Preparation method of nest-shaped nitrogen-doped negative electrode porous carbon material

A technology of porous carbon materials and nitrogen doping, applied in chemical instruments and methods, carbon compounds, hybrid capacitor electrodes, etc., can solve the problems of time-consuming, high cost, unsuitable for large-scale production, etc. The effect of short time and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

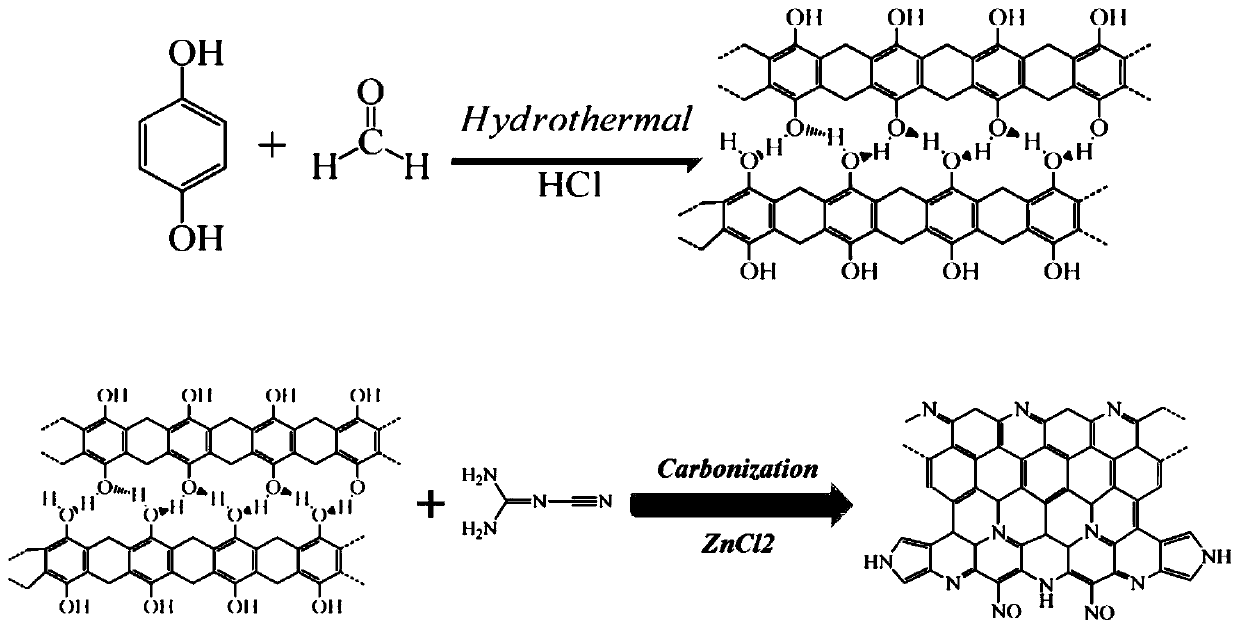

[0035] Embodiment 1: A kind of preparation method of bird's nest nitrogen-doped negative electrode porous carbon material, comprises the following preparation steps:

[0036] 1) Mix 0.825g of hydroquinone and 1.25ml of 37wt% formaldehyde solution, add 10wt% hydrochloric acid solution, and stir well to obtain a mixed solution with a pH of 2;

[0037] 2) Transfer the mixed solution to a polytetrafluoroethylene-lined autoclave, and react at 180°C for 14 hours to prepare a reaction solution;

[0038] 3) The reaction solution was taken out, cooled naturally at room temperature, and then centrifuged at 8000rpm for 6min to obtain a precipitate;

[0039] 4) The precipitate was washed with water until the pH was 7, and then placed in an oven and dried under vacuum at 70°C for 18 hours to obtain a linear polymer nanobelt precursor (CsPNB);

[0040] 5) The linear polymer nanoribbon precursor (CsPNB) was mixed and ground with dicyandiamide and zinc chloride at a mass ratio of 1:1:2.5, an...

Embodiment 2

[0041] Embodiment 2: A preparation method of a bird's nest nitrogen-doped negative electrode porous carbon material, comprising the following preparation steps:

[0042] 1) Mix 0.94g of phenol and 0.81ml of 37wt% formaldehyde solution, add 10wt% sulfuric acid solution, stir well to obtain a mixed solution with a pH of 1;

[0043] 2) Transfer the mixed solution to a polytetrafluoroethylene-lined autoclave, and react at 160°C for 16 hours to prepare a reaction solution;

[0044] 3) Take out the reaction solution, cool it naturally at room temperature, and then centrifuge at 12000rpm for 3min to obtain a precipitate;

[0045] 4) The precipitate was washed with water until the pH was 7.5, and then placed in an oven at 60°C for 24 hours under vacuum to obtain a linear polymer nanobelt precursor (CsPNB);

[0046] 5) Mix and grind the linear polymer nanoribbon precursor (CsPNB) with dicyandiamide and zinc chloride at a mass ratio of 1:1:2, then place it in an argon atmosphere at 50m...

Embodiment 3

[0047] Embodiment 3: a kind of preparation method of bird's nest nitrogen-doped negative electrode porous carbon material, comprises the following preparation steps:

[0048] 1) Mix 0.33g of catechol and 2.43ml of 37wt% formaldehyde solution, add 15wt% nitric acid solution, and stir well to obtain a mixed solution with a pH of 4;

[0049] 2) Transfer the mixed solution to a polytetrafluoroethylene-lined autoclave, and react at 220°C for 12 hours to prepare a reaction solution;

[0050] 3) Take out the reaction solution, cool it naturally at room temperature, and then centrifuge at 5000rpm for 10min to obtain a precipitate;

[0051] 4) The precipitate was washed with water until the pH was 6.5, and then placed in an oven at 80°C for 12 hours in vacuum to obtain a linear polymer nanobelt precursor (CsPNB);

[0052] 5) Mix and grind the linear polymer nanoribbon precursor (CsPNB) with dicyandiamide and zinc chloride at a mass ratio of 1:1:3, then place it in an argon atmosphere ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com