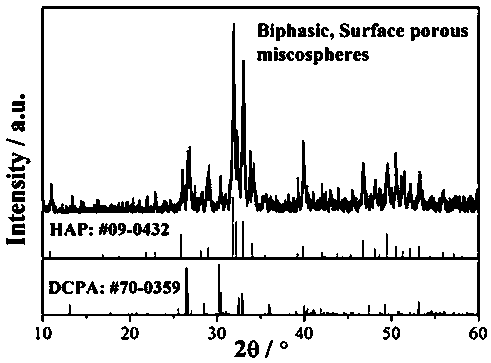

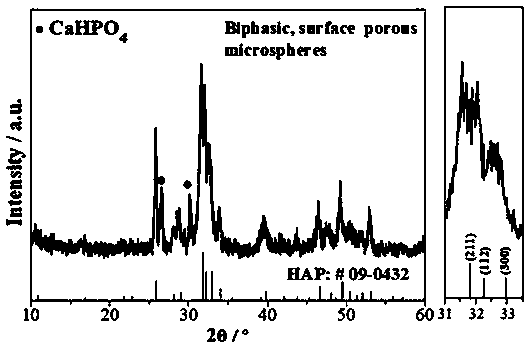

Anhydrous calcium hydrophosphate/hydroxyapatite biphasic porous microsphere material, and preparation method and application thereof

An anhydrous calcium hydrogen phosphate, hydroxyapatite technology, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve the problem of poor process repeatability and product morphology stability, low adjustable temperature range, and reaction time. It can improve the biomineralization ability, good degradability, and promote cell proliferation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] An anhydrous calcium hydrogen phosphate / hydroxyapatite dual-phase porous microsphere material, the specific preparation steps are as follows:

[0037] (1) Prepare a mixed solution of calcium salt, phosphorus salt, sedimentation agent and nucleating agent; the calcium salt used is calcium nitrate and calcium chloride mixed at a mass ratio of 1:1, and the concentration of calcium salt in the mixed solution is 0.05mol / L; Phosphate salt is a mixture of potassium dihydrogen phosphate and sodium dihydrogen phosphate at a mass ratio of 1:1, and the concentration of phosphorus salt in the mixture is 0.03mol / L; the precipitant is concentrated ammonia water with a mass fraction of 25-28%. The concentration of ammonia in the liquid is 0.2mol / L;

[0038] (2) Select concentrated nitric acid with a mass fraction of 86-97.5% to adjust the pH value of the mixture in step (1) to 2.5;

[0039] (3) Put the mixed liquid in step (2) into the reactor, the mixed liquid accounts for 70% of t...

Embodiment 2

[0044] An anhydrous calcium hydrogen phosphate / hydroxyapatite dual-phase porous microsphere material, the specific preparation steps are as follows:

[0045] (1) Configure a mixed solution of calcium salt, phosphorus salt, sedimentation agent and nucleating agent; the calcium salt used is calcium nitrate, and the concentration of calcium salt in the mixed solution is 0.167mol / L; the phosphorus salt is diammonium hydrogen phosphate, The concentration of phosphorus salt in the mixed solution is 0.1mol / L; the precipitating agent is urea, the concentration of urea in the mixed solution is 0.7mol / L, the nucleating agent is strontium nitrate, and the addition amount is 20% of the molar amount of calcium salt;

[0046] (2) Select concentrated ammonia water with a mass fraction of 25-28% to adjust the pH value of the mixture in step (1) to 3;

[0047] (3) Put the mixed liquid in step (2) into the reactor, the mixed liquid accounts for 40% of the effective volume of the reactor, and ca...

Embodiment 3

[0052] An anhydrous calcium hydrogen phosphate / hydroxyapatite dual-phase porous microsphere material, the specific preparation steps are as follows:

[0053] (1) Prepare a mixed solution of calcium salt, phosphorus salt, sedimentation agent and nucleating agent; the calcium salt used is a mixture of calcium hydroxide and calcium hydrogen phosphate at a mass ratio of 1:1, and the concentration of calcium salt in the mixed solution is 2mol / L; Phosphorus salt is a mixture of phosphoric acid and ammonium phosphate at a mass ratio of 1:1, and the concentration of phosphorus salt in the mixed solution is 1.25mol / L; the precipitating agent is urea, and the concentration of urea in the mixed solution is 2.5mol / L, and the nucleating agent is Magnesium chloride and strontium chloride are added in an amount of 0.01% and 0.03% of the molar amount of the calcium salt, respectively;

[0054] (2) Select concentrated nitric acid with a mass fraction of 86-97.5% to adjust the pH value of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com