment 3

[0035] First, 11.76g of acrylic acid was added to the reactor, stirred and heated to 60°C, and then a mixed solution of 14.73g of phosphonic acid-B-styryl ester, 0.84g of mercaptopropionic acid and 1.03g of ethylamine was added dropwise for 6 hours. Add 0.95g of sodium persulfate 10 times, and the stirring time is 10 minutes between each addition, continue the constant temperature reaction for 4 hours after the dropwise addition, stop the reaction, cool to 20°C, and obtain a linear solid water reducer; then add 114.14g of butyric acid Mix vinyl ester and 570.7g dimethylformamide evenly, add 1.4903g 1-bromo 3-methyl-2-butene, 8.626g ferrous bromide, 13.8234g 1,1,4,7,10,10-hexamethyl Triethylenetetramine, treated with nitrogen in an ice-water bath for 4 times and deoxygenated for 10 minutes, stirred for 25 minutes until it was mixed evenly, and then heated to 60°C under the protection of nitrogen to carry out polymerization reaction, reacted for 12 hours, desalted and distilled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com