A metal selenium compound negative electrode material for lithium/sodium ion battery, preparation method and application

A sodium-ion battery, selenium compound technology, applied in metal selenide/telluride, binary selenium/tellurium compound, battery electrodes, etc., can solve the problems of unsatisfactory cycle performance and rate performance, and achieve low cost and reversible ratio. The effect of high capacity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

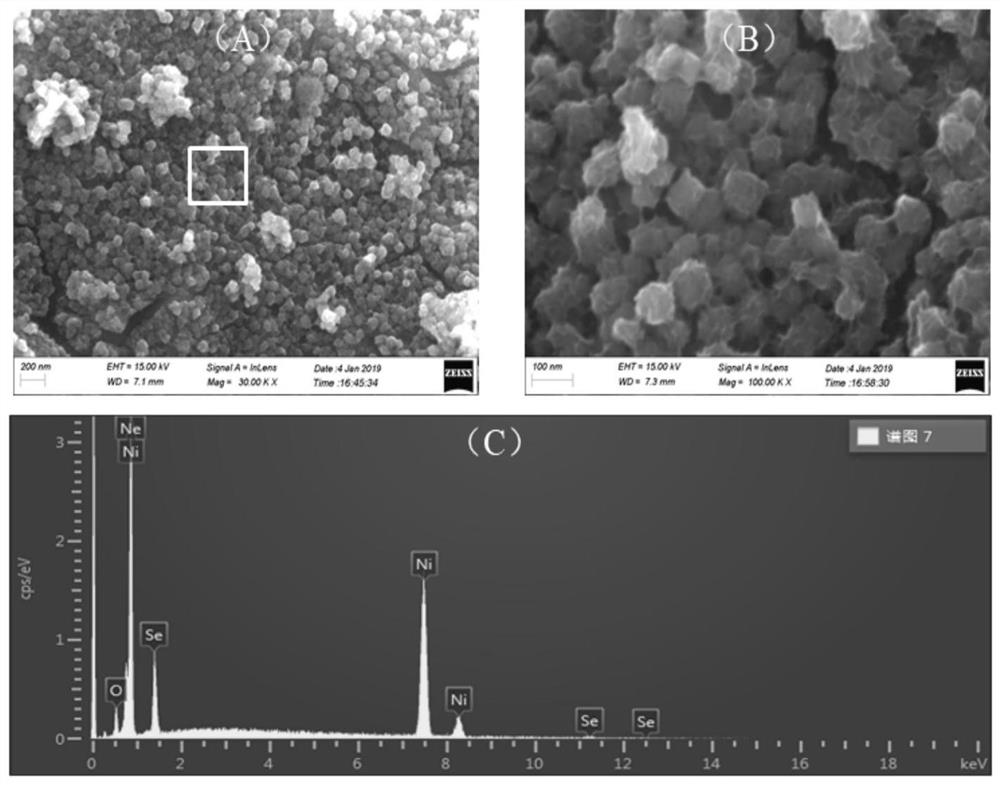

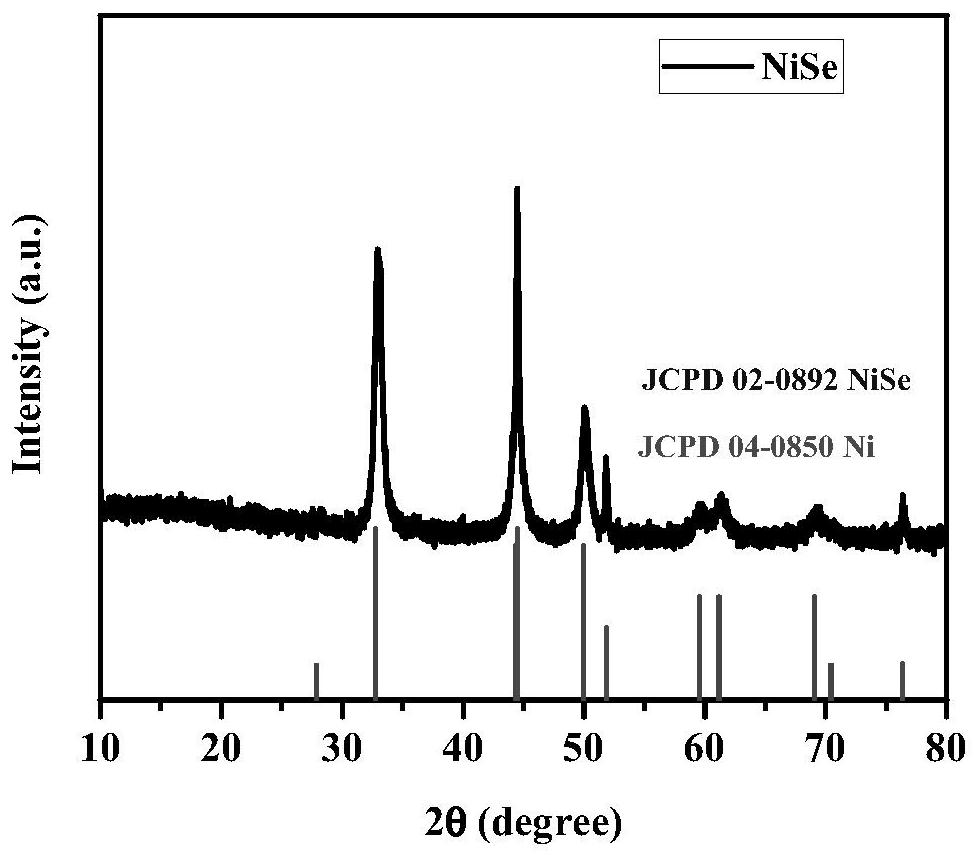

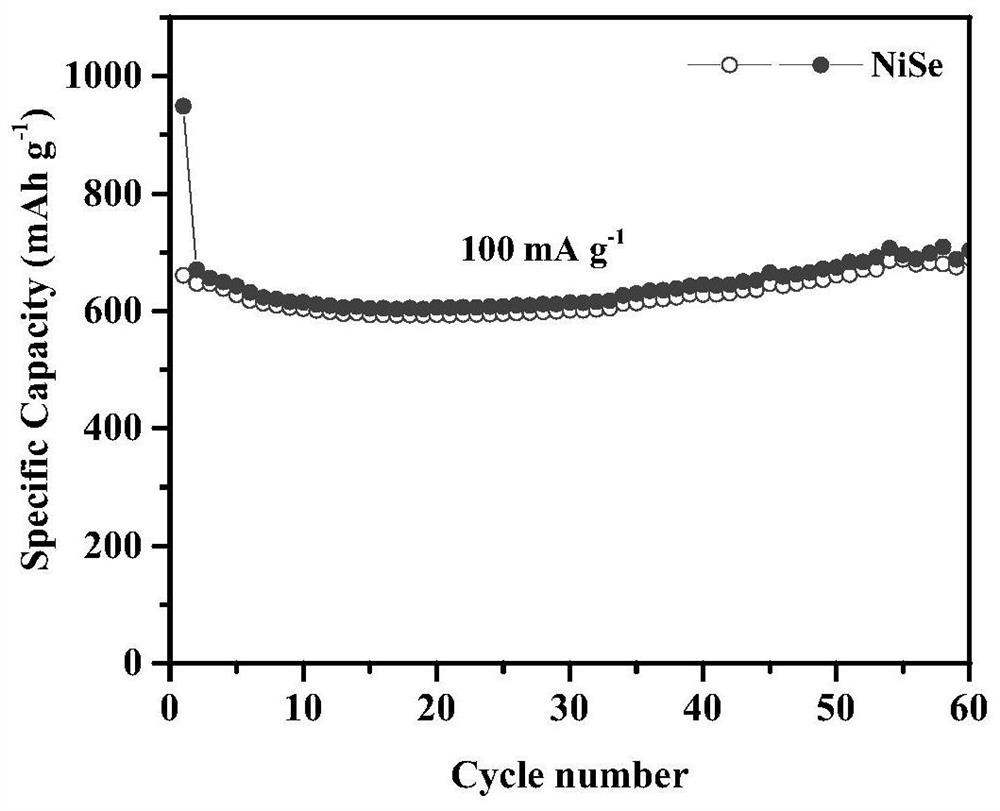

[0039] The preparation steps of NiSe negative electrode material are as follows:

[0040] 1) First cut the nickel foam into a size of 3.6×3.6cm, put it into 20mL deionized water for ultrasonic cleaning, and then dry it;

[0041] 2) put the dried nickel foam into 20mL of 1mol / L hydrochloric acid solution for three minutes and sonicate for acidification;

[0042] 3) The nickel foam after the acidification treatment was rinsed with deionized water, put into 20mL deionized water for ultrasonic cleaning for three minutes, and then dried;

[0043] 4) Put 0.52g of sodium selenite and 2g of anhydrous glucose into 50ml of deionized water for ultrasonic dissolution to obtain a mixed solution;

[0044] 5) Then put the dry nickel foam into the mixed solution for three minutes of ultrasonic treatment;

[0045] 6) After ultrasonication, put the mixed solution and nickel foam together into a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into an electric constant t...

Embodiment 2

[0048] The preparation steps of CuSe negative electrode material are as follows:

[0049] 1) First cut the foamed copper into 3.6×3.6cm size, put it into 20mL deionized water, ultrasonically clean it, and then dry it;

[0050] 2) Put the dried copper foam into 20mL of 1mol / L hydrochloric acid solution for three minutes and sonicate for acidification;

[0051] 3) Rinse the acidified copper foam with deionized water, put it into 20mL deionized water for ultrasonic cleaning for three minutes, and then dry it;

[0052] 4) Put 0.52g of sodium selenite and 2g of ethylenediamine together into 50ml of deionized water for ultrasonic dissolution to obtain a mixed solution;

[0053] 5) Then put the dry copper foam into the mixed solution for three minutes of ultrasonic treatment;

[0054] 6) After ultrasonication, put the mixed solution and copper foam together into the hydrothermal reaction kettle, then put the hydrothermal reaction kettle into the electric constant temperature blast dr...

Embodiment 3

[0057] The preparation steps of CoSe negative electrode material are as follows:

[0058] 1) First cut the cobalt foam into a size of 3.6×3.6cm, put it into 20mL deionized water for ultrasonic cleaning, and then dry it;

[0059] 2) put the dried foamed cobalt into 20mL of 1mol / L hydrochloric acid solution and sonicate for three minutes for acidification;

[0060] 3) The acidified cobalt foam was rinsed with deionized water, put into 20mL deionized water for ultrasonic cleaning for three minutes, and then dried;

[0061] 4) Put 0.52g of sodium selenite and 2g of hydrazine hydrate together into 50ml of deionized water for ultrasonic dissolution to obtain a mixed solution;

[0062] 5) Then put the dried cobalt foam into the mixed solution for three minutes of ultrasonic treatment;

[0063] 6) After ultrasonication, put the mixed solution and cobalt foam together into a hydrothermal reaction kettle, then put the hydrothermal reaction kettle into an electric constant temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com